|

Polishing and Bending See-Throughs

Acrylic sheet can be cut,

shaped, finished and

formed. How well and

how efficiently you handle these

basics will, in large part, determine

your success. We all know

our customers are more price

and quality conscious than ever

before.

Technology is rapidly increasing

efficiencies for plastic fabricators.

Yet with all the technological

gains, the basics remain

the same. You can cut more

pieces, with tighter tolerances,

faster than ever but you must

still finish the edges, peel

masking, bend and package.

Efficiency gains at the finishing

and bending operations will make you more competitive

and ultimately add to your bottom line. Ask yourself

the following:

-

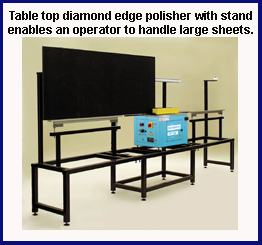

Does your equipment provide the versatility to handle

both large and small jobs with minimal setup time?

-

Does your bending equipment provide heat from both

above and below the work to reduce cycle times?

-

Does your edge finishing system polish and produce

matte finish bondable edges with the same piece of

equipment?

-

If you completed the last job in half the time, how would

that have affected your profit?

Automation

The majority of expenses

for any job relate to

the time it takes to complete

the job. Through

automation, efficiency

gains may be realized on

several fronts. Cost reductions,

productivity increases

and quality improvements

are three

that can have an immediate

and positive impact to

your bottom line. The following

outline shows several

areas for potential

profit improvements.

Efficiency Gains -

One operator can manage

multiple units

-

Current operator has time

for other tasks

Cost Reductions-

Delay and/or avoid additional

Hiring

-

Reduce current payroll levels

Productivity Increases-

Increased production speed

-

Operator fatigue no longer a

production factor

Reduced Lead Times for

Customers-

Can lead to ability to take on

additional business

-

Creates customer loyalty

Quality Improvements-

Scrap reduction

-

Manufacturing consistency

Capital investments in automation to reduce these costs

and or gain efficiency are usually based upon a 24 month or

less return on investment (ROI). Serious consideration should

be given to the acquisition of equipment and or process

improvements that fall within these criteria.

Setup/Tool Change Procedures

An often underestimated part of any production environment,

and one that when monitored and controlled can produce

efficiency gains and

add profit, is setup and tool

change procedures. Time

spent between job setups

and scheduled or unscheduled

tool changes adds up

quickly and associated

process costs become a

double edged sword. Not

only is your process in an

idle state at these times but

you are expending wage

resources during the downtime.

This must occur at

some point during the

process but the time duration

is certainly controllable.

quickly and associated

process costs become a

double edged sword. Not

only is your process in an

idle state at these times but

you are expending wage

resources during the downtime.

This must occur at

some point during the

process but the time duration

is certainly controllable.

Keep spare parts, tools and any necessary measuring instruments

as close to their relative machining process as possible.

The savings may not look like much in the short-term but

over time if you reduce set up and production times,

acquire versatile equipment, hire, train and empower good

people you will see a savings.

Consumable Tooling

Saving time and money here is a matter of watchful eyes.

Obviously a tool works best and produces superior quality

parts when

the tool is

new or just

sharpened.

All consumable

tools

have a fairly

finite life

expec tancy.

In most

instances

the wear

period is

predictable.

Once you

have established

the time pattern, remove the tool just before the failure

point. Removing the tool from service while it is still fairly

sharp will, in the long term, increase the life of the tool.

Less material from the tool itself will require removal to

bring the cutting edge back to optimum quality.

Different materials will cause your tooling, especially the

diamond tooling, to wear at varying time intervals. Harder

materials will result in longer tool life. Softer materials will

tend to roll over in a cutting process and gum up the edge of

a tool resulting in reduced tool life and inferior quality parts.

The manufacture of diamond polishing tools for plastics

is still mainly a human driven process. Much of the work is

completed by hand, so there will be some variation

between tools. The average life expectancy for the diamond

polishing tools is approximately 45-60 hours of use

between sharpenings and 8-10 sharpenings before the

inserts must be replaced.

Tool life for the diamonds is based upon working with

clear acrylic material. You will notice a better result with

cell cast materials over continuous cast or extruded materials.

Tool life will be reduced by one third to one half on

colored materials, especially smoke or black and on any of

the softer materials like impact modified, polycarbonates,

copolymers and PETG. Diamond tools have much the same

reaction as your saw and router tooling.

Another factor to consider in your production versus

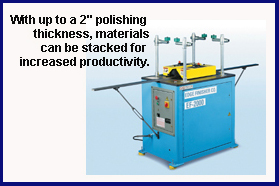

quality equation is to stack or not stack material.

Obviously machining multiple pieces of any material simultaneously

is preferable to machining them singly; however,

you will sacrifice some tool life and edge quality in the

process. The loss is due to the many layers of film and or

paper masking through which the diamond must pass.

Best results are obtained when machining no more than 5

pieces of 1/8” or 3/16” and no more than 4 pieces of 1/4”

material. Placing two smaller capacity machines into service

can improve both efficiency and quality of your finishing

operations. The smaller units will use less valuable floor

space and the same operator can easily manage both.

Bending Sheet Materials

After all of your efforts from initial design, cut to size and

finishing; you have a great deal of time and money invested

in each part. Now you must bend your creation to its

final form - this is the point in your process where you clearly

want error-free performance.

Enter the variables of ambient temperature fluctuation,

relative humidity, process variation and operator differences

and your bending operations can present quite the

challenge. Of the many options from calrod to quartz,

straight nichrome wire will provide the most heat consistency

over distance for your process.

Setups with nichrome wire range from over simplification

(a length of wire stretched between two ten-penny nails

driven into a two by four) to the extremely complex.

Generally, an 18-gauge wire set into a 15mm-20mm wide

aluminum reflector will provide the best results for materials

up to1/4” in thickness. Support along the underside and

pressure from above the material adjacent to the heating

area will reduce warping and bowing. One of the most

important and sometimes least attended to aspects of the

bending process is the cooling fixturing. Heating materials

in a desired location

is ten percent of the

battle. The remaining

effort is expended

designing, building

and adjusting

cooling jigs. Adding

insult to injury, time

and money is expended

constructing

a jig for a particular

job that may never

come around again. Consequently, the jig is either trashed

or thrown on a shelf to forever collect dust.

and adjusting

cooling jigs. Adding

insult to injury, time

and money is expended

constructing

a jig for a particular

job that may never

come around again. Consequently, the jig is either trashed

or thrown on a shelf to forever collect dust.

A universal jig that is designed to accommodate t-stands,

shoe risers, photo frames, sign holders and a litany of items

is ideal for increasing part quality. (Figure 2). Each new part

is placed into the jig, it moves the previous one forward

until the parts exit cooled and formed.

For optimum results and efficient cycle times, heat both

sides of the material simultaneously. If your current capability

allows heating from one side only, it is best to flip the

material over during the cycle to ensure even heat distribution

through the material.

Worth Mentioning

Bubble free polycarbonate bends: Heat from both sides,

lower the wire temperature and be patient! Always be sure

your material is fairly dry to prevent blistering.

Thin materials - .010 to .062 vinyl etc.: Use a Teflon®-

coated brass insert over the heating wire. You can then

place the material directly on the insert surface, heating a

narrow (1/16”) area of the material to produce sharp,

straight bends.

To reduce and/or eliminate the “dog ear” at the bend

point; block off the edges of your parts while they are over

the heating area. This will keep the edges a bit cooler than

the surface and, when bending the material, will tend to

flow toward the center and not out of the edge.

Adding Value

Customers need an education. Teach them about the different

processes you can use to ensure a part will look as

good on the hundredth day as it did on the first day. Yes, it

may cost a bit more but why should we feel the need to

apologize for pricing? Products of a superior quality do

cost a bit more and they are well worth the extra cost. You

know it, I know it, but do your customers know it?

Written by Edge Finisher Company, manufacturers and

suppliers of edge finishing, edge polishing and flame polishing

equipment and linear heat tables for plastics fabrication.

For more information, contact Edge Finisher

Company, 16 Stony Hill Road, Bethel, CT 06801, 800-625-5863, 203-796-7923, Fax: 203-796-7924, E-mail:

info.efc@blackstoneind.com, Web: www.edgefinisher.com.

|