|

Sheet Offers Versatility In Product Development

Prototyping is a critical phase of

product development. Designers

and engineers must determine

how best to combine form and

function, aesthetics and ergonomics,

durability and performance in an

appealing package that’s coordinated

with market needs, while working

within their budgets. Multiple iterations

of product design are often necessary

before the right balance of

properties is achieved.

Prototyping is a critical phase of

product development. Designers

and engineers must determine

how best to combine form and

function, aesthetics and ergonomics,

durability and performance in an

appealing package that’s coordinated

with market needs, while working

within their budgets. Multiple iterations

of product design are often necessary

before the right balance of

properties is achieved.

And herein

lies a challenge: many design teams

work with tight budgets. This means

there is little leeway in the productdevelopment

cycle for experimentation

and adjustment, especially when

it involves costly delays due to

redesign.

And herein

lies a challenge: many design teams

work with tight budgets. This means

there is little leeway in the productdevelopment

cycle for experimentation

and adjustment, especially when

it involves costly delays due to

redesign.

“Nevertheless,” says Claude

Gidman, an award-winning industrial

designer and founder of Gidman

Design Associates Ltd., Toronto,

“engineers and designers can greatly

improve the properties and performance

of a product by refining key features,

including its shape.”

“At Gidman Design, we find that

the more we experiment with shape,

the greater the strength and quality

that can be obtained without

increasing cost,” he says. “Failing to

take advantage of creative shaping

opportunities can result in product

coverings which can be bland, less

effective functionally and less appealing

in the marketing process.”

Gidman says his company has

found efficient ways to quickly and

economically develop, test and make

changes to product-design concepts.

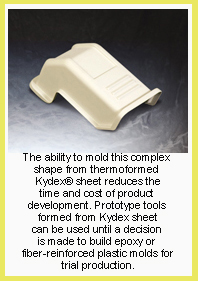

“We fabricate

prototypes and tooling

of Kydex® sheet, a thermoplastic

alloy that can be readily shaped with

thermoforming.”

prototypes and tooling

of Kydex® sheet, a thermoplastic

alloy that can be readily shaped with

thermoforming.”

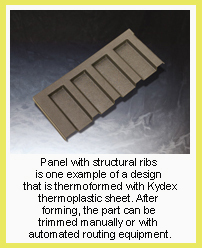

Kydex sheet,

manufactured by

Kleerdex Company, LLC, Bloomsburg,

PA, is effective for prototyping,

notes Gidman. The material can be

heat-fabricated or thermoformed into

complex shapes, making it suitable

for designs where it houses, supports,

protects or decorates products. It can

also be used like stamped or pressed

sheet metal to create covers and

enclosures but without the need for

surface treatment, complex tooling or

painting. It is rigid, durable, firerated,

resistant to impact and a variety

of chemicals and comes in a range

of standard and custom colors, sizes,

thicknesses and surface textures.

Kydex sheet also meets or surpasses

code requirements for many applications,

such as those in most transportation

interiors.

When properly designed, tooled

and formed, parts fabricated of

Kydex sheet don’t thin out at the

edges. Product developers can thus

use the material in a relatively lowcost

process like

thermoforming to

improve and test a design and undertake

pilot production before transferring

it to a more expensive process

like injection molding for commercial

manufacture.

thermoforming to

improve and test a design and undertake

pilot production before transferring

it to a more expensive process

like injection molding for commercial

manufacture.

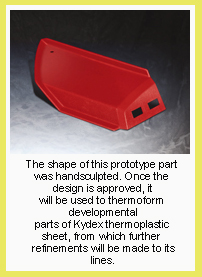

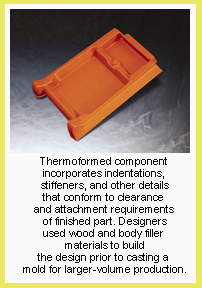

The sheet can also be thermoformed

into tooling at minimum

expense. Gidman Design has been

able to make up tooling, adequate

for 10 to 20 parts and sometimes

more, in its design studio and

model shop and repeatedly modify

it with simple wood and body-filler

materials to develop the shapes

needed for testing. From prototyping

it’s a simple step to thermoform

parts of Kydex sheet in quantities

of 50, 100 or into the thousands.

For higher volumes it is necessary

to have epoxy or reinforced

tooling made. Gidman says this

type of tooling can usually be fabricated

by casting resin into the back

sides of prototype parts made of

Kydex sheet rather than producing

patterns from drawings and complex

computer-aided design work,

an expensive and time-consuming

process.

As with any material, there is a

learning curve involved when working

with Kydex sheet. Its chemical

resistance, for example, means it

rejects most adhesives, so doublesided

tapes and glues need to be

used when attaching fasteners and

other hardware in applications like

seat parts and some types of covers

and shrouds. Finding the right thermoforming

temperature depends on

various factors like part shape, he

notes and requires trial-and-error

adjustments. Deep draws are achievable,

providing the shaping and

lead-up tooling is prepared appropriately

and according to how the

sheet behaves when formed,

Gidman adds.

For more information, contact

Richard Cort, Kleerdex Company,

LLC, 6685 Low Street, Bloomsburg,

PA 17815, 800-325-3133, Fax:

803-642-6867, E-mail: info@kleerdex.com, Web: www.kydex.com.

|