|

Polyolefins Spotlight

Polyethylene (PE) and Polypropylene (PP) are two of

the largest volume thermoplastics used today and are

available in a wide range of grades and formulations. PE

is commonly grouped into Low, Medium and High density

formulations’ and PP is available in homopolymer and

copolymer formulations. The various formulations of

these popular polyolefins impart a wide range of properties

making them appropriate for countless applications.

Generally speaking, polyolefins are tough, chemical

resistant and offer good electrical properties with a

low coefficient of friction and moisture absorption. They

are relatively lightweight and easy to fabricate.

Polyolefins find proven applications in a wide range of

markets from medical and chemical to toys and sporting

goods and oil and gas to food processing and marine.

Following is an overview of a variety of materials from

sheet, rod and tube to massive shapes and profiles.

Close Tolerance Rod

Artek offers rod dowelling services to provide close tolerance

Duravar® rod stock with excellent concentricity to

meet the needs of today’s critical machine and job shop

operations.

Artek is a leading supplier of UHMW rod stock to the

plastic distribution market place. Their full line of extruded

UHMW-PE rod is offered in diameters from 1/4" up

through 10" in virgin, reprocessed and enhanced formulations.

Artek provides a large range of standard diameters,

dowelled to close tolerance, ranging from 1" up through 3"

diameter. In addition they will quote custom dowelled

diameters upon request.

Their dowelling system provides excellent diameter concentricity

with tolerances as close as +/- .003" to help

improve secondary machining processes.

Their dowelling system provides excellent diameter concentricity

with tolerances as close as +/- .003" to help

improve secondary machining processes.

The rod is available in a variety of standard and custom

colors that meet FDA and USDA requirements. Artek can

also color match to meet the needs of the project.

In addition to the traditional 5' and l0' industry standard

lengths, Artek can provide up to 20' lengths.

Full Sheet Stock

Artek also

introduced the

newest member

of the Duravar

UHMW-PE

family of

extruded and

skived full sheet

as a standard

product line.

Artek’s in-line stress relieving process reduces stress,

improves productivity and minimizes waste when cutting

this prime material into blocks or strips. The sheet has

excellent surface finish and thickness consistency. Sheet

sizes are 48" x 96" and 48" x 120"– in thickness from

1/8” up to 2".

For additional information, contact Randall Kirkpatrick,

Artek, Inc., 3311 Enterprise Road, Fort Wayne, IN 46808,

800-762-6808, Fax: 260-484-6914, Web: www.artek-inc.com.

UHMW-PE High Bond Tape

CS Hyde’s new tape has all

the benefits of

strong, slippery,

abrasion-resistant

UHMW-PE tape,

plus a super-high

bond adhesive.

UHMW High Bond

is an excellent

choice for difficult to-

bond, low

surface energy

surfaces such as plastic, powder-coated, foam, oily metals

or slightly textured materials. UHMW-HB even sticks to

high slip surfaces: Teflon®, Acrylic, PE, Glass, etc.

CS Hyde’s new tape has all

the benefits of

strong, slippery,

abrasion-resistant

UHMW-PE tape,

plus a super-high

bond adhesive.

UHMW High Bond

is an excellent

choice for difficult to-

bond, low

surface energy

surfaces such as plastic, powder-coated, foam, oily metals

or slightly textured materials. UHMW-HB even sticks to

high slip surfaces: Teflon®, Acrylic, PE, Glass, etc.

Bond strength of this product increases with time and

temperature. High humidity has minimal effect. UHMWHB

is also water and chemical resistant. UHMW substrate

is FDA and USDA approved.

UHMW thickness ranges from .005" to .060". The adhesive

is .002” thick: black semi-conductive, anti-static product

is also available. Widths range from .5" up to 24". It is

sold in rolls, sheets, continuous footage and custom diecut

shapes.

For additional information, contact Tiffany Hoerle, CS

Hyde Company, 1351 N. Milwaukee Ave., Lake Villa, IL

60046, 847-395-0325, Fax: 847-395-0334, E-mail:

sales@cshyde.com, Web: www.cshyde.com.

30% GF Polypropylene

GEHR Plastics offers

GEHR Polypropylene,

which demonstrates a

high mechanical and

tensile strength and is

coupled with great

impact strength. GEHR

Polypropylene resists

stress cracking and is

easy to weld. Chemical

and electrical properties

are excellent and operating temperatures range

between 41°F to 210°F. Characteristics include low density,

low moisture absorption, good heat resistance, high chemical resistance, high tensile strength, high surface strength but low abrasion resistance. Natural is copolymer

resin and colored is homopolymer.

GEHR Plastics offers

GEHR Polypropylene,

which demonstrates a

high mechanical and

tensile strength and is

coupled with great

impact strength. GEHR

Polypropylene resists

stress cracking and is

easy to weld. Chemical

and electrical properties

are excellent and operating temperatures range

between 41°F to 210°F. Characteristics include low density,

low moisture absorption, good heat resistance, high chemical resistance, high tensile strength, high surface strength but low abrasion resistance. Natural is copolymer

resin and colored is homopolymer.

GEHR also offers GEHR HiPro® 30% glass reinforced

polypropylene. This material maintains the excellent

chemical and corrosion resistance of unfilled PP with

added superior dimensional stability (CLTE = 3.0 x 10-5

in/in/°F), higher surface stiffness, higher temperature

resistance with a Heat Deflection Temperature of +311°F

and much better compressive strength.

The color is black and is targeted for higher temperature

chemical applications where cost is an issue.

For additional information, contact Bill Shields, GEHR

Plastics USA, 24 Creek Circle, Boothwyn, PA 19061, 800-PVC-GEHR/610-497-8941, Fax: 610-497-8901, E-mail: info@gehrplastics.com, Web: www.gehrplastics.com.

Improved Medical Grade

Polypropylene Line

Ensinger, Inc. has set the standard for quality and innovation

with their line of products developed specifically for

medical applications. Tops among them is the TECAPRO™

MT line, a

polypropylene

based

product with

exceptionally

low residual

stress characteristics

that facilitate

the fabrication

of

dimensionally stable parts consisting of varying cross sections.

The material can withstand repeated hot steam

sterilization procedures without deforming and has a high

resistance to detergents and disinfectants. This has historically

made it an excellent material choice for surgical

caddies and instrument handles.

Ensinger, Inc. has set the standard for quality and innovation

with their line of products developed specifically for

medical applications. Tops among them is the TECAPRO™

MT line, a

polypropylene

based

product with

exceptionally

low residual

stress characteristics

that facilitate

the fabrication

of

dimensionally stable parts consisting of varying cross sections.

The material can withstand repeated hot steam

sterilization procedures without deforming and has a high

resistance to detergents and disinfectants. This has historically

made it an excellent material choice for surgical

caddies and instrument handles.

Until now however, users

who wanted to design parts in colors other than white had

little choice because of those colors’ inability to receive

laser etched markings of significant contrast to render the

markings readable. Ensinger has now developed a black

TECAPRO MT that contains an additive that enhances the

material’s ability to receive laser etching. Markings laser

etched into this new black material are so clear, they appear to be silk-screened. Engineers and designers alike will

be drawn to this material for its versatility, and its stability.

For additional information, contact Bruce Dickinson,

Ensinger, Inc., 365 Meadowlands Blvd., Washington, PA

15301, 856-227-0500, Fax: 724-746-9209, E-mail: sales@ensinger-ind.com, Web: www.ensinger-online.com.

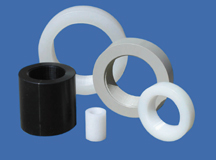

Stock Tank Couplings

Fabricated and molded tank manufacturers are finding

there is no longer a need for trips to a machine shop

because economical heavy-duty tank couplings, designed

for their application,

are now

available. IPW

tank couplings

are easy to

install and are

sized to fit standard

hole saw

dimensions.

They have a

shoulder that

gauges installation

depth and provides for guaranteed square installations

on flat surfaces. The shoulder also provides better

weld strength and easy installation on round tanks. The

shoulder and the low profile design, combined with thick

cross sections, practically eliminate couplings shearing off

from side impact. The thick cross-sections prevent the

splitting commonly seen with FPT threaded couplings.

IPW features sizes 1/2" through 4" from stock in natural

HDPE, black HDPE, natural PP and black Type II (copolymer)

PP. Eurogray PP, PVDF, PVC and CPVC materials and

sizes 1/8" to 24" are now available on request. IPW provides

full couplings when interior piping is needed and for

vertical installations on domed tanks.

Fabricated and molded tank manufacturers are finding

there is no longer a need for trips to a machine shop

because economical heavy-duty tank couplings, designed

for their application,

are now

available. IPW

tank couplings

are easy to

install and are

sized to fit standard

hole saw

dimensions.

They have a

shoulder that

gauges installation

depth and provides for guaranteed square installations

on flat surfaces. The shoulder also provides better

weld strength and easy installation on round tanks. The

shoulder and the low profile design, combined with thick

cross sections, practically eliminate couplings shearing off

from side impact. The thick cross-sections prevent the

splitting commonly seen with FPT threaded couplings.

IPW features sizes 1/2" through 4" from stock in natural

HDPE, black HDPE, natural PP and black Type II (copolymer)

PP. Eurogray PP, PVDF, PVC and CPVC materials and

sizes 1/8" to 24" are now available on request. IPW provides

full couplings when interior piping is needed and for

vertical installations on domed tanks.

For additional information, contact Phil Holt, Industrial

Plastic Works, 6220 Enterprise Drive, Knoxville, TN

37909, 800-966-1450, Fax: 865-637-4540, E-mail:

sales@ipw.us.com, Web: www.ipw.us.com.

Boosting Sales Through

Innovation

Every plastics distributor and fabricator knows innovation

is the key to growth. Sometimes a new product simply provides

an “excuse” to reach out to an old contact. But

sometimes a new product can open up entire categories of

prospects and lucrative new business opportunities. King

MicroShield® by King Plastic Corporation is just such an

innovation.

King MicroShield is a new kind of anti-microbial now

available in many of King Plastic’s sheet products for medical,

laboratory and

institutional applications.

It helps products

stay cleaner between

cleanings and inhibits

the growth of productdamaging

microorganisms,

including bacteria,

algae and fungi on

the surface. Microbe

cell walls that come

into contact with the

material are physically

destroyed on contact,

without creating opportunities

for adaptive or

resistant strains to

form. It is bonded at the atomic level throughout the

sheet, so it retains its effectiveness for the life of the product

and will not leach out and harm the environment.

Every plastics distributor and fabricator knows innovation

is the key to growth. Sometimes a new product simply provides

an “excuse” to reach out to an old contact. But

sometimes a new product can open up entire categories of

prospects and lucrative new business opportunities. King

MicroShield® by King Plastic Corporation is just such an

innovation.

King MicroShield is a new kind of anti-microbial now

available in many of King Plastic’s sheet products for medical,

laboratory and

institutional applications.

It helps products

stay cleaner between

cleanings and inhibits

the growth of productdamaging

microorganisms,

including bacteria,

algae and fungi on

the surface. Microbe

cell walls that come

into contact with the

material are physically

destroyed on contact,

without creating opportunities

for adaptive or

resistant strains to

form. It is bonded at the atomic level throughout the

sheet, so it retains its effectiveness for the life of the product

and will not leach out and harm the environment.

King Plastic Corporation has a history of innovation

spanning more than four decades. The North Port,

Florida-based company manufactures dozens of varieties

of polymer sheets, slabs and massive shapes used in a

broad range of applications. These include waterproof

cabinetry and casegoods (commercial and residential),

restroom partitions, pipe-grade and chemical-resistant

fabrications, cutting boards, signage, neutron shielding

and, of course, boat parts.

For additional information, contact Lou Stegner, King

Plastic Corporation, 1100 N. Toledo Blade Blvd., North

Port, Florida 34288, 941-493-5502, Fax: 941-497-3274, E-mail: sales@kingplastic.com, Web: www.kingplastic.com.

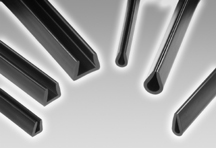

PE Channels

Petro Extrusion Technologies Inc., (PET Inc.) specializes in

engineering grade thermoplastics as well as custom and

stock products in

low, linear low,

medium and highdensity

polyethylene.

PET, Inc. carries

a stock line of

6 different PE

channel shapes.

The stock channels

can also be

made-to order in any desired cut lengths.

PET Inc., also produces an endless variety of custom

shapes and tube sizes ranging from 1/32” diameter up to

6” diameter. Petro has custom co-extrusion capability and

can extrude in any combination of compatible PE materials

or colors as your requirement dictates. They specialize in neon and specialty custom colors, as

well as all standard colors.

Petro Extrusion Technologies Inc., (PET Inc.) specializes in

engineering grade thermoplastics as well as custom and

stock products in

low, linear low,

medium and highdensity

polyethylene.

PET, Inc. carries

a stock line of

6 different PE

channel shapes.

The stock channels

can also be

made-to order in any desired cut lengths.

PET Inc., also produces an endless variety of custom

shapes and tube sizes ranging from 1/32” diameter up to

6” diameter. Petro has custom co-extrusion capability and

can extrude in any combination of compatible PE materials

or colors as your requirement dictates. They specialize in neon and specialty custom colors, as

well as all standard colors.

For additional information, contact Robert Petrozziello,

Petro Extrusion Technologies, Inc., P. O. Box 99, 490

South Ave., Garwood, NJ 07027, 800-229-3338/908-789-3338, Fax: 908-789-0434, E-mail: rpetro@petroextrusion.com, Web: www.petroextrusion.com.

Hex Rod

Plastic Products, Inc. (P.P.I.)

offers hexagonal rod

machined to close tolerance

(+/-.005”) starting at sizes

of 3/8” across the flats.

Hex rod is available from

engineered materials including

Nylon, Delrin®, UHMW,

Polypropylene, Polysulfone,

P.E.E.K., Noryl®, Ultem®,

Teflon® and many more.

Plastic Products, Inc. (P.P.I.)

offers hexagonal rod

machined to close tolerance

(+/-.005”) starting at sizes

of 3/8” across the flats.

Hex rod is available from

engineered materials including

Nylon, Delrin®, UHMW,

Polypropylene, Polysulfone,

P.E.E.K., Noryl®, Ultem®,

Teflon® and many more.

P.P.I. can supply hex rod in

lengths of 5, 8 or 10 foot. Other lengths can be quoted

upon request.

P.P.I. is also one of the largest stocking distributors of

plastic rod on the east coast and can supply rod in a large

variety of materials cut to any length.

For additional information, contact David Windt, Plastic

Products, Inc., P.O. Box 188, Bessemer City, NC 28016,

800-752-7770/704-739-7463, Fax: 704-739-5566,

E-mail: dwindt@plastic-products.com, Web: www.plasticproducts.com or www.HexRod.com.

PP Stock

Shapes

Plastifab Industries offers a comprehensive

product line of standard

stock shapes in Low Density, High

Density and Polypropylene commonly

known as polyolefins.

Plastifab Industries offers a comprehensive

product line of standard

stock shapes in Low Density, High

Density and Polypropylene commonly

known as polyolefins.

Polyolefins find proven applications

in markets such as medical,

chemical, toys, sporting goods, oil

and gas and food processing. LDPE,

HDPE and polypropylene rods are

available in sizes ranging from 1/8”

to 16” diameter in natural and

black. Polyolefin heavy wall tubular

bar is offered with a minimum ID of

2” through and OD of 22”.

Semi-rigid polyolefin tubing is a

mainstay in oil, hydraulic fluid,

water and beverage transfer, oil

and gas and is

available in

Diameters as

small as .170"

inside in natural

and a wide

selection of

colors.

Welding rods

are available in

LDPE, HDPE

and polypropylene and are used in conjunction with sheet

and plate to fabricate tanks, tank liners and boxes for corrosive

environments. Polyolefin standard stock shapes are

typically manufactured from FDA-approved resins and

meet USDA, NSF and Canadian Department of Agri cul -

tural requirements for direct food contact.

For additional information, contact Plastifab Industries,

7777 Transcanadienne, Saint Laurent, Quebec, H4S 1L3,

Canada, 800-361-4774/514-325-9840, Fax: 514-325-5222,

E-mail: infoprod@plastifab.ca, Web: www.plastifab.ca.

Multi Wall PP Sheet

Polygal offers a unique 8mm polypropylene sheet for the

building materials and commercial greenhouse markets.

The sheet, designed for use as side and end walls in the

greenhouse market, can also be specified and installed for

interior applications in the architectural market where privacy

and/or back lighting is desired. The new 8mm

polypropylene sheet by Polygal is UV protected through the

entire sheet, not just co-extruded on one or two surfaces.

Polygal offers a unique 8mm polypropylene sheet for the

building materials and commercial greenhouse markets.

The sheet, designed for use as side and end walls in the

greenhouse market, can also be specified and installed for

interior applications in the architectural market where privacy

and/or back lighting is desired. The new 8mm

polypropylene sheet by Polygal is UV protected through the

entire sheet, not just co-extruded on one or two surfaces.

For additional

information,

contact

Nick Koszegi,

Polygal, Inc.,

P. O. Box

410592,

Charlotte,

NC 28241,

800-527-0095, Fax: 704-588-7400, E-mail sales@polygal.com,

Web: www.polygal.com.

Detectable Plastic for

Food Processing

Röchling Engineering Plastics

now offers a ground breaking

solution to the ever present

risk of contamination of food

during its processing and production:

Polystone® M MDT.

This sophisticated engineering

plastic caters to the food processing

industry and enables

food processors to detect contamination

early and therefore

avoid significant potential

financial losses. The unique additives in this product allow

it to be easily traced by standard metal detectors while

continuing to provide the outstanding wear-resistance and

sliding properties you would expect from Polystone M

(UHMW-PE). Designed to replace machined parts made

from steel and lower performing plastics, this engineering

polymer has high-impact strength, is easily machined and

has no moisture absorption. Polystone® M MDT complies

with FDA regulations concerning direct contact with food.

Every food processor that utilizes metal detectors in their

processing or packaging operations can easily realize the

advantages of Polystone M MDT.

Röchling Engineering Plastics

now offers a ground breaking

solution to the ever present

risk of contamination of food

during its processing and production:

Polystone® M MDT.

This sophisticated engineering

plastic caters to the food processing

industry and enables

food processors to detect contamination

early and therefore

avoid significant potential

financial losses. The unique additives in this product allow

it to be easily traced by standard metal detectors while

continuing to provide the outstanding wear-resistance and

sliding properties you would expect from Polystone M

(UHMW-PE). Designed to replace machined parts made

from steel and lower performing plastics, this engineering

polymer has high-impact strength, is easily machined and

has no moisture absorption. Polystone® M MDT complies

with FDA regulations concerning direct contact with food.

Every food processor that utilizes metal detectors in their

processing or packaging operations can easily realize the

advantages of Polystone M MDT.

For additional information, contact Birgit Moecks,

Röchling Engineered Plastics, P.O. Box 2729, Gastonia,

NC 28053, 704-922-7814, Fax: 704-922-1835, E-mail:

info@roechling-plastics.us, Web: www.roechling-plastics.us.

Increased Production &

Stock

SIMONA increases production, stocking and service capability

at new Hazleton plant.

At the new location, SIMONA AMERICA has expanded

its stocking programs in HDPE and copolymer polypropylene

to service markets like pipe grade, orthotics and

prosthetics, chemical/corrosions resistance and general

industrial products. In addition to these increased stock

levels in sheet, SIMONA tripled its inventory of PVC and

polyolefin rod stock with rod diameters ranging from 1/4”

to 32”. “Being responsive to growing customer needs

according to John

Ploskonka,

Executive Vice

President of Sales

and Marketing,

“is the cornerstone

for our customers’

success

and ultimately

our success.”

John adds,

“Delivering quality

products and

service requires

ongoing investment

and focus and SIMONA AMERICA made that commitment

to our customer success through the investment

in the plant. A private rail siding capable of holding over

one million pounds of product was completed in 2008.

Having the ability to hedge against this year’s escalating

resin allowed us to provide real savings to our customers.

We see our flexibility as strength in meeting changing customer

schedules and requirements.”

SIMONA increases production, stocking and service capability

at new Hazleton plant.

At the new location, SIMONA AMERICA has expanded

its stocking programs in HDPE and copolymer polypropylene

to service markets like pipe grade, orthotics and

prosthetics, chemical/corrosions resistance and general

industrial products. In addition to these increased stock

levels in sheet, SIMONA tripled its inventory of PVC and

polyolefin rod stock with rod diameters ranging from 1/4”

to 32”. “Being responsive to growing customer needs

according to John

Ploskonka,

Executive Vice

President of Sales

and Marketing,

“is the cornerstone

for our customers’

success

and ultimately

our success.”

John adds,

“Delivering quality

products and

service requires

ongoing investment

and focus and SIMONA AMERICA made that commitment

to our customer success through the investment

in the plant. A private rail siding capable of holding over

one million pounds of product was completed in 2008.

Having the ability to hedge against this year’s escalating

resin allowed us to provide real savings to our customers.

We see our flexibility as strength in meeting changing customer

schedules and requirements.”

For additional information, contact John Ploskonka,

SIMONA AMERICA Inc., 64 N. Conahan Drive, Hazleton

PA 18201, 866-501-2992, Fax: 800-522-4857, E-mail:

mail@simona-america.com, Web: www.simona-america.com.

Polyolefin Website Directory

|

Artek, Inc. | www.artek-inc.com |

| CS Hyde Company | www.cshyde.com |

| GEHR Plastics USA | www.gehrplastics.com |

| Ensinger, Inc. | www.ensinger-online.com |

| Industrial Plastic Works | www.ipw.us.com |

| King Plastic Corporation | www.kingplastic.com |

| Petro Extrusion Technologies, Inc | www.petroextrusion.com |

Plastic Products, Inc. | www.plastic-products.com//www.hexrod.com

|

| Plastifab Industries | www.plastifab.ca

|

| Polygal, Inc. | www.polygal.com |

| Röchling Engineered Plastics | www.roechling-plastics.us |

| SIMONA AMERICA Inc. | www.simona-america.com |

|