|

Innovations in Plastic Acrylic Sheet Casting

Satisfying the need for

specialty materials in

an age of supply

constraints

As more plastic manufacturers

are streamlining operations

and shifting acrylic

sheet casting to overseas production,

it becomes very difficult to

offer innovative specialty materials.

Larger required material

runs, longer lead times, expensive

shipping costs – how do

architects and designers using acrylic in architectural

applications satisfy their desire for specialty materials

under these circumstances? There are fewer and fewer

opportunities left for innovation in the local marketplace

because these supply issues have become a real stumbling

block.

As more plastic manufacturers

are streamlining operations

and shifting acrylic

sheet casting to overseas production,

it becomes very difficult to

offer innovative specialty materials.

Larger required material

runs, longer lead times, expensive

shipping costs – how do

architects and designers using acrylic in architectural

applications satisfy their desire for specialty materials

under these circumstances? There are fewer and fewer

opportunities left for innovation in the local marketplace

because these supply issues have become a real stumbling

block.

In the cell cast acrylic sheet market, larger manufacturers

are simply not set up to do individualized, small volume

custom projects that require mixing colors entirely by

hand, rather than using large automated equipment.

Many companies abound that can produce a large volume

economy product, but

those looking for innovative

or customized

approaches are finding

it difficult to come by.

There is a demand for

specialty materials,

but the demand is not

consistent. Everything

is project-specific –

one customer may love

a particular color, but

that does not mean

that other potential

clients will want to use

that same special

color.

At the same time,

the architect and

designer (A&D) community has always been driven to create

unique signature solutions that establish a brand

identity unique to the product. Architects and designers

working on such architectural applications as lighting,

store fixtures, furniture, point-of-purchase

displays, signage and

glazing want to create interesting

looks, without using only the

cheapest, standard stocked products.

They are also looking to

use more finishes to get a physical

texture with a tactile or

dimensional quality. The trend is

to draw the consumer’s eye with beautiful but subtle

effects that give an added sense of luxury, value and style.

Another design trend at play is the need for more environmentally

friendly “green” products, using recycled

materials, or satisfying building requirements found in the

U.S. Green Building Council’s Leadership in Energy and

Environmental Design (LEED) certification program. The

internationally recognized green building certification system

verifies that a building uses materials that improve

environmental performance.

In short, the A&D community needs companies that can

create interesting

looks using standard

products, without

requiring huge runs.

To fill the gap between

what major acrylic

sheet manufacturers

can supply quickly

and cost effectively

and what the A&D

community is looking

for, some U.S. companies

are working on

ways to produce stylish

and innovative

products efficiently

and without long lead

times. The need for a

changed business

model is a reasoned response to the urgent need to adapt

or perish in the face of competitive pressures.

For example, Acrilex has spent the last decade adapting

to these new realities by developing a much more efficient methodology for customization.

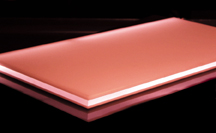

The result is called

Acriglas Combinations, in

which one side of a standard

clear sheet is colorized to

create a custom-colored

sheet. The process is not

simple – there’s still a distinct

element of art to make

the sheet uniform and free of

inclusion.

Say a customer wants a

3/4” thick piece of acrylic

with a special color that meets its brand requirements. In

the past, we would have cast the sheet in the color or gone

to a supplier to obtain it. Since overseas suppliers now

require custom products to be ordered in huge quantities,

we have developed a way to add the customized color to

the back of a stock sheet. The process offers one sheet

color matched from inventory in a very short time with no

minimum, a good way to get very small quantities of innovative

products for an affordable price.

Say a customer wants a

3/4” thick piece of acrylic

with a special color that meets its brand requirements. In

the past, we would have cast the sheet in the color or gone

to a supplier to obtain it. Since overseas suppliers now

require custom products to be ordered in huge quantities,

we have developed a way to add the customized color to

the back of a stock sheet. The process offers one sheet

color matched from inventory in a very short time with no

minimum, a good way to get very small quantities of innovative

products for an affordable price.

What has also changed is the ability to do this color mixing

much more efficiently. Where once customization

might have been achieved by mixing seven colors, we now

use three or four colors to achieve the same effect in the

combination sheet.

Since Acrilex is a distributor, a final

feature of the approach that also

reduces costs to customers is the elimination

of the additional markup from

product distribution.

For example, for AT&T Wireless

retail stores, Acrilex developed an

Acriglas Combinations sheet for a cellular

phone display shelf backdrop

that would enhance the company’s

brand identity as well as co-branding

with the distinct and recognizable look

of Apple.

To develop the product, Acrilex

started with a standard clear acrylic

sheet with a matte finish on one side

and then colorized and laminated a

1/8” sheet to it to produce a sheet

with a total thickness of 1/2”. The

sheet conceals the mechanical fasteners

and security hardware to which

the shelf is mounted, while giving the

illusion of color and depth. Combining

custom with stock material, the work

used a custom cast sheet in the company’s

orange color, with a white clear

Combinations sheet for the display

shelves backdrop. The store fixture

manufacturer supplying AT&T [the

company] just took the shelves and

installed them. The project, which

began with producing 10 sheets to

test the concept, is now in

place in all the AT&T stores

around the world.

Supply issues are indeed

having a chilling effect all

along the supply chain, from

the A&D community, to fabricators,

to distributors. The

A&D community is faced with

the prospect of sacrificing

innovation because they cannot

obtain specialty materials

for other than enormous

runs. Fabricators are finding it more difficult to meet customers’

needs, and distributors are unable to obtain material

that was formerly plentiful in the market.

What is the solution? Firms that can capitalize in the

void in the market by developing alternatives that give

customers custom-colored and textured specialty plastic

materials at affordable prices are well-placed to fill a real

and growing need.

Written by Dan Rustin, Acrilex, Inc. manufacturers of

Acriglas®.

For more information, contact Dan Rustin,

Acrilex, Inc., 230 Culver Avenue, Jersey City, NJ 07305,

800-222-4680, Fax: 201-333-1237, E-mail:

drustin@acrilex.com, Web: www.acrilex.com.

|