Often a variety of fabricating

operations take part in creating

a polycarbonate component

from sheet. What are the best

ways to obtain the desired sheet size,

drill and finish the final part? Here are

some recommendations to help optimize

these fabrication operations.

Smearing and welding of stacked

sheets are common problems related

to these saws. Band saws frequently

cause smearing at low speeds. Select

a blade with fewer teeth per inch to

minimize this problem. Scroll (jig)

saws with 10 teeth per inch provide

an average cut on a single sheet, but

stacked sheets will weld. A saber saw

with four teeth per inch will cut faster

than a scroll saw, but stacked sheets

will also weld.

Scribing And Breaking

Unless you’re working with gauges

of 0.060 inches or less, the practice

of scribing and breaking polycarbonate

sheet is not practical. The

force necessary to propagate the

notch is too high.

Shearing

Ordinary sheet metal shears can cut polycarbonate sheet

up to 0.125 inches thick at room temperature. A tight clearance

of 0.002 inches will avoid a rolled edge and burring in

the heavier gauges. Paper cutters and hand shears can only

be used in very thin gauges of sheet. Hot blade shearing is

not a good idea as it creates other problems.

Sawing Recommendations For Tuffak® Polycarbonate Sheet

|

Type of Cut |

Tool |

Blade Type |

Blade Parameters |

Blade Speed |

| Straight Cut |

Table circular

saw (panel

saw best for

sheet thicknesses

less

than 0.118

inches)

|

Carbide-tipped,

square and

advance tooth

|

60-80 teeth for

14 inch

Diameter

60-80 teeth for

10 inch

Diameter

0° rake angle

|

3,400 rpm |

| Curved Cut |

Band Saw |

STD Metal

Cutting |

10 teeth/inch

steel with

raker set

|

7,500 feet/

minute

|

| Curved Cut |

Saber or Jig Saw |

Metal Cutting |

10 teeth/inch

steel |

12,000 strokes/

minute |

Trimming and

Deflanging |

Router |

Carbide-tipped,

double or triple

straight fluted

|

1/2 inch diameter

5° positive rake

angle

|

18,000 rpm |

Industrial Lasers

Cutting polycarbonate sheet with a laser often produces

an edge having an amber or brown appearance. For this

reason, this procedure is not commonly used, although it

is gradually gaining acceptance.

Punching And Steel Rule Die Cutting

Sheet of 0.030 inches or less punches as clean as a

drilled hole. Punching thicker sheet may cause rolling and

burring. Use small clearances to reduce edge problems.

Cutting polycarbonate with a steel rule die is the best

high production method of creating finished shapes for

sheet up to 1/2-inch thick. An ordinary 4-pt steel rule die

cuts sheet up to 1/8-inch thick. More complicated heavier

dies require stronger backing and special ejection packing.

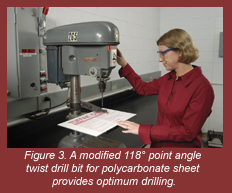

Drilling A Clean Hole

Use a standard 118 point angle twist drill bit for polycarbonate

sheet with the following modifications for optimum

drilling:

-

Grind a 10º back clearance at the cutting lip to eliminate

friction.

- Dub off the 12º positive rake at 0 so there will be a

scraping rather than digging action.

Without these modifications the drill will seize at any

speed or feed and cause gumming and smearing.

Additional drilling recommendations:

Additional drilling recommendations:

- Do not use a drill designed for acrylic sheet, which will

produce a burr at the exit edge of the hole.

-

Employ a medium feed rate (0.015 inch per revolution)

and slow drill speed (1,800 rpm) to produce the

best holes with the least stress.

-

Drill slightly oversized holes to accommodate mechanical

fasteners (Figure 3).

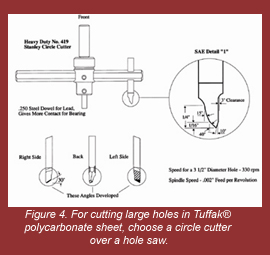

Making Large Holes

Do not use hole saws that will cause severe chipping and

smearing. Instead use a heavy-duty circle cutter (Figure 4)

such as Stanley No. 419.

This cuts a clean hole in polycarbonate

sheet when a predrilled 1/4-inch hole serves as

a lower bearing. The drill press must run true. For large

holes, use a slower spindle speed and a feed of 0.002

inches per revolution.

Routing And Jointing

For a good cut with no grabbing, use double and triple

straight-fluted router bits, 1/2 to 3/4-inch diameter, with a

10 back lip clearance and a positive rake angle up to 5º.

For an overhead router, select a spiral, four-fluted, carbide

end mill to produce a semi-polished edge. Slower feed rates

(3 to 4 inches per second) provide a superior finish. Choose

the end mill with a down-cutting action to prevent chatter.

Steel routers give a satisfactory edge but will not last. To

avoid heat buildup,

the spindle should run at 20,000 rpm.

Feed the sheet with a smooth, constant motion. In jointing,

especially, a smooth constant feed is paramount to a

good edge surface. Hold the polycarbonate sheet stationary

by clamping it tightly. Computer controlled routing

tables simplify cutting complex shapes in polycarbonate

sheet (Figure 5).

the spindle should run at 20,000 rpm.

Feed the sheet with a smooth, constant motion. In jointing,

especially, a smooth constant feed is paramount to a

good edge surface. Hold the polycarbonate sheet stationary

by clamping it tightly. Computer controlled routing

tables simplify cutting complex shapes in polycarbonate

sheet (Figure 5).

Finishing

You can finish holes in and edges of polycarbonate

sheet either by hand or machine. Use a light pressure to minimize friction from heat. Handle the sheet carefully to avoid

surface scratching.

Before polishing out scratches, sand the affected area to a final

600 grit. This minimizes buffing time and heat buildup, which

cause stresses that could later result in crazing.

Flame polishing often causes stress buildup from thermal

shrinkage during cooling. So it may make the polycarbonate sheet

more vulnerable to crazing. If you insist on flame polishing, anneal

the parts at 260°F for 45 minutes.

A glossy edge similar to the edge obtained with the discontinued

vapor polishing process can be achieved with an automatic

edge-finishing machine outfitted with a diamond-tipped

spindle (Figure 6). Carbide spindles will produce an edge with a

matte finish.

Clean polycarbonate sheet carefully because

your wiping action may grind dust into the surface,

scratching it. Use rubber gloves and splash goggles.

To remove stubborn dirt, first wipe with a soft

cloth saturated with a 5 percent solution of butyl

cellosolve, followed by soap and water.

Clean polycarbonate sheet carefully because

your wiping action may grind dust into the surface,

scratching it. Use rubber gloves and splash goggles.

To remove stubborn dirt, first wipe with a soft

cloth saturated with a 5 percent solution of butyl

cellosolve, followed by soap and water.

After you clean the sheet, you may notice a

deep, aging haze. If several mils deep, removal

may require a combination of sanding and polishing.

Yellowness is not just a surface phenomenon,

but is evenly distributed throughout the sheet.

Never use solvents to clean polycarbonate sheet,

except perhaps very mild solvents such as VM&P

naphtha, kerosene or isopropyl alcohol.

Written by Elizabeth Grimes, Senior Technical

Service Engineer for Atoglas, King of Prussia, PA.

For more information, contact

her at Atoglas, 2000 Market Street,

Philadelphia, PA 19103, 800-523-0762, Fax:

800-217-1486, Web: www.atoglas.com.

| Return Home | Back To Top |