|

Improving Efficiency In CNC Routing

If you are considering adding another panel saw or CNC

router to your operation, or if you are a first time CNC

buyer, you should consider the benefits of using Nested

Based Manufacturing (NBM). Nested Based Manufacturing or

“nesting” is a manufacturing method that many plastic distributors

and fabricators can adopt in order to improve the

efficiency of their new or existing CNC routing operation.

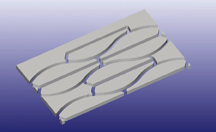

Simply put, Nested Based Manufacturing is a

process that utilizes a CNC Router to produce finished

parts ready for gluing, assembly or shipment to the customer

without presawing or secondary finishing operation.

It begins with part drawings (existing or newly drawn)

being optimized by software within the dimensions of a

defined sheet

size. The parts

are then machined

on the

CNC router in

the exact pattern

defined by

the software or

by the designer

out of a single

sheet. The

completed run

will look something

like a

puzzle. Parts

can be arranged to provide the highest possible material

yield and minimize waste. In addition to these benefits,

NBM can provide faster processing and fewer mistakes

due to reduced set up time and no required precutting.

While some jobs are better produced by cutting blanks

to size on a saw and then machining, many distributors

and fabricators are currently producing parts that could

be “nested” more efficiently. Because of recent advances

in CNC router technology, some parts traditionally “CNC

milled” or “machined from blanks” can be processed more

efficiently using NBM. Nested Based Manufacturing is an

alternative way of approaching fabrication and can be

used in conjunction with traditional CNC methods to maximize

efficiency and productivity.

Some examples of how NBM can improve efficiencies of

existing jobs are single part runs and multiple part runs to

include product components. In single part runs, some parts

are traditionally produced by first cutting blanks to size on

a saw and then machining those blanks on a CNC Router or

Mill. Utilizing NBM, the part would be optimized over a full

4’ x 8’ (or your standard size) sheet and machined in one

operation. This saves dual set up time, reduces material

handling, maximizes yield from the material and ensures

repeatable tolerances. With multiple part runs, several different

part shapes or multiple components of products such

as displays can be optimized using NBM. Different parts can

be combined to take advantage of the optimized material

yield and streamline several operations into one.

Another example of a good NBM application

would be the routing of 5 fi” diameter disks.

Conventional cutting and machining from blanks

would yield 128 parts from a 48” x 96” sheet as

compared to 135 pieces from the same sheet size

when NBM is utilized. In this case, the yield is

5.5% greater with less material handling and

labor content.

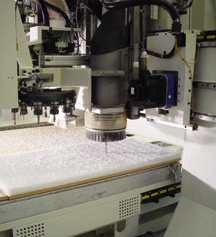

Machine Requirements

The necessary requirements for Nested Based

Manufacturing are a CNC router and software

with nesting capability. Depending on your needs,

single or multiple head machines can be used for

the nesting process. Important router features for

nesting include table size and design, vacuum

capability, chip evacuation, tool changing and

positioning speeds. For best results, the table size

should be large enough to accommodate your

standard size sheet material. A minimum table

bed of 4’ x 8’ or 5’ x 10’ is common.

The table

design should provide for enhanced vacuum hold

down with the flexibility to use many different

types of fixtures. State-of-the-art table systems

combine a high tech aluminum grid table with

large vacuum tubes evenly distributed below the

table to achieve strong, even hold down. Larger

parts can be held down during machining using a

blank, bleed-through spoil board; however the

nesting of smaller parts may require a specialized

spoil board or fixture to successfully hold down

the pieces. Because parts are machined in close

proximity, chip evacuation is crucial to obtain best results. An

excess of chips around the router bit can result in re-melting and

attaching to the tool, leading to a poor finish. The best chip evacuation

can be obtained by combining an ample dust/chip collector

with a CNC router that has an effective chip collection design. CNC

controlled dust hoods around the router bit with 360º pickup capability

are found on well designed chip collection systems. The ability

to change tools rapidly provides some of the efficiency benefit

when using NBM. A quick or rapid style changer with a minimum of

eight positions should be considered. A CNC router equipped with

this type of rapid tool-changer can move quickly from one operation

to the next with a minimum of lost time. Positioning speeds are an

important consideration for quick cycle times. Combined with a tool change, high speed movement from the end of one operation

to the beginning of the next can save as much as 10-

15% off normal cycle times.

Software

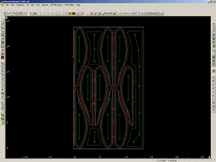

While many current software packages available with

CNC routers have a “nesting function” included in the

package, not all software is equal. In addition to important

features used for typical routing applications, key aspects

of software used

for NBM include

full 3-D simulation

and tool

path editing capability.

3-D simulation

allows a

user to review

the machining of

the part as programmed

allowing

an opportunity

to correct errors

or make

changes before any plastic is cut. This feature reduces programming

time and prevents unneeded waste of material.

When nesting small, hard to hold parts, it is important to

have advanced tool path editing capability for full manipulation

of lead in/lead out and tool insertion point. These

tools allow the programmer to quickly adjust router bit

point of entry and angle of attack in order to reduce pressure

on parts when routing. Using these advanced tools

can make the difference of being able to effectively hold

small parts down when machining.

CNC routers have a “nesting function” included in the

package, not all software is equal. In addition to important

features used for typical routing applications, key aspects

of software used

for NBM include

full 3-D simulation

and tool

path editing capability.

3-D simulation

allows a

user to review

the machining of

the part as programmed

allowing

an opportunity

to correct errors

or make

changes before any plastic is cut. This feature reduces programming

time and prevents unneeded waste of material.

When nesting small, hard to hold parts, it is important to

have advanced tool path editing capability for full manipulation

of lead in/lead out and tool insertion point. These

tools allow the programmer to quickly adjust router bit

point of entry and angle of attack in order to reduce pressure

on parts when routing. Using these advanced tools

can make the difference of being able to effectively hold

small parts down when machining.

Nest Based Manufacturing can provide efficiencies over

traditional routing methods when material handling costs,

material yield and

part repeatability

are important

considerations. If

you are considering

the nested

based approach,

have your staff

conduct an internal

study to

determine the

benefit of such a

process. Some

CNC Router manufacturers

can also provide you with “time studies” that

can measure the savings of moving jobs to NBM.

Written by Phil Bryant, Business Manager, Plastics for SCM

Group USA, manufacturers of CNC Routers and Computerized

Panel Saws.

For more information, contact SCM Group

USA, 2475 Satellite Blvd., Duluth, GA 30096, 800-292-

1850, 770-813-8818, Fax: 770-813-8819, E-Mail: info@

scmplastics.com, Web: www.scmplastics.com.

|