|

Nylon & Acetal Shapes

Security Against

Contamination

TECAFORM AH

ID (POM-C) is

the first stock

shape thermoplastic

that can

be easily and

quickly detected

if equipment

failure causes

pieces of material

to mix with

the food product during the production run. The plastic

contains an additive which enables it to be more readily

detected in the event of an equipment failure. TECAFORM

AH ID can be detected using standard metal detection

equipment during routine quality inspection procedures.

Prior to the introduction of TECAFORM AH ID, only highly

visible, or specially colored materials would typically be

used in production. However, even these parts are not

always noticeable once the product has been contaminated.

This often makes large quantities of the finished product

unusable, causing significant downtime and potential

financial loss.

This grey acetal is easily and quickly detected by metal

detectors, enabling prompt quality assurance and minimizing

potentially costly quarantines and recalls.

TECAFORM AH ID is made from resin that is FDA and 3A

Dairy compliant. Its resistance to chemicals and cleaning

agents make it ideal for use in the production of meat patties,

sausages and other formed foods, fruit juices, pasta

and pastries, as well as applications in food and pharmaceutical

packaging. In addition to being easily detected,

TECAFORM AH ID features all of the technical properties

needed to produce high quality plastic components for

food processing and other machinery. The product is

being used in housing parts, agitators, kneading elements

and wiper blades for the food industry.

For additional information, contact Bruce Dickinson,

Ensinger, Inc., 365 Meadowlands Blvd., Washington, PA

15301, 856-227-0500, Fax: 724-746-9209, E-mail: sales@ensinger-ind.com, Web: www.ensinger-online.com.

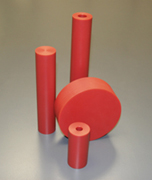

Acetal Rod & Sheet up to

8” Thick

GEHR expanded its acetal product program and inventory.

They now feature the broadest range of diameters and

thicknesses available in the industry.

GEHR is the first to offer co-polymer acetal sheet up to

8” thick. They also now offer 48” x 120” acetal sheet.

GEHR offers next-day shipments due to large stocking

inventory. Their materials

are FDA, USDA and

3A Dairy compliant.

They use high grade

BASF Ultraform® H4320

resin as well as other

well known acetal resins.

GEHR uses copolymer

for elimination of centerline

porosity and all rod

and sheet sizes are in

line stress relieved as

well as secondarily air

annealed for superior

machinability and

dimensional stability.

GEHR Acetal rods are available up to 20" and are centerless

ground to exacting tolerances up to 2” in 10”

lengths. Sheet is available in 24” x 96”, 48” x 120” sizes.

GEHR offers acetal co-polymer, ELS (electrically conductive),

ESd (antistatic) and WEARGEHR Acetal FG featuring

enhanced wear-resistance.

For additional information, contact Bill Shields, GEHR

Plastics USA, 24 Creek Circle, Boothwyn, PA 19061, 800-

PVC-GEHR/610-497-8941, Fax: 610-497-8901, E-mail:

info@gehrplastics.com, Web: www.gehrplastics.com.

Copolymer Acetal

Rochling Engineering

Plastics SUSTARIN¨ C

(Acetal) is a general purpose

copolymer

acetal that is porosity

free. The technology

used in their manufacturing

process ensures

that every sheet and

rod is free of centerline

or core porosity.

SUSTARIN C is easily

machined with excellent

dimensional stability for close tolerance parts. A low

coefficient of friction and excellent wear properties, especially

in wet or moist environments, make it easy to see

why SUSTARIN C is one of the most widely used engineering

thermoplastics available today.

They offer the following certification for their acetal:

ASTM POM 0211, D6778, FDA21 CFR 177.2470, ASTM

POM 211, D 6100 and the material is USDA compliant.

For additional information, contact Birgit Moecks, Rochling Engineering Plastics, 903 Gastonia Technology Parkway Dallas, NC 28034, 704-884-3506, Fax: 704-922-1835, E-mail: birgit.moecks@roechling-plastics.us, Web: www.roechlingplastics.us.

New Self-lubricated Cast

Nylon

Nylatech PVM (pressure/velocity/maximum) was

developed to provide a

premium material for a

variety of applications.

Nylatech PVM is a self-lubricated

material with a

low coefficient of friction

that can increase the life

of equipment.

The material is internally

lubricated, minimizes

maintenance, improves

part life, improves life of

mating component, reduces machine/equipment noise,

offers a lower coefficient of friction and superb machinability

and surface finish.

Nylatech PVM offers exceptional PV (pressure times

velocity) values resulting in an excellent material for tough

load bearing/frictional applications. It is available in rod,

sheet and tube. Custom parts available.

For additional information, contact Calvin Petersen,

Nylatech, Inc., P.O. Box 455, Everson, WA 98247, 800-506-9566/360-966-2838, Fax: 360-966-2838, E-mail:

nylatech@nylatech.com, Web: www.nylatech.com.

Solvent Welding Nylon

IPS Weld-On¨ Number 1701 will

bond most nylon formulas like

type 6 and type 66. Weld-On

1701 is a clear, water-thin solvent

cement. To use you simply

apply a thin layer to one or both

surfaces, allow 30 seconds then

apply pressure until initial set

takes place. Weld-On 1701 is

available in pints from Quick

Seal Inc.

For additional information,

contact Max Plumhoff, Quick

Seal Inc., 50671 Tarrington Way, Granger, IN 46530,

574-272-8695, Fax: 574-272-5004, E-mail: max@quickseal.com, Web: www.quickseal.com.

|