|

Matching Material Matters

When welding

thermoplastics,

one of the

key components is the

material itself. For as

long as plastic welding

has been around many

people do not understand

the basics. Webster�s Dictionary definition of welding:

to unite (surfaces) by softening them with heat.

When welding

thermoplastics,

one of the

key components is the

material itself. For as

long as plastic welding

has been around many

people do not understand

the basics. Webster�s Dictionary definition of welding:

to unite (surfaces) by softening them with heat.

The number one rule of welding thermoplastics is you

must weld like-plastic-to-like-plastic. In order to get a

strong, consistent

weld it is necessary

to make sure your

substrate and your

welding rod are

identical: for instance,

Polypropylene to

Polypropylene,

Polyurethane to

Polyurethane,

Polyethylene to

Polyethylene, etc.

Polypropylene is

one of the easiest

plastics to weld

and is used for many different applications. PP has

excellent chemical resistance, low specific gravity, high

tensile strength and is the most dimensionally stable

polyolefin. Proven applications using PP are plating

equipment, tanks, ductwork, etchers, fume hoods and

scrubbers, and orthopedic. In order to weld PP the welder

needs to be

at approximately

572�F:

determining

your temperature

will

depend on

which welder

you purchase.

Using a hot

air thermoplastic

welder

(Fig. 1) with a 500 watt 120 volt heating element, the

air regulator should be set at approximately 5 p.s.i. and

the rheostat at 5.

By doing this you should be in the

vicinity of 572�F.

By doing this you should be in the

vicinity of 572�F.

Another fairly easy

plastic to weld is

Polyethylene. The most

important rule about

welding Polyethylene is

that you can weld low to

high but not high to low.

Meaning, you can weld

Low Density Polyethylene welding rod to High Density

Polyethylene sheet but not vice versa. The reason being is

quite simple: the higher the density, the more difficult it

is to break down the components to weld. If the components

cannot be broken down at the same rate then they

cannot join together properly. Other than making sure

your densities are compatible. Polyethylene is a pretty

easy plastic to weld. Polyethylene is impact resistant, has

exceptional abrasion resistance, high tensile strength, is

machinable and has low water absorption. Proven applications

for PE are bins and liners, tanks, laboratory vessels,

cutting boards and slides. To weld LDPE you need to

have approximately 518�F, regulator set at approximately

5 ďż˝ to 5 ďż˝ and the rheostat at 5. Like PP, HDPE

is weldable at 572�F.

PVC, Polyvinyl Chloride, is a plastic that can be

extremely temperamental, however, it is an extremely

useful material. PVC has excellent resistance to corrosion,

weather and impact, is an excellent thermal and

electrical insulator and is self-extinguishing. Proven applications

for PVC are plating equipment, tanks and liners,

ductwork, etchers, fume hoods and scrubbers. When

welding PVC, if you have your temperature too high the

material will char, if it is too low it will not weld. Because

of the chloride in the material it is necessary to break it

down. To do this you need to score the surface area you

want to weld and then

using a thinner such

as MEK, Methyl Ethyl

Keytone, to clean the

surface.

electrical insulator and is self-extinguishing. Proven applications

for PVC are plating equipment, tanks and liners,

ductwork, etchers, fume hoods and scrubbers. When

welding PVC, if you have your temperature too high the

material will char, if it is too low it will not weld. Because

of the chloride in the material it is necessary to break it

down. To do this you need to score the surface area you

want to weld and then

using a thinner such

as MEK, Methyl Ethyl

Keytone, to clean the

surface.

Again, like PP

and HDPE, PVC needs

572�F to weld. As a

side note, PVC is the

exception to the like-plastic-

to-like-plastic

rule. It is possible to

weld PVC to acrylic

and vice versa.

Again, like PP

and HDPE, PVC needs

572�F to weld. As a

side note, PVC is the

exception to the like-plastic-

to-like-plastic

rule. It is possible to

weld PVC to acrylic

and vice versa.

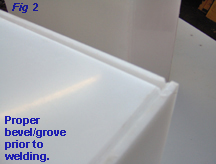

Prior to welding

thermoplastics, there are a few simple steps that need

to be taken to ensure a proper weld. Clean all surfaces, including the welding rod,

with MEK or a similar solvent.

Groove the substrate

large enough to accept the

welding rod (Fig. 2) and cut

the end of welding rod to a

45ďż˝ angle. Once the welder

has come to temperature,

you need to prep the substrate

and the welding rod.

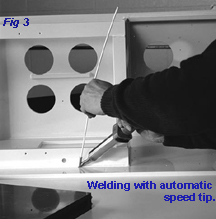

By using an automatic

speed tip (Fig. 3) a lot of

the prep work is done for

you. Holding the welder

about an inch above the

substrate, insert the welding

rod in the tip and move it in an up and down motion

three to four times. Doing this will heat the welding rod

while heating the substrate. An indication the substrate

is ready to be welded is when it starts getting a fogging

effect�similar to blowing on a piece of glass. Using firm

and consistent pressure, push down on the boot of the

tip. The boot will push the welding rod into the substrate.

If you choose to, once the welding rod adheres to

the substrate you can let go of the rod and it will automatically

pull itself through.

Most thermoplastics are sandable and the strength of

the weld will not be affected when

sanded. Using 60 grit sandpaper,

sand off the top part of the welding

bead, then work your way up

to 360 grit wet sandpaper to get a

clean finish. When working with

Polypropylene or Polyethylene it is

possible to regain their glossy surface

by lightly heating the surface

with a yellow open flame propane

torch Normal Fire Safety procedures

should be followed. Once

these steps are completed, you

should have a weld that looks similar

to the photo (Fig. 4).

Keeping the above tips in mind,

welding thermoplastics can be a fairly easy process to

learn. For other procedures and standards, contact your

local distributor.

Written by Paige D. Bowen, Marketing Director for

Seelye, Inc., manufacturers of a full line of hot air/gas

welders.

For more information, contact Seelye, Inc., 333C

Enterprise Street, Ocoee, FL 34761, 800-258-2936/407-656-6677, Fax: 407-656-5244, E-mail: seelyeinc@aol.com, Web: www.seelyeinc-orl.com.

|