|

Integrating Optimization, Inventory and Scrap Management

If there is one persistently frustrating aspect of cutting

plastic sheets, it is figuring out what to do with the

remnants. How do you decide what remnant size is

worth keeping? How do you organize your remnant inventory?

How in the world are you going to find these pieces

again when you need them?

remnants. How do you decide what remnant size is

worth keeping? How do you organize your remnant inventory?

How in the world are you going to find these pieces

again when you need them?

In the struggle to answer these questions another

important aspect of many cutting operations is often

ignored: optimization. Saving and logging remnant pieces

is a great way to improve your bottom line, but it is a “post

process” method of increasing efficiency and only works if

the remnants can be properly logged and recovered when

needed.

Optimization increases efficiency before the first sheet

is even cut. In its most basic form, an optimizer calculates

how to maximize material yield based on your raw material

sizes and your cut list parts. Most modern optimizers

also take advantage of machine parameters such as stack

(or book) height and can link to computerized CNC equipment.

Some can be set to optimize factors besides material

yield, such as material cost, machine operating time

and labor costs.

So which aspect deserves more

focus? Using an optimizer in its yield

mode increases yield and reduces

the number of remnants. That

means the remnants do not pile up

as quickly and there is more time to

effectively manage a smaller scrap

inventory, something the optimizer

can help you with as well.

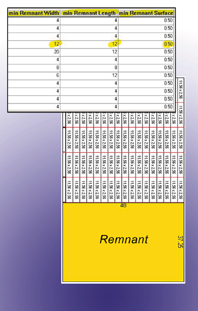

An optimizer with a scrap management

feature makes it very easy to

keep track of remnant inventory

because it can keep track of all part

list data throughout the entire manufacturing

process. You use the optimizer

to get the best fit for your

parts and the program will detect

remnants for you before you even

cut the first sheet. Recovering the

remnants can be done within the

same program using customizable

barcode labels. Since all the part data is in the optimization

software it is a snap to print a label for the remnants

and immediately add them to the available material or

put them in storage.

Another benefit of optimization and scrap management

with barcoding is that a well designed system

requires no manual data input. If you use an order entry

software or cut list software to generate your parts list

you will never have to type a thing into a spreadsheet.

The optimizer handles all of the information imported

from the order entry and can put any amount of that

information onto a label.

information onto a label.

Recovering the remnants can be done

with a barcode scanner, which immediately

returns all of the

information about a

remnant as soon

as the label is

scanned.

So how

does this

improve the

efficiency of a

shop? A lot of

companies

spend a lot of

time measuring

and logging

remnants

that

they will never use again because it is such a hassle to dig

them up. If you have software that is taking care of the

measurement beforehand and printing labels to help you

track down the remnants when you need them, you are

going to cut a lot of fat from your labor costs.

Using material in the most efficient way possible is a

goal for any shop trying to make a profit. Given the

lengths that most shops go through to squeeze the most

out of their raw material,

it is strange that so

many have ignored optimization.

It seems contradictory

that many see

optimizing as a waste of

money when they have

thousands of remnants

sitting around that can

be worth hundreds of

dollars each.

In reality inventory

management and optimization

are very closely

related. Remnants are

like any other raw material;

the difference is that

there is no immediate

use for the remnant

when you do the cutting.

when you do the cutting.

All of this makes sense when you consider that the remnant

is a natural result of the parts you have to cut and

the raw material sizes you have available, the core data

that the optimizer uses to make its calculations. It figures

out what material sizes will be left over before hand and a

simple calculation bridges the gap between waste piece

and re-usable part. When you consider this, combining the

two systems into one seems like a logical step and ultimately

may prove to be the surest cure for remnant

headaches.

Written by David E. Talbot, Product Manager for

Eurosoft, Inc., developers of the ARDIS Cutting Optimizer,

a sheet optimization program that produces high yield

combined with an enormous variety of customization

options such as reusable scrap. Eurosoft is actively

involved in integrating their Ardis software with existing

order entry and saw equipment. Their activities extend

from the individual plastic distributor with a single user

license to large network systems with integration to company

wide inventory control and order entry systems.

They offer training and a comprehensive technical support

service.

For more information, contact Eurosoft, Inc., 1628

Old Apex Road, Cary, NC 27513, 919-468-3003, Fax:

919-468-6374, E-mail: david@eurosoftinc.com, Web:

www.eurosoftinc.com.

|