|

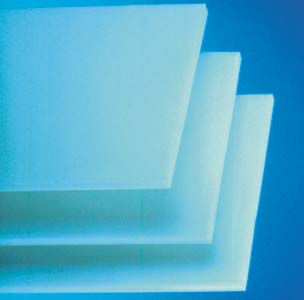

ACETAL COPOLYMER IN FOUR FOOT SHEETS

ACETECH XLS™ from A.L. Hyde, an easy

to machine, extremely low stress acetal copolymer that improves part yield and

allows tighter tolerances, is now available in 4' sheets. Representative of the

latest in plastics technology, ACETECH XLS consistently measures lower in stress

than materials currently on the market. It exceeds requirements for physical

properties, stress, and centerline porosity per ASTM D 6100 S-POM0211, LP.

The materials features include no

centerline porosity, excellent dimensional stability, outstanding wear

properties and good chemical resistance. These characteristics assure

outstanding appearance, mechanical integrity, and proven consistent performance.

Suitable for use in food processing applications, ACETECH XLS complies with FDA

requirements for direct food contact. Slab is available in thicknesses ranging

from 3/8" to 2".

The acetal copolymer is ideal for machining

a wide variety of parts. For very intricate parts, lower stress and better

dimension stability means less warping. It is also an excellent choice to

replace materials such as steel, brass, bronze, and aluminum to help reduce part

weight, improve wear or chemical resistance, and reduce factory noise, or the

need for lubricants. Less warping, combined with no centerline porosity, will

result in parts with outstanding appearance and mechanical integrity.

A product data sheet containing testing

information and physical property performance is available.

For more information, contact Bruce Dickinson, A.L. Hyde Company, 1 Main Street,

Grenloch, NJ 08032, 800-234-HYDE (4933), 856-227-0500, FAX

856-232-1754.

|