|

RAPID MOLD TOOLS & FORMS

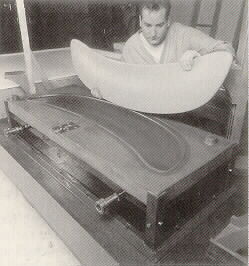

A revolutionary composite tooling system from a strategic partnership of two Michigan companies can cut specialized retooling times by as much as 50% with faster set-up and higher performance.

Matrix Composite Tooling Systems and Lenox Polymers have formed a joint venture to develop the Vestalloy Tooling System which produces molds in days as opposed to months while maintaining superior advantage in thermal conductivity and high operating temperature capabilities (more than 600°F).

Molds produced by Vestalloy require only a fraction of the time required to create molds manufactured by machined aluminum, cast aluminum, cast kirksite, and other laminated products. They are useable by vacuum and thermoformers, RIM, SRIM, resin transfer molding, compression molding, vacuum forming and stretch forming.

The companies are developing injection molding and blow molding capabilities which should be available in the near future. These will be capable of working with parts in polyurethane, ABS, polyolefins, nylon and fiberglass materials for applications in automotive, appliances, recreational boats and more. Molds are capable of producing high polished surfaces in addition to patterns both rough and fine.

For more information, contact Jeff Gniatczyk, Matrix Composite Tooling Systems, 28149 Kehrig Dr., Chesterfield, MI 48047, 810-949-8379, FAX 810-949-2051.

|