|

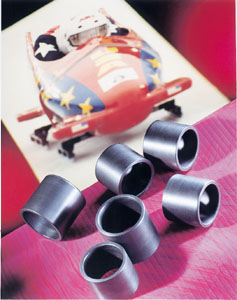

PEEK POLYMER SOLVES PROBLEM FOR U.S. BOBSLED TEAM

When the U.S. Bobsled Team competes in the

Olympics in Salt Lake City, getting down the ice faster than the competition is

what it's all about. The job of fine tuning the design of the 2 and 4-man

bobsleds belongs to Bob Cuneo of Chassis Dynamics. "We are constantly

scrutinizing ev ery aspect to achieve optimal performance," he says. "One area

where we have been experimenting with different materials is the shoe bushings.

We have finally found a material that has the potential to solve all our

problems." That material is VICTREX® PEEK(TM) polymer, a high performance

engineering thermoplastic.

Explaining the function of a shoe bushing,

Cuneo says that the "shoe" on a bobsled holds the steel runner which is the part

that runs on the ice. "The shoe rotates about an axle," he explains, "so it

needs a bushing. All the force of the sled riding on the ice goes through the

runner and through the shoe into the axle. Bobsleds experience loadings of 5 or

6 Gs through the bushings. For example, the 4-man bobsled weighs about 1100 Ibs.

with the crew in it - with 6 Gs, that's quite a lot of weight going through

these bushings."

According to Cuneo, manufacturers have used

bronze bushings in bobsleds for years but the pounding quickly loosened the

bushings and caused "play". After investigating several costly and/or high

maintenance options, they learned about the high performance characteristics of

PEEK(TM) polymer.

Several bushings were machined and put the

test. The polymer passed due to its ability to be machined and honed to very

tight tolerances and handle severe loads at zero clearances without grease. With

mechanics at times working 14 hours a day 7 days a week to keep the sleds

winning, they can now focus on other areas to get optimal performance.

For more information, contact Victrex

USA Inc., 601 Willowbrook Lane, West Chester, PA 19382, 800-VICTREX,

610-696-3144, Fax: 610-696-5702, Web: www.victrex.com.

|