|

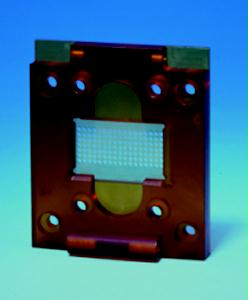

Enhanced Performance Low Stress Ultem® Slab

AL. Hyde Company has installed new process technology to produce a lower stress, better quality Ultem® slab product that is ideal for use in electrical/electronic, medical, and industrial applications. The material is an unfilled polyetherimide, made by G.E. Plastics, that is chemically resistant and displays excellent property retention and resistance to environmental stress cracking when exposed to most commercial automotive and aircraft fluids, fully halogenated hydrocarbons, alcohols, and weak aqueous solutions. Hyde's process improvements also enhance the physical properties of most filled grades of Ultem such as Ultem 2300, the 30% glass filled grade.

The properties include: high continuous use temperature; good chemical resistance; hydrolytic stability, high mechanical strength; low smoke generation; and dimensional stability. Ultem is FDA approved, inherently flame retardant, and multiple autoclavable. With their new process technology, the material can be easily machined, and it provides cost savings over ceramics in electrical applications. It also offers cost and weight savings over stainless steel in medical applications. Information on testing and physical property performance is available.

For more information, contact Bruce Dickinson, A.L. Hyde Company, 1 Main Street, Grenloch, NJ 8032, 856-227-0500, 800-234-HYDE (4933), Fax: 856-232-1754.

|