|

UNIQUE WELDING ROD

Have you ever lost a potential job because

you just couldn't fabricate what your client needed for the right price because

it was too difficult to weld? If you've ever had to weld plastic parts together

you will quickly realize that no available welding tool is capable of welding

everything you want, as fast as you want, where you want, as easily as you want,

as strong as you want, and for the price you want.

A company named Powercore International

Ltd. has the product that can link all the different welding tools together. The

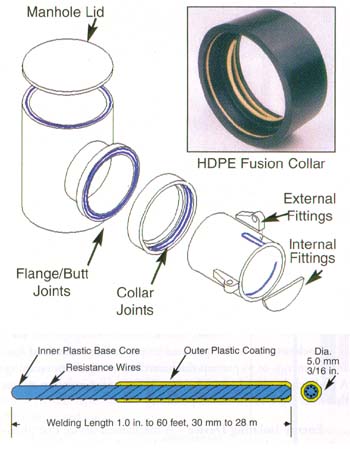

Powercore Plastic Welding System uses the same 3/16 inch (5mm) welding rod to

weld thin sheet, thick plate, pipe, molded parts of any size and shape in the

factory, or out in the field under dirty wet conditions. The system is not ment

to replace other welding methods, rather it can be used in conjunction with

them, and continue welding were they leave off.

The welding system has been used by many

different companies for some unique welding applications. Familian Plastics uses

it to fabricate all types of pipe fittings and parts for custom projects. Randy

Salsberry, Fusion Department Manager said, "Powercore allows me to solve

difficult welding problems, and the more I use it, the more applications I find

for it."

It is also used by Thermacor Process Inc.

to fabricate a unique split fusion coupling used to cover the joints on

insulated steel high pressure steam pipe (the steel joints are left exposed and

uninsulated to facilitate arc welding at the job site). Maskell Robins Ltd. has

a coupling for welding large diameter HDPE pipe together, and Corroseal Coatings

Ltd. of Sydney Australia welds underwater on dock pilings to create a protective

coating out of sheet material.

Powercore President Robert Pinder said,

"There are many potential industries that can use Powercore, but one of the

most exciting new industries is the fabricating of composite plastics, which are

difficult to weld with traditional methods."

Due to their unique way of heating parts

internally all at once, high puncture resistant, vacuum and thermo-formable

sheet material such as Twintex, a glass fiber/Co-polypropylene composite, are

now being welded together. Wytkin Designs Ltd. uses CMvT (Composite Mold Vacuum

Technology) to create parts with Twintex type materials, and president Andrew

Wytkin, said that "Powercore can be applied after the parts are made, or

included in the molding process to create a molded electro fusible parts."

He goes on to say that" this is especially useful when larger components

are being fabricated post forming or on site."

This type of fabrication of large

components utilizes some of Powercore’s other unique features, such as the

ability to make a long weld up to 60 feet in length in the same amount of time

it takes to make small welds and that more than one weld (or part) can be fused

at the same time. Depending on thickness of the part, weld times vary from 5 to

15 minutes, the shape and geometry of the weld has no effect on the time to

weld.

The system was first introduced at the 1991

Geosynthetics Conference in Atlanta Georgia. It was developed to solve a

particular HDPE sheet welding problem however, it quickly realized that the new

welding system could be used in many other types of welding applications.

Powercore Welding Rod, is an

"Electro-fusion System" made from a flexible thermoplastic rod

approximately 3/16" (5mm) in diameter with multiple super fine electrical

resistance wires wound inside, this allows the welding rod to be formed into

virtually any shape or configuration. The rod becomes an integral part of the

weld. The super fine wires remaining in the weld area have been extensively

tested, and have no negative effect on the strength or longevity of the weld.

The rod is an efficient and accurate heat source that can be placed exactly

where the parts need to be fused. It can be made form any thermoplastic material

that can be extruded, and is currently available in HDPE (black) HDPE (natural),

LLDPE (natural), Co-Polypro (natural), MDPE (yellow), and Nylon PA-12

(natural).

For more information, contact Robert

Pinder, Powercore International Ltd., 6-46 Antares Drive, Nepean, Ontario,

Canada K2E 7Z1, 888-367-2264, 613-226-3050, Fax: 613-226-3230, E-mail:

pcore@powercore.com, Web: www.powercore.com.

|