|

UHMW ROLL COVERS - FIELD APPLIED

A new field-applied roll cover made of ultra-high molecular weight polyethylene (UHMW-PE), is expected to soon replace more costly rubber and fiberglass covers in the pulp and paper industry.

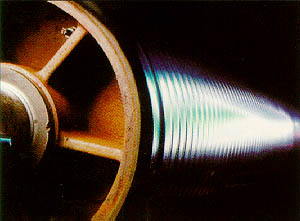

"This is absolutely the best wearing of all plastic materials, yet it has exceptional release properties," says Frank Chapman, Fluoron V.P. "Our new Fluoro-Wear(tm) UHMW-PE roll covers, which have similar release properties to Teflon(r) FEP, can be installed on site in an hour or so, using the same easy heat shrink process." Covers of UHMW-PE are now possible due to a new seaming technology which yields an almost undetectable seam.

The new roll covers were designed for rolls carrying felt and wire, and for other high wear situations. They are currently available in 20 and 60 mils, and in the same sizes as standard Teflon(r) covers (5" and up; up to 40' long).

For more information, contact Frank Chapman, Fluoron, Inc., Triumph Industrial Park, 505 Blue Ball Rd., Bldg. 120, Elkton, MD 21921, 410-392-0220, FAX 410-392-4357.

|