|

Polycarbonates

Polycarbonates offer high impact strength over a

wide temperature range. They can be supplied in

high heat, FDA, UV grades and glass filled. They

are available in a wide variety of stock shapes and can be

custom extruded into unlimited profiles. Following is an

overview of some of the polycarbonate materials offered

by fifteen leading suppliers.

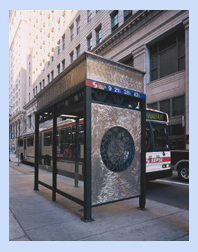

Tuffak® polycarbonate sheet from Atoglas of Atofina

Chemicals, Inc. suits applications requiring high impact

resistance.

Virtually unbreakable and resistant to vandalism,

Tuffak polycarbonate sheet is ideal for protecting decorative

graphics and advertisements

like those of an

urban bus shelter. Suitable

for a wide range of glazing

applications, Tuffak polycarbonate

sheet for transit

and school uses is available

with an abrasive-resistant

coating and solar tints.

Another sheet grade with

superior optical properties

serves in aircraft cockpits

and canopies.

Virtually unbreakable and resistant to vandalism,

Tuffak polycarbonate sheet is ideal for protecting decorative

graphics and advertisements

like those of an

urban bus shelter. Suitable

for a wide range of glazing

applications, Tuffak polycarbonate

sheet for transit

and school uses is available

with an abrasive-resistant

coating and solar tints.

Another sheet grade with

superior optical properties

serves in aircraft cockpits

and canopies.

Tuffak® S polycarbonate sheet for sign applications has

excellent toughness to withstand vandalism. UV-stabilized

and thermoformable, this sheet comes in various thicknesses

on reels or as sheet stock. Sign-grade sheet comes

in colorless, sign white and solar tints. Whiter Tuffak® XL

sign-white polycarbonate sheet combines the toughness

of polycarbonate sheet with an integrated UV light-resistant

barrier to improve weatherability and resist yellowing.

Additional grades of Tuffak polycarbonate sheet are formulated

specifically for food-grade applications and uses

requiring critical resistance to flammability.

For additional information, contact Tom DeMain,

Atoglas of Atofina Chemicals, Inc., 2000 Market Street,

Philadelphia, PA 19103, 215-419-7605, Fax: 215-419-

5512, Web: www.atoglas.com.

Makrofol® DPF-5072, a polycarbonate-based film with

a gloss first surface and a matte second surface, is specially

designed by Bayer Films Americas for bright

metallic look applications.

The gloss first surface provides the bright metallic look

and both the first and second surfaces are printable.

Makrofol

DPF-5072

is available

at a thickness

of

0.015” and

a width of

48.5”. It is

formable

using thermoforming, high-pressure forming, and hydroforming.

The material is ideal for flat appliques such as

backlit deadfront and film molding insert applications

with draw depths less than 0.5”. Typical applications

include automotive speedometer dials, PRNLs, cell phone

A and B covers and PDA A covers. It was designed for use

in the automotive, telecommunications and any other

industries that require formable metallic films.

The gloss first surface provides the bright metallic look

and both the first and second surfaces are printable.

Makrofol

DPF-5072

is available

at a thickness

of

0.015” and

a width of

48.5”. It is

formable

using thermoforming, high-pressure forming, and hydroforming.

The material is ideal for flat appliques such as

backlit deadfront and film molding insert applications

with draw depths less than 0.5”. Typical applications

include automotive speedometer dials, PRNLs, cell phone

A and B covers and PDA A covers. It was designed for use

in the automotive, telecommunications and any other

industries that require formable metallic films.

For additional information, contact D. J. Jantz, Bayer

Films Americas, 245 New Park Drive, Berlin, CT 06037,

866-659-9023, Fax: 877-229-3702.

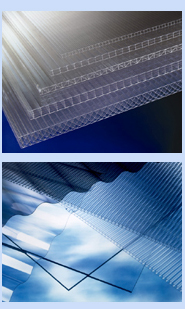

Brett Martin, one of the world’s leading polycarbonate

sheet manufacturers,

announced the formation of Brett Martin Inc. in the United States, set up to market

and supply the Marlon® range of polycarbonate sheet

across the country.

announced the formation of Brett Martin Inc. in the United States, set up to market

and supply the Marlon® range of polycarbonate sheet

across the country.

Marlon® ST Longlife

multiwall polycarbonate

is available in

a wide range of

structures and tints,

including dual tint

options. It is used

extensively in both

domestic and commercial

applcations

worldwide.

Marlon® CS Longlife

profiled polycarbonate

is a superb

material for all types

of rooflights, canopies

and greenhouses.

It has been used

on a number of high

profile stadia including

the City of Manchester stadium.

Brett Martin Inc. can also supply solid polycarbonate,

solid PVC, solid and profiled PVC and foam PVC.

For additional information, contact Ron Melvin, Brett

Martin Inc., P.O. Box 77342, Charlotte, NC 28271, 877-

874-4100, Fax: 704-752-8481, E-mail: usasales@

brettmartin.com, Web: www.brettmartin.com/usa.

Now it’s easier than ever before to rely on CO-EX for a

broad range of products including Macrolux® Multiwall

Polycarbonate Twin, Triple, 4, 5 and M-Wall sheet, heat

reflecting Macrolux® Athermic, RoofliteMB® for metal buildings

and Rooflite® Corrugated Polycarbonate sheet and

profiles.

CO-EX Corporation has been serving the horticultural,

architectural, metal buildings, plastics, signage and

home improvement markets since it was founded in 1988.

CO-EX Corporation has been serving the horticultural,

architectural, metal buildings, plastics, signage and

home improvement markets since it was founded in 1988.

CO-EX products feature the kind of advanced technology

and product development that you would expect from

an industry leader, with the type of superior service that comes from a

smaller, close-knit

operation.

Easy to install

and fabricate, Macrolux

and Rooflite

panels won’t crack

or split when cut or

drilled. The panels

can be readily cold formed to many bending radii and

can be fabricated on site to precise dimensions.

For additional information, contact Janice Pravorne,

CO-EX Corporation, 5 Alexander Drive, Wallingford, CT

06492, 800-888-5364 / 203-679-0500, Fax: 203-

679-0600, Web: www.co-excorp.com.

TECANAT® is Ensinger, Inc.’s line of polycarbonate

stock shape products.

It is available in rod and plate

stock, in diameters 0.25” to 8” and thicknesses that

range from 0.25” to 4” or more. TECANAT is also produced

in variety of thin wall tubing geometries.

Ensinger offers TECANAT in clear, black and with 20%

glass fiber reinforcement

as standard items.

It is available in rod and plate

stock, in diameters 0.25” to 8” and thicknesses that

range from 0.25” to 4” or more. TECANAT is also produced

in variety of thin wall tubing geometries.

Ensinger offers TECANAT in clear, black and with 20%

glass fiber reinforcement

as standard items.

TECANAT polycarbonate

has excellent toughness

and mechanical strength

and exhibits low water

absorption. TECANAT

has good insulative and

thermal properties, is

dimensionally stable,

weldable and bondable.

As a result, this product

is very machinable.

TECANAT can also be

polished to yield a transparent

appearance and

can be produced in a

variety of custom colors and additives. The resin is FDA

compliant and can be used in a range of applications

such as medical devices, food handling, machine guarding,

business machines and automotive components.

For additional information, contact Donna Mantia,

Ensinger, Inc., 365 Meadowlands Blvd., Washington,

PA 15301, 724-746-6050, Fax: 724-746-9209, E-mail:

dmantia@ensinger-ind.com, Web: www. ensinger-ind.com.

Futurplast manufactures clear polycarbonate tubes

ranging from 1/4” in diameter to 12” with 1/16”, 1/8”

and 1/4” wall thicknesses.

These products are stocked

at their strategically located distribution warehouses in

Montreal, Los Angeles, Chicago, Tampa and El Paso. If

you are looking for one 10” tube with a 1/4” wall and

need it overnighted to you. Futurplast has got it and will

get it to you when you need it.

These products are stocked

at their strategically located distribution warehouses in

Montreal, Los Angeles, Chicago, Tampa and El Paso. If

you are looking for one 10” tube with a 1/4” wall and

need it overnighted to you. Futurplast has got it and will

get it to you when you need it.

Futurplast is a distributor

committed a

one-stop shopping

destination for clear

polycarbonate tubes

as well as clear, colored

and frosted

“P95” acrylic products,

offering a large

selection of in-stock

rods and profiles.

Colored polycarbonate

tubes are also available on request.

For additional information, contact Joseph Sorella or

Lisa Houle, Futurplast Extrusions, 3435 Pitfield Blvd,

St-Laurent, QC, Canada, H4S 1H7, 888-812-9075,

Fax: 866-388-2955, E-mail: info@futurplast.ca, Web:

www.futurplast.ca.

Gallina USA LLC offers polycarbonate multiwall sheets

and systems.

They include arcoPlus 684 and arcoPlus

626 polycarbonate systems with battens. These materials

are translucent, light weight polycarbonate panels that

are easy to install, have an attractive appearance and are

very energy efficient and cost-effective to use.

They include arcoPlus 684 and arcoPlus

626 polycarbonate systems with battens. These materials

are translucent, light weight polycarbonate panels that

are easy to install, have an attractive appearance and are

very energy efficient and cost-effective to use.

Policarb 25mm

and 32mm (right)

are 7 layer polycarbonate

material

sheets that have a

high insulation factor

and strong

resistant to snow

and wind loads.

ArcoPlus Onda and arcoPlus 1000 are corrugated twin

wall Polycarbonate materials that have been used as office

dividers and for window and roofing applications where

natural light needs to be maximized.

ArcoPlus 323 (20mm) and arcoPlus 344 (40mm) are

“tongue and groove” system. These interlocking polycarbonate

sheets are used in manufacturing facilities as windows,

sunrooms, skylights etc.

For additional information, contact Betty Reed, Gallina

USA, LLC, 245 East Madison Ave. Milton, WI 53563,

888-825-4872 / 608-868-4253, Fax: 608-868-4253,

E-mail: betty@gallinausa.com, Web: www.gallinausa.com.

Green.tek, Inc. offers LEXAN® Thermoclear® Solar

Control multiwall sheets, providing extremely high solar reflection and an excellent Solar Factor (LT/ST).

The sheets

are available in 6’ widths, 8mm thickness and cut to length

up to 23’ long with Green.tek’s standard 10 year limited

warranty on yellowing, loss of light transmission and impact

strength. The combination of the Solar Control properties,

with the existing properties of LEXAN Thermoclear, makes

these sheets unique in the building and construction market.

The Solar Control coating selectively blocks IR light -

keeping your building, on average, 12° cooler than conventional

clear LTC/LTD glazed building.

The sheets

are available in 6’ widths, 8mm thickness and cut to length

up to 23’ long with Green.tek’s standard 10 year limited

warranty on yellowing, loss of light transmission and impact

strength. The combination of the Solar Control properties,

with the existing properties of LEXAN Thermoclear, makes

these sheets unique in the building and construction market.

The Solar Control coating selectively blocks IR light -

keeping your building, on average, 12° cooler than conventional

clear LTC/LTD glazed building.

Green.tek also recently added 2 UV 8mm LEXAN

Thermoclear Plus to its wide range of multiwall polycarbonate

products available at no minimums, cut to size and

shipped on time to meet job site deadlines. The product is

backed by a 10 year warranty against yellowing.

Thermoclear Plus offers UV protection on both sides, high

impact strength, excellent light transmission, outstanding

insulation properties, excellent weather properties, cold

curvability and is lightweight for ease of handling.

For additional information, contact Erin Huggett,

Green.tek, Inc., 407 North Main St., Edgerton, WI 53534,

800- 747-6440 / 608-884-9454, Fax: 608-884-9459, Email:

huggett@green-tek.com, Web: www.green-tek.com.

Hi-Tech Profiles, Inc., a leading manufacturer of

extruded stock shapes, has recently announced the addition

of polycarbonate to its offering of thermoplastic

materials available for custom quote.

HTP specializes in the extrusion of engineered thermoplastic

materials in sizes ranging from 0.050” to 3” OD.

They offer an extensive line of tubing, hollow rod and

bushing stock in nylon and acetal that is in stock and available

for immediate shipment, Custom sizes are quoted on

request with over twenty different materials to choose

from now including polycarbonate. Coiled tubing, custom

cutting and printing are available on request with standard

stock sizes available.

For additional information, contact Brian McGregor, Hi-

Tech Profiles, Inc., 185 South Broad Street, Pawcatuck, CT 06379, 800-342-5495, Fax: 860-599-0522, Web:

www.hitechprofiles.com.

Petro Extrusion Technologies, Inc. (PET, Inc.) is a

custom and stock tubing and profile extruder of engineering

grade thermoplastics.

They specialize in a wide range

of compounds including general purpose, UV, FDA and

high heat grades of polycarbonate.

They specialize in a wide range

of compounds including general purpose, UV, FDA and

high heat grades of polycarbonate.

PET, Inc. can custom

extrude clear

and colored polycarbonate

tubing

from 1/16” to 8” in

a variety of shapes

and wall thicknesses.

They also custom

extrude polycarbonate

profile

extrusions, offering an extensive selection of standard colors

with color matching capabilities.

For additional information, contact Sales, Petro

Extrusion Technologies, Inc., P. O. Box 99, Garwood, NJ

07027, 800-229-3338 / 908-789-3338, Fax: 908-789-

0434, E-mail: robert.petro@verizon.net, Web: www.

petroextrusions.com.

Plaskolite, Inc. offers

polycarbonate mirror sheet

in .118” and .236” thickness,

in a sheet size of 48” X

96”.  It can be easily fabricated,

saw, router or laser

cut. Polycarbonate mirror is

recommended for those

applications requiring high

impact strength, heat and

flame resistance.

It can be easily fabricated,

saw, router or laser

cut. Polycarbonate mirror is

recommended for those

applications requiring high

impact strength, heat and

flame resistance.

A scratch-resistant coating

is available for those

more demanding applications requiring abrasion, stain

and solvent resistance.

For additional information, contact Jonda Stover,

Plaskolite, Inc., P.O. Box 1497, Columbus, OH 43216,

800-848-9124, Fax: 877-538-0754, E-mail: plaskolite@

plaskolite.com, Web: www.plaskolite.com.

Quadrant Engineering Plastic Products offers

PC 1000 machine grade polycarbonate, a transparent

amorphous thermoplastic which offers very high impact

strength and high modulus of elasticity. The material

has a 290°F heat deflection temperature at 264 psi,

absorbs very little moisture and

resists acidic solutions. These properties,

in addition to good electrical

characteristics, make PC 1000 an

excellent choice for electrical/electronic

applications. Its strength,

impact resistance and transparency

also make it an ideal material for

certain transparent structural applications

such as sight glasses and

windows.

The material is stress-relieved, making

it ideal for close tolerance

machined parts. Stock shapes are produced

from polycarbonate resins

which meet the requirements of

ASTM D 3935.

A food grade polycarbonate that is

compliant with FDA, NSF, Canada AG

and USP Class VI regulations is available

on request. A glass fiber reinforced

polycarbonate grade is also

available on request.

For additional information, contact

Kress Schwartz, Quadrant Engineering

Plastic Products, 2120 Fairmont

Ave. P.O. Box 14235, Reading, PA

19612, 800-366-0310, Fax: 800-

366-0301, Web: www.quadrantepp.com,

E-mail: kress.schwartz@qplas.com.

Se-Kure Domes and Mirrors metalize polycarbonate

sheet stock for distribution. The sheet is currently stocked

in clear, gold and bronze, with other colors available on

request. Sheet sizes are 49” x 98” and 62” x 98” in thicknesses

of .06, .08, .98, .118, .177, .220 and .236 inches.

They also offer screen printing and laser cutting to size.

For additional information, contact Art Fox, Se-Kure

Domes and Mirrors, 1139 Haines Blvd. Sturgis, MI 49091,

800-253-2064 / 269-651-9351, Fax: 269-651-1467, Email:

afox@se-kure .com, Web: www.domesandmirrors.com.

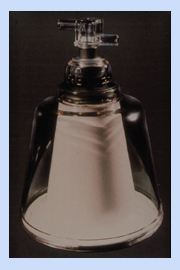

MAKROLON® WG (Window

Grade) polycarbonate

sheet is an amorphorus thermoplastic

made from

Bayer’s MAKROLON polycarbonate

resin. It is ideal

for use in a variety of applications,

ranging from containment

to fabricated parts.

This newly developed product

line of polycarbonate

sheet products extends the

thickness range offered by

Sheffield Plastics Inc.

This newly developed product

line of polycarbonate

sheet products extends the

thickness range offered by

Sheffield Plastics Inc. MAKROLON WG sheet ranges in

thickness from .750” thick up to 2” thick. Prior to the

introduction of MAKROLON WG, Sheffield manufactured

up to .500” thick polycarbonate sheet. Polycarbonate

sheet offers extremely high impact strength and high

modulus of elasticity. Typical applications include sight

windows for tanks/vessels, viewport windows, medical

parts and some military parts. The sheet features excellent

clarity, dimensional stability and good dielectric properties.

It offers excellent thermal performance and is fabrication

friendly.

MAKROLON WG demonstrates low levels of black

specks or other impurities and is UV stable. The superior

toughness of MAKROLON WG, combined with its clarity

and excellent dimensional stability, makes this the product

of choice in many demanding applications.

For additional information, contact D. J. Jantz, Sheffield

Plastics Inc., 119 Salisbury Road, Sheffield, MA 01257,

800-254-1707, Fax: 800-457-3553, Web: www.

sheffieldplastics.com.

Palsun Foamed Polycarbonate (PFP) sheets in a sine

wave configuration have been sold by Suntuf in the professional

builder’s market for over 3 years in the USA and Canada along with

accessories and fasteners

under the

Suntop® trademark.

Suntop panels,

(thermoformed PFP

sheets) manufactured

in three standard

colors, are

ideal for roofing and

cladding of industrial, agricultural and public out-buildings,

as well as DIY applications.

Suntop panels,

(thermoformed PFP

sheets) manufactured

in three standard

colors, are

ideal for roofing and

cladding of industrial, agricultural and public out-buildings,

as well as DIY applications.

Having a density and distributor cost of 25-30% below

traditional polycarbonate sheet, Palram’s PFP Sheet is

impact and weather resistant; has excellent thermal and

acoustical insulation properties; is lightweight, easy to

form and fabricate and has a service temperature range

equal to compact polycarbonate sheet.

Products featuring Palsun (PFP) in production and

development include: containers, casings, machinery protection,

kick panels, signs and guitars.

Suntuf, Inc. also manufactures polycarbonate and

polyvinyl chloride (PVC) panels for a wide variety of commercial

and industrial applications.

For additional information, contact Mike Howser,

Suntuf, Inc., 9735 Commerce Circle, Kutztown, PA

19530, 800-999-9459, Fax: 610-285-9928, E-mail:

suntuf@suntuf.com, Web: www.suntuf.com.

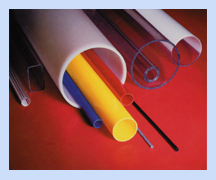

Sustaplast LP, a

leading manufacturer of

acetal, nylon and high performance

materials

announced the availability

of Sustanat® PC polycarbonate

machine

grade rods and sheets

are available from stock

in natural, black and

glass-filled 20%. Rods

range from 3/8” to 6”

diameter (10’ lengths)

and sheets 1/4” - 4”

(24” x 48”). Custom

sizes and cut-to-size pieces are also offered on request.

announced the availability

of Sustanat® PC polycarbonate

machine

grade rods and sheets

are available from stock

in natural, black and

glass-filled 20%. Rods

range from 3/8” to 6”

diameter (10’ lengths)

and sheets 1/4” - 4”

(24” x 48”). Custom

sizes and cut-to-size pieces are also offered on request.

For additional information, contact Chris Watras, SUSTAPLAST

L.P., 216 Philips Road, Exton, PA 19341, 800-

832-6787 / 484-875-9040, Fax: 484-875-9030, E-mail:

sustaman@sustaplast.com, Web: www.sustaplast.com.

|