|

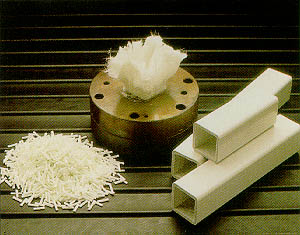

LONG FIBER EXTRUSIONS

Intek Plastics, Inc. has introduced Very High Modulus Extrusion (VHME), a breakthrough, extruded thermoplastic composite using Celstran(r) long fiber reinforced materials. Tough, chemically resistant, lightweight VHME is more durable and versatile than wood, metals, plastics and fiberglass. It is stiffer than most woods, more weatherable than pultrusions and will no corrode like metals.

During the past 15 years, long fiber materials have been used in injection molding applications. VHME thermoplastic composite is believed to be the first commercial application of long fiber extrusions.

A marketing study determined that VHME has potential use in more than 130 applications including wastewater and sewage treatment, corrosive environments, commercial refrigeration and transportation, office furniture, appliances and sporting goods, said Chris Zakashefski, Application Development Manager.

This new extruded composite is comprised of a Celstran long fiber-based core for strength and impact resistance with an inner and outer layer. These layers can be ABS, weatherable PVC or Polypropylene.

A key advantage of long fiber-based material is that it maintains its properties over a wide temperature range. Most notably, VHME's already outstanding impact resistance improves as temperatures drop.

Its heat deflection temperature of over 300° also makes it suitable where other plastics would typically soften.

One of the first commercial uses is as a replacement material for Apitong wood harvested from the rain forests in the Philippines. This extremely durable, but very heavy wood has been used in sub-floors of refrigerated semi-trailers.

It is 500 times less thermally conductive than aluminum. In another application, VHME is used to replace wooden drying racks in leather tanneries where drying temperatures exceed the boiling point of water.

For more information, contact Betty Drenckhahn, Intek Plastics, Inc. , 800 E. 10th St., Hastings, MN 55033-2299, 800-451-4544, 612-437-7700, FAX 612-480-5349.

|