|

Fab Machinery and Tooling

High Surface Finishes in

Plastics

Typically, when a ball nose tool is used to machine contours

in plastic, the surface finish is a slightly irregular

with evident tool marks. While this finish is acceptable in

most applications, it is not acceptable in many medical

components, such as a knee replacement part. A knee

replacement includes an insert made of mechanical plastic

material. The plastic insert ensures smooth rotation

between the metal components of the implant.

The mechanical plastic insert requires a very

low Ra (roughness measurement), which

visually is a highly polished finish. Metal machined

components can achieve a

high polish using abrasives in a

secondary operation. Abrasives

cannot be used on plastic, as

the abrasives will roughen

the surface of the plastic.

To achieve the surface finish

required for the plastic insert, LMT Onsrud Cutter has

developed an innovative solid carbide ball nose tool that

will be available fourth quarter 2010. The new tool’s

unique geometry, specially designed

point and highly polished primary

clearance and flute give the tool the

ability to attain a surface finish of 28

Ra in mechanical plastic. A 28 Ra surface

finish is more than satisfactory

for the knee insert.

Other industries that will benefit

from the new ball nose tool include

food processing and electronics. In

any plastic application where the surface

finish is critical, companies will

want to take advantage of Onsrud’s

new ball nose tool.

For additional information, contact

Leslie Banduch, Onsrud Cutter LP,

1081 S. Northpoint Blvd., Waukegan,

IL 60085, 847-362-1560, Web: www.onsrud.com.

Creative Dollars

for Machinery

Creative Dollars

for Machinery

CDM Industries announced a bold

new idea to assist startup and existing

companies in acquiring the right

machine tool for the job. Plastic fabricators

and distributors very often

pass up on quoting jobs because they

do not have the right tool

for that job. It pays to

have the right tool, but

many companies have a

tough time justifying the

initial cost.

They offer an array of

machines such as dust collectors,

panel saws, table saws, CNC

routers, lasers, etc. for sale or hire on a

weekly, monthly and yearly basis. Let them know what you

need and they

will be happy to

give you a

price. Their

equipment is

also for sale

and if you find

that the

machine you are

renting should

become a permanent fixture they will

take any money paid in rental fees on an

existing rental towards the purchase price of the machine.

equipment is

also for sale

and if you find

that the

machine you are

renting should

become a permanent fixture they will

take any money paid in rental fees on an

existing rental towards the purchase price of the machine.

CDM (Computer Driven Machinery) Industries is a full

service machinery sales and service company offering

machinery repair, PM, installation and instruction, re-location

and remote programming service to customers from

coast to coast. With more than 25 years experience in the

plastic cutting industry, they are your one-stop shop for all

your machinery needs.

For additional information, contact Cahir McCoole, CDM

Industries, P.O. Box 883, Marblehead, MA 01945, 781-

608-4400, E-mail: cdmindustries @aol.com, Web:

www.cdm-industries .com.

Green CNC™ for Dense

Plastics

Accu-Router recently shipped its latest Green CNC to a

Pennsylvania plastics fabricator who purchased their first

CNC router in 1980, which Accu-Router took back as a

trade-in. The same customer purchased their second CNC

router from Accu-Router in 1983.

A number of factors defined this project’s success.

Paying cash, Accu-Router re-acquired the original 1989

platform from a major boating customer in North

Carolina. The original 1989 CNC control had been

upgraded along the way due to

water damage,

resulting in a

late-model Fanuc

18i-MA control

and extra value

for the right

Green CNC

application.

The retail

value of a

Fanuc CNC

control package

is

$50,000+, which can exceed the entire price of a lighter

machine with off-brand or PC-based electronics. As part of

the transaction, Accu-Router was able to offer a trade-in

credit for an inactive 1980 Porter router, which was

hauled back to its factory after delivery to be modernized

for yet another customer.

Other system highlights include: full one-year new

machine warranty, 15 hp cast iron power drawbar spindle,

built and serviced in Tennessee with lifetime loaners;

8-position automated tool rack with rotary actuated

chip cover.

Accu-Router’s Green CNC program means a number of

“non-wear” structural components are inspected, cleaned

and reused, representing great savings versus the cost of

all new. Such items on this Accu-Router included the heavy

steel weldments, thick aluminum jig plate table and

NEMA-12 (dust tight) electrical cabinets. The machine was

provided with a vacuum holddown system and a 15 hp

Travaini liquid ring vacuum pump (new). This customer has

four other CNC routers (three are Accu-Routers). This new

Green CNC is the fastest, most versatile of their machines.

It was also the least expensive.

Accu-Router factory technicians also performed a courtesy

written inspection of the customer’s existing three

Accu-Routers to maximize their performance and life

expectancy.

Besides offering customers “buy, rebuild, sell back”

options on Accu-Router machines, the company is also

actively expanding its Green CNC services to other fixedgantry,

ballscrew-drive routers; potential brands include

Shoda, Komo, Northwood, and Heian.

For additional information, contact T.R. Herzog, Accu-

Router, Inc., 634 Mountain View Industrial Drive,

Morrison, TN 37357, 800-239-5778/931-668-7127,

Fax: 931-668-9187, E-mail: info@accu-router.com, Web:

www.accu-router.com.

Large Selection of New &

Used Equipment

When in the market

for used or new

equipment, Ex-

Factory Inc. offers

quick and easy

access to over

6,000 listings of

used machines on

www.exfactory.com

and over 1,200

new machines on www.FactoryNEW .com. Used and new,

select from 475 CNC routers, 450 panel saws, hundreds

of peripheral equipment such as compressors, dust collectors,

electrical components, material handling equipment,

fork and scissor lifts and more.

For immediate buying opportunities and competitive

pricing, frequently visit their online auction website at

www.ExfactoryAuctions.com for exceptional value in a

wide

range of

equipment.

With

over 20

years in

the industry,

25

industry

experienced

Product Managers, value-added services and the

widest variety of equipment this industry has to offer, Ex-

Factory Inc. is the place to go For additional information, contact Norman Schust, Ex-Factory Inc., 1805 Sardis Road North, Charlotte, NC

28270, 704-841-2001 x445, Fax: 704-841-1200,

E-mail: norman.schust@exfactory.com, Web: www.exfactory.com.

Higher Productivity Multi

Head CNC

One of the great strengths of the AXYZ Series machines is

their ability to have custom head configurations to suit

almost any specific

manufacturing

requirement.

This particular

example

shows how

five identical

cutting spindles

can be

mounted on

a single carriage

to allow

the production of five parts at the

same time.

These machines can have one or

two carriages each with up to three

cutting heads mounted on independently

controlled Z axes all driven by

precision ballscrews. To take this concept

even further, the machine could

also have two gantries each with its

own set of carriages and heads.

When multiple spindles are mounted

on the same carriage they can be

setup to operate together - as in this

five head example - in which case five

parts can be cut simultaneously for

maximum production. Alternatively,

each head could be fitted with different

tooling and configured to cut independently

of the other heads so that

jobs requiring multiple tools can be

processed without the need for an

automatic toolchange unit.

When you consider the range of cutting

heads that can be used - routing

spindles, knife units, drills and more -

and all the ways in which they can be

arranged on the machine either with

or without an auto toolchanger, the

possibilities are almost endless.

This is what makes the AXYZ Series

machine the most versatile in the

industry today and is why it is so popular

with discerning manufacturers who know exactly what

they need to make their business stand out from their

competitors and achieve that winning combination of productivity

and profitability.

For additional information, contact Greg Jenkins, AXYZ

International, 5330 South Service Road, Burlington, ON,

L7L 5L1, Canada, 905-634-4940, Fax: 905-634-4966,

E-mail: sales@axyz.com, Web: www.axyz.com.

Diamond Edge Polisher

AWED Corp. is now

offering the newest

Fermari polisher, the

ARIA 2 Diamond

Edge Polisher with a

polishing capacity of

62” long and up to

4” thick. The polisher

is equipped with

a 1 1/2 hp direct

drive, single-phase 220-volt spindle motor. It

will polish faster than any previous machine and still

have a high quality finish. A10 footer is also available.

Router Bits & End Mills

AWED also carries the Euracryl

end mills in solid carbide or

with monocrystalline diamond

cutters. The tooling creates a

highly transparent finish on

acrylic. Now you have the

opportunity to create shapes

with rounded, beveled edges

with your CNC or milling

machine and have a polished

finish. The tooling can put a

radius or bevel on the inside of

a straight hole from its diameter up to 20mm, to any

capacity of your machine (limited size bevel).

machine and have a polished

finish. The tooling can put a

radius or bevel on the inside of

a straight hole from its diameter up to 20mm, to any

capacity of your machine (limited size bevel).

In some cases you can polish steps in the thickness of

the material, either straight or bevel finish. You can also

polish a through hole with their special tooling (machinery

requirement differs). Special shapes available upon

request. The tools are available 6mm and 8mm shanks

with .05 radius on natural diamond and 6mm to 20mm

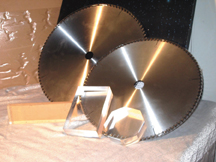

on PCD and carbide. TCG Saw Blades

AWED also offers

plastic cutting saw

blades with the

unique triple-chip

grind (TCG) tooth

design. It's design

offers a cut unequal

by any other blade.

These blades can be

used on standard

table saws or panel

saws, manual or CNC. A variety of sizes are available to

meet your specifications.

For additional information, contact Victor Miranda,

AWED Corp., 1175 Buford Highway, Suite 101, Suwanee,

GA 30024, 770-831-9800, Fax: 770- 831-7404, E-mail:

awedmachine@aol.com, Web: www.awedmachine.com.

Vertical Panel Saws

STRIEBIG vertical panel saws from Switzerland have a

renowned reputation for quality and precision cutting in a

wide variety of materials including most plastics.

STRIEBIG panel saws are safe, easy to operate and take

up a minimal amount of floor space compared to horizontal

saws, especially for larger sheets. STRIEBIG offers the

most complete range of machines with five models, each

with a wide variety of frame sizes from 5’x 10’ up to 10’ x

30’ and cutting depths up to 3 1/8”.

The COMPACT model offers STRIEBIG precision in a

basic manual machine but with many available accessories.

It is available with automatic

travel in the COMPACT AV

model. The

STANDARD

model is a

more powerful,

still

basic

machine

and available

with a full-wood back support panel for thinner material.

The newly redesigned top-of-the-line CONTROL

model is a fully automatic machine with touch-screen controls,

digital measuring, the full-wood back support, automatic

set-up features and new optional programmable

trimming, measuring and cutting.

For additional information, contact David Bull, Colonial

Saw, Inc., 122 Pembroke Street, P.O. Box A, Kingston,

MA 02364, 781-585-4364, Fax: 781-585-9375, E-mail:

dbull@csaw.com, Web: www.csaw.com.

Precision Machining

Products

C.R. Onsrud, Inc. offers a comprehensive line of high-precision

machining products including over fifty standard

models of 3-, 4- and 5-axis CNC routers, four models of

Inverted Pin Routers, as well as a complete line of tooling

and accessories. CNC routers are offered in cast-iron fixed

bridge, twin table, single table, and steel frame moving

gantry designs.

Most C.R. Onsrud CNC routers include a

12-position tool changer, high grade

“off-the-shelf” standard components,

24/7 tech-support, and all can be

customized via a full menu of standard

options including: multispindle

drills,

aggregate

capability,

rotational

C-axis, 5-axis, multi-spindle and dual process configurations.

C.R. Onsrud is known for superior service capabilities,

high-tech training facilities and an extensive

Applications Engineering department to further reinforce

their pledge to provide the industry with the best products,

service and customer support.

For additional information, contact Alyson Onsrud, C.R.

Onsrud Inc., P.O. Box 419, Troutman, NC 28166, 800-

638-8185/704-528-4528, Fax: 704-528-6170, E-mail:

sales@cronsrud.com, Web: www.cronsrud.com.

Saw Blades for Plastics

FTM, Inc., offers a large selection

of saw blades specifically designed

and manufactured for cutting all

types of plastics. They stock blades

manufactured by General Saw

Corp., a name synonymous with

cutting excellence within the plastics

industry. General Saw gives

meticulous attention to every

aspect of saw blade engineering

and design, producing precision saw blades, which exceed even the most

critical cutting needs. Things to keep in mind when selecting a saw blade are

the thickness, hardness and heat sensitivity of your plastic. The thinner the

plastic the more easily it will chip, therefore the more teeth the blade will

require, the lower the rake angle and the thinner the kerf. The harder the

plastic is, the more likely it is to chip, also requiring more teeth. Heat sensitive

plastics require fewer teeth, more radial clearance angle and more

tooth overhang.

Use these guidelines to select the best blade for your material: use the maximum

number of teeth to reduce or eliminate chipping but cut back on the

number of teeth when smearing (overheating) begins to occur; use a blade

with the thinnest practical kerf; use stiffening collars when possible; and

always service your blades at the first sign of dulling.

For more help selecting the perfect saw blade, visit FTM’s website and click

on the "SAW-LECTOR GUIDE" for blades.

For additional information, contact David Geer, FTM, Inc., 327 Industrial

Drive, Unit 1, Placerville, CA 95667, 530-626-1986, Fax: 530-642-2602,

E-mail: info@123ftm.com, Web: www.123ftm.com..

Vertical Beam Saw Series

Hendrick’s line of heavyweight, fully automatic vertical beam saws feature the

precision accuracy needed to stack cut and cross-cut all-sized parts while

requiring minimal floor space. Hendrick PRO-V Vertical Beam Saws have full

length heavy-duty pneumatic pressure beams and squaring fences to provide

confirmed placement of material while cutting,

solid frames and surface areas to maintain squareness

and support. Featuring ±.005” of straight

line accuracy, an operator merely needs to

place the material against the stop, press the

button to activate the hold-down bar and then

press the start button to rip or cross-cut anything

ranging from less than 1/2” squares up to

10’ sheets.

The compact saw offers single blade scoring

and three cutting modes: normal,

reciprocating and scoring.

Driven by a 9 hp motor, the

adjustable saw blade travels on precision

machined ways and the 2 hp variable

speed automatic saw carriage traverse motor by

AC inverter is standard with speeds up to 75 fpm. The machine’s small footprint

saves valuable floor space.

For additional information, contact Whitney Wiggin,

Hendrick, 32-34 Commercial Street, Salem, MA 01970,

978-741-3600, Fax: 978-744-0242, E-mail: info@

hendrickmanufacturing.com, Web: www.hendrickmanufacturing.com.

Saw Blades for Cutting

Plastic

Forrest Manufacturing offers several quality blades

designed specifically for plastic applications. These blades

feature specially tipped, abrasive-resistant, double-hard

C4 micrograin carbide for 50% to 300% longer life

between sharpenings.

Like all Forrest products,

they are made in

the United States and

come with a 30-day,

money-back guarantee.

The following blades

can be ordered direct

from the factory or from

quality dealers, retailers

and catalogs: No-Melt

Saw Blades cut single

or multiple stacked sheets of plastic—without chipping or

melting these materials. They are particularly suitable for

acrylics, delrins, ABS, PVC, and both high- and low-melt

nylons. Carefully engineered side clearances on the carbide

teeth significantly reduce or eliminate melted burrs

and residue buildup. Duraline Thin-Rims for Plastikerf and

Plycutter Saws. These blades cut fine, fragile, and/or thinwalled

material such as 1/32” to 1/4” acrylic sheets,

engraving stock, curved formica sections, plastic extrusions,

etc. Duraline Thin-Rims eliminate chipping, minimize

tooth impact and reduce material waste. Duraline

Circular Saw Blades are suited for extra fine, chipless sawing

of acrylics and plastic sheets and for fine sawing of

ABS, acrylics and PVC.

For additional information, contact Jay Forrest, Forrest

Manufacturing Company, 457 River Road, Clifton, NJ

07014, 800-733-7111/973-473-5236, Web: www.forrestblades.com.

5-Axis CNC Machine

MAAC Machinery, a leader in the manufacturing of thermoforming

machinery, is producing a line of 5-axis CNC

routers to the thermoforming industry, labeled Royce

Routers.

The Royce Router is equipped with two 5’ x 5’ tables

that can be used independently or in tandem to accommodate

a 10’ x 5’ working area. This router is designed

specifically for the maximum production of trimming thermoformed

parts with

a focus on

higher

speeds,

allowing

thermoformers

to

match the

output of

rotary thermoforming

machines.

This allows processors to not only speed secondary

processes but eliminates the need for multiple “slower”

trimming machines typically required to provide an equivalent

output. The Royce line is equipped with top of the

line Fagor controls, 10 hp (2400 rpm) spindle(s), and is

available in both 36” and 48” z strokes.

This addition to the MAAC line up allows them to now

provide complete processing cells; from forming equipment

and molds, to trimming equipment and trim fixtures.

With the ability to provide everything from a single source,

MAAC can greatly reduce project timing, pre-set all processing

parameters, greatly reduce learning curves and

assure complete cell integration.

For additional information, contact Michael P. Alongi,

MAAC Machinery Corporation, 590 Tower Boulevard,

Carol Stream, IL 60188, 800-588-MAAC/630-665-1700,

Fax: 630-665-7799, E-mail: sales@maacmachinery.com,

Web: www.maacmachinery.com.

CNC Router for the

Plastics Industry

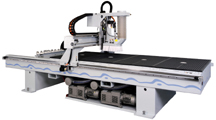

MultiCam, Inc. offers an innovative, heavy-duty, precise

cutting system to the plastics and acrylic fabricator. Our

top-selling 3000 Series CNC Router is loaded with standard

features normally associated with more expensive

machines. The rigid, all-steel plate frame construction coupled

with our new automatic rotary tool change, 8.5 hp,

40,000 rpm spindle allows for an incredible edge finish

when machining

plastic.

The 3000

Series router

also comes in

a wide variety

of table

sizes and features

a space

saving, moving-

gantry

design. In

addition,

MultiCam has vacuum fixturing options specifically tailored

to the plastics industry.

MultiCam Inc. has over 70 distributors worldwide,

including 20 Technology Centers in North America, so you

can always depend on local training, support and service.

For additional information, contact John Harris,

MultiCam LP, 1025 West Royal Lane, DFW Airport, TX

75261, 972-929-4070, Fax: 972-929-4071, E-mail:

leads@multicam.com, Web: www.multicam.com.

High Precision Saw

High Precision Saw

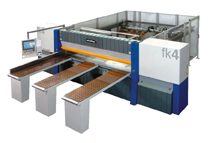

Schelling announced their new fk4 panel saw designed

and engineered specifically for high speed, precision cutting

of plastic panels. This includes acrylic, PETG, polycarbonate,

polyolefins, PVC,

UHMW, phenolics,

mechanicals

and other specially

engineered

materials.

The fk4

provides

extremely

tight cutting tolerances

and chip-free cutting

of material as thin as .020" without the use of a protection

board. The machine is also equipped with material

recognition software, a saw blade change database and

total panel control features that provide fast setup times

when changing materials.

Additional features include: rigid heavy duty construction;

state-of-the-art material handling technology that

automates the loading, cutting and off loading processes;

on-line remote diagnostics for increased uptime and productivity;

saw blade rpm control combined with blade

cooling; online downloading of optimized cutting patterns

and label printing.

For additional information, contact Stephen Bailey,

Schelling America, Inc. P.O. Box 80367, Raleigh, NC

27623, 919-544-0430, Fax: 919-544-0920, E-mail:

sbailey@schelling.com, Web: www.schelling.com.

Nested-based CNC

Routing

Stiles Machinery Inc. introduced a solution for nestedbased

CNC routing that delivers excellent quality at an

affordable price. Stiles observed that nested-based CNC

routing continues to gain momentum as an efficient manufacturing

process but their customers needed a costeffective

solution in today’s economic climate. Stiles

shared their customers’ requests with Weeke Mas -

chinenbau to engineer an entry-level CNC router. Based in

Northern Germany, Weeke is one of the world’s largest

manufacturers of CNC equipment. Stiles has been

Weeke’s exclusive distributor in the United States for over

20 years. The outcome of these collaborative efforts is the

Weeke Vantech series of CNC routers.

For routing panels, the Vantech delivers maximum flexibility

and easy integration

with popular

CAD/CAM software

packages.

But

German

engineering

alone did

not fulfill the expectation

of Stiles and their customers.

Stiles viewed the slow economy as an opportunity

to pursue new strategies, so they considered another

option. By manufacturing in the United States, they could

build machines for less without factors such as fluctuating

exchange rates and international shipping costs. German

engineered quality at an American-made price.

Primarily designed for nested-based machining, the

Vantech series of routers incorporates the advantages of

Weeke performance at an affordable price.

Available in 4’ x

8’, 5’ x 10’ and 5’ x 12’ table sizes, all of the models are constructed

with an extremely durable foundation to accommodate

the CNC router’s high-speed capabilities while

ensuring the machine’s longevity. Windows-based programming

software is a standard feature for maximum flexibility

and easy integration with popular design packages. Other

features include Quik-Pod system for added flexibility, dual

drive gantry and pneumatic positioning pins.

For additional information, contact Amanda Dombeck,

Stiles Machinery Inc., 3965 44th St. SE, Grand Rapids, MI

49512, 704-861-8239, E-mail: adombeck@stilesmachinery.com, Web: www.stilesmachinery.com.

Gantry Machine Platform

Techno, Inc. Linear Motion Systems announced the New

TechnoMod Gantry Machine, a multi-axis motion platform

complete with controls, cabling, software and enclosure;

all fully assembled. The TechnoMod is available in three

different sizes and can be used for pick and place, dispensing,

assembly, testing, drilling, routing, welding and

general automation applications.

Joe Griffin,

Techno Linear

Motion Sales

Manager, states,

“The New

TechnoMod

machine is completely

assembled

when it arrives.

All electronics are

wired and software

installed,

allowing customers

the ease

of running the

machine in any

work cell shortly.

The only setup customers may have to perform is the

mounting of drill, dispenser, laser or automation tooling

required for their application and in many cases Techno

can do this for the customer prior to shipping.”

Travel ranges are 650 x 300 x 275 mm for the Model

30, 650 x 450 x 275 mm for the Model 45 and 650 x

650 x 275 mm for the Model 65. Additionally, a 4th or

5th rotary axis can be added to the machine for more

complex operations, while all drive motors are DC brushless

servos providing high torque and precision. The

TechnoMod can be delivered with or without electronics as

well as a sliding front door with safety interlock. It has a

built-in industrial computer and rugged swing arm console

which includes a monitor and keyboard.

For additional information, contact Joseph Griffin,

Techno, Inc., P.O. Box 5416, New Hyde Park, NY 11042,

800-819-3366/516-328-3970, Fax: 516-358-2576,

E-mail: tooling@technocnc.com or cncinfo@technocnc.com

Web: www.techno-isel.com.

New & Used Equipment

PlastiMACH Corp. is a

stocking dealer of

used plastic thermoforming

and plastic

processing equipment

since 1975. Most of

their late-model inventory

can be inspected

in New York or

Chicago warehouses.

They also represent all major manufacturers of new thermoforming

machinery, including single station, rotary double

end and inline equipment. They can help you select the

right machine for your application and budget, with over

75 years of experience in the thermoforming and routing

industry.

PlastiMach Corp. also introduces their CNCrouter -

store.com division. In addition to a wide selection of new

and used

CNC

Routers,

The CNC

Router

Store staff

specializes

in assisting

buyers

locate the

appropriate

equipment

for

their particular

application. With their large selection they have

machines for every budget. They carry used CNC routers

from Thermwood, Motionmaster, C.R. Onsrud, Komo,

Quintax, Multicam, Anderson, Omnitech and others. They

also carry the new line of CNT Motion Systems and FMT

CNC Routers with complete 3-axis CNC Router packages.

For additional information, contact Jerry Hammerman,

plastiMACH Corp., 704 Executive Blvd., Valley Cottage,

NY 10989, 845-267-2985, Fax: 845-267-2825, E-mail:

mailto:jerryh@plastimach.com, Web: www.plastimach.com.

Gantry-Based CNC

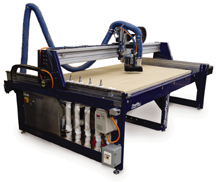

ShopBot’s PRSalpha CNCs are tough, sophisticated,

gantry-based CNC routers. Using advanced technology for

CNC cutting, drilling, carving and machining, the

PRSalpha is right in professional environments where production speed is

important, delivering

rapid transit

speeds of 1800

inches per

minute and cutting

speeds of up

to 600 inches per

minute. These

ShopBot CNCs

boast robust Vexta

alphaStep motors, an innovative

hybrid combining the quick motion and speed of stepper

motors with the closed-loop feedback advantages of

servos.

Easy to assemble, configure and re-configure,

learn and use, the PRSalpha CNC delivers reliable, affordable,

full-production performance in digital fabrication of

wood, plastic, aluminum and other materials.

The ShopBot PRSalpha features fast, closed-loop Vexta

alphaStep motors, tough precision bearings and hardened

steel rails, reliable rack-and-pinion power transmission,

step resolution of .0004", positional accuracy of +/-

.002", Z-zero Touch-Off Plate and XY Proximity Switches,

advanced ShopBot Control System software, user-friendly

ShopBot PartWorks Software Suite, free tech support and

a two-year warranty.

The CNC is offered in four popular table sizes: 48 x 48,

96 x 60, 120 x 60 and 144 x 60 with custom sizes and

special adaptations available to meet your specialized

production needs.

For additional information, contact ShopBot Tools, Inc.,

3333B Industrial Drive, Durham, NC, 27704, 919-680-4800/888-680-4466, Fax: 919-680-4900, E-mail: see their website, Web: www.shopbottools.com.

Polish Acrylic

on a Sliding

Table Saw

Polish Acrylic

on a Sliding

Table Saw

The German woodworking machinery

company, MARTIN has develop

an option for the MARTIN T74 saw

that would make it possible to finish

polishing of acrylic panels directly

after cutting them. The drive of the

sliding table was fine tuned for polishing.

The pressure bar is divided

into several clamping areas, which

can be used independently ensuring

gentle and firm clamping of smaller

and bigger workpieces. A special

fence included in the package

makes it easier to position the workpieces

to be polished. Even

whole stacks of acrylic

plates can be positioned for

polishing without difficulty

at the 2 m guide. Acrylic

plates as well as whole>

stacks of material, with an

edge length of up to 3,000 mm and a thickness of up to

100 mm, can be processed effortlessly.

stacks of material, with an

edge length of up to 3,000 mm and a thickness of up to

100 mm, can be processed effortlessly.

The package includes the polishing unit, including tool

protection, dust extraction hood and lifting device which

can be lifted and lowered manually. The polishing unit can

only be used with Euracryl ES-100 tools (not included in the

package) polishing a maximum thickness of up to 100 mm.

Planer for Plastics

MARTIN has also

developed a planer

designed for the

processing of plastics.

Specific

machine options

such as a vacuum

table for the processing of thin material, a zinc-coated

dust collection shroud to reduce static and a cutterhead

with an 18°hook angle are designed into the MARTIN

T45 planer. MARTIN also offers its T45 Contour planer

with these options, which allows for the profiling of plastic

material up to 24" wide with a 1" depth of cut.

For additional information, contact Carl Stout, Martin

Woodworking Machines Corp., 8107-M Arrowridge Blvd.,

Charlotte, NC 28273, 704-525-3963, Fax: 704-525-

3443, Web: www.martin-usa.com.

General Purpose &

Precision Saw Blades

General Purpose &

Precision Saw Blades

Craftics provides a variety of tools and accessories for

working with plastics, including Tenryu Saw Blades. They

inventory the Tenryu Plasti-Cut and Pro Series Blades for

Plastics in a variety of sizes and grades.

The Plasti-Cut blades are designed for general purpose

cutting on a variety of materials and material thickness.

High grade

carbide

teeth

and an

ultrathin

kerf

will

allow

faster

feeding

and

minimal waste. They provide exceptional performance for

a value price. Craftics offers 7-1/4”, 10”, 12” and 14”

diameters from stock.

The Pro Series blades are superior quality, high-precision

blades that offer fine-grain, wear-resistant carbide

teeth for long life, expertly tensioned steel bodies for true

and accurate cuts, built-in expansion slots act as dampeners

to reduce vibration and noise. Achieve precise professional

cuts in production applications time after time.

Craftics offers 10”, 12” and 14” diameters from stock.

Craftics also offers the Craftics Brand Plasticutter and

Edgescraper and Onsrud Cutter Router Bits and can

sharpen your saw blades.

For additional information, contact Tracy Pineda,

Craftics, 2804 Richmond Drive NE, Albuquerque NM

87107, 866-296-2130, Fax: 800-289-2020, E-mail:

sales@craftics.com, Web: www.craftics.com.

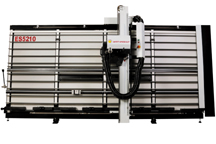

Panel Saws

Safety Speed currently offers nine different panel saws.

Their full line of panel saws are engineered to be low cost,

highly efficient and extremely safe to use. Each machine

has a guaranteed alignment built right into the machine

and calibrated within factory specifications.

From their C4 and C5 models which pack all the features

of full-size saws into a portable 5' frame to their

ES5210 Panel Saw designed for high production and tight

tolerance cutting, Safety Speed strives to provide their

customers with equipment that improves productivity,

quality, safety and bottom line profitability. Ideal for cutting

plastics, their top of the line ES5210 machine is

equipped with a 7 Hp, 3~, 220V motor. The European

Style traveling carriage traverses the full length of the

machine frame to execute cuts on full size sheets up to

61" tall and 130" long with cutting accuracy of 0.005"

straight

and

square.

The

traveling

beam

allows

the

operator

to leave

the

panel

stationary while the cutting blade moves both horizontally

and vertically.

Standard Equipment includes built in gauges with

length stops, integrated dust collection system, stops for

horizontal cuts, self-moving panel supports, MID-WAY

FENCE™ System and quick change from vertical to horizontal

cutting.

For additional information, contact Tom Houska, Safety

Speed Mfg., 13943 Lincoln Street N.E., Ham Lake, MN

55304, 800-772-2327/763-755-1600, E-mail: sales@safetyspeed.com, Web: www.safetyspeed.com.

Micro Flute Polishing on

Plastics Tooling

Vortex Tool Company, Inc.

recently introduced a new

proprietary process of polishing

the flutes of their

router bits used in the plastics

industry. The process

imparts an extremely high

finish quality on the surface

of the cutting face and flute

area of the bit. For the user,

this means better cut quality,

longer tool life and less

chance for chip re-welding or sticking to the tool itself.

This new process is now used on all Vortex Tool’s plastic

cutting router bits.

Vortex Tool Company, Inc., designs and manufactures a

wide variety of standard and custom high-performance

router and insert cutting tools for the woodworking and

plastics industries, and provides re-tipping and sharpening

services.

For additional information, contact Mike Serwa, Vortex

Tool Company, 5605 Jelinek Avenue, Schofield, WI

54476, 800-355-7708, Fax: 715-355-7353, E-mail:

mikes@vortextool.com, Web: www.vortextool.com.

|