|

Quality Assurance Criteria in Sheet and Pipe Fabrication

Thermoplastic sheet and pipe find expanding

and continuously more challenging

applications in a variety of markets and

demands for longevity and operational performance

of fabricated structures and components

vary greatly. The requirement for the

quality of a drip pan to catch the possible leak

of a washing machine is certainly very different

form a tank that holds aggressive chemicals at

elevated operating temperatures.

Thermoplastic sheet and pipe find expanding

and continuously more challenging

applications in a variety of markets and

demands for longevity and operational performance

of fabricated structures and components

vary greatly. The requirement for the

quality of a drip pan to catch the possible leak

of a washing machine is certainly very different

form a tank that holds aggressive chemicals at

elevated operating temperatures.

Companies can consider a number of approaches to

assure the quality of a fabricated structure. Let us take an

example in the fabrication of a structure that does not

require a high degree of operation performance. Some basic

steps can be good practices for a quality in construction.

When starting the fabrication, at least two materials are

involved that can come from different sources, sheet and

welding rod (and possibly piping or other connections).

After visual inspection it should always be verified that the

materials match each other, being able to trace the material

is an additional assurance. Very helpful here is any

documentation or other identifiers that state material

type, possibly date of manufacture and type of resin used,

unfortunately color is a poor indicator as numerous materials

are available in the same colors. A further good practice is to verify compatibility by laying down some hot air

welded beads and checking the penetration when trying to

pull off the welding rod. Should heated element contact

welding (butt welding) be involved in the project, the testing

of a sample weld will indicate that the welding parameters

(either stored in the memory of modern operating

controllers of sheet butt welding machines or available as

written guidelines) are adequate (Ref: DVS (German Welding

Society) technical code 2201-2; testing of semi-finished

products of thermoplastics: Weldability ďż˝ Test

Methods - Requirements). The execution of the work

should then be performed by qualified or certified welding

personnel whose ability to perform good welds should be

monitored. In some areas, the full documentation

of the welding and inspection process may be

worthwhile the effort for future reference.

With the limited testing processes available for

assuring the quality once the structure is completed,

companies use visual inspections (Ref: AWS

(American Welding Society) G1.10M:2001, Guide

for the Evaluation of Hot Gas, Hot Gas Extrusion

and Heated Tool Butt Thermoplastics Welds), possibly

high voltage spark testing of root welds or filling

the tank with fluid once completed to be reasonably

assured of a good construction.

The above are good steps to undertake for at lot

of applications but thermoplastic materials are

very often and increasingly used in processing systems

where a much greater degree of safety and

thus the assurance of quality is required. The cutting

out of a sample weld in a finished structure for

mechanical testing can only in very limited circumstances

be the method of choice as now reconstruction/

repairs have to be performed which in all

likelihood rather decrease than increase operational

performance. Thus the industry has the need

for welding procedure and performance qualification

verification.

An excellent tool for engineers, inspectors, end

users or other parties involved in the design and

construction of a system involving thermoplastic

pipe and sheet is AWS B2:4 �Specification for

Welding Procedure and Performance Qualification

for Thermoplasticsďż˝. This document references

industry wide used welding procedures, materials,

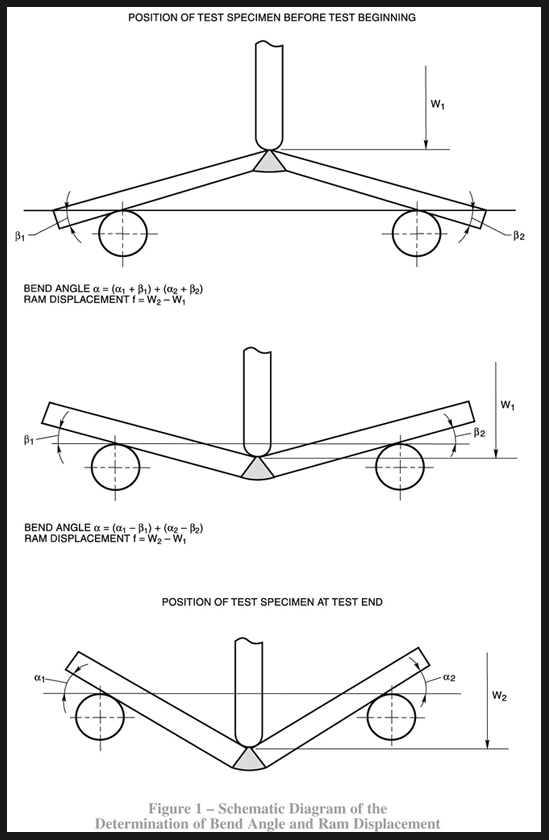

testing methods and qualification variables. Figure

1 for example shows the angle and ram displacement

of the bend test.

This is a short overview describing the kind of

considerations and procedures that are being utilized

to provide for confidence within the engineering

and end using community to choose thermoplastic

constructions. Companies may certainly use

additional or other procedures pertaining to their

field. Not considered here are topics related to systems/

tank design and the short and long term performance

to individual materials related to their

application.

Written by Dagmar Ziegler, Vice President, Sales,

WEGENER Welding, LLC, distributors of thermoplastic

welding and fabrication equipment including hand welding

systems, extrusion welding systems, sheet bending and

fusion machines, pipe butt and socket fusion tools and

equipment, pipe band saws, AC and DC spark testers and

a wide variety of specialty welding equipment.

For more information, contact WEGENER Welding,

LLC, 16W231 S. Frontage Road, Suite 12, Burr Ridge, IL

60527, 630-789-0990, Fax: 630-789-1380, E-mail: info@wegenerwelding.com, Web: www.wegnerwelding.com.

|