|

New Equipment Helps Abbott Plastics Stay Competitive

Improving quality while increasing output

is a never-ending challenge. The

dilemma is that high-quality commodities

often take too much time to produce.

One way to meet the challenge is by investing

in precision, high-yield equipment, but

how does a company justify new capital expenditures

in a depressed economy?

For

Abbott Plastics, the answer was simple –

by replacing inefficient CNC machining

centers with modern, new equipment, the

machines would pay for themselves.

For

Abbott Plastics, the answer was simple –

by replacing inefficient CNC machining

centers with modern, new equipment, the

machines would pay for themselves.

Abbott Plastics, an ISO9001/2000 certified

company, was founded in Rockford,

Illinois in 1980, as a distributor of industrial plastics. As manufacturing grew in the

area, Abbott expanded its services to

include the production of plastic parts. "We

have a diverse customer base, ranging from

manufacturers in the food industry to aerospace,"

explains co-owner Robert Nelson.

"Our customers need machined plastic

parts, because molding them is either too

expensive or not accurate enough."

Abbott initially used manual mills and

lathes to machine plastic parts. Then, in the

early 1990s, the company purchased its

first CNC equipment. The CNC machines

improved quality, but didn’t have much

capacity, and over the years, as demand

increased and competition grew, the

lack of capacity made it difficult for

Abbott to meet delivery schedules.

"We were looking to upgrade our

existing equipment to become more competitive," says

Britt Anderson, who oversees the machine shop. "From

my previous experience as a shop owner, I found that

Haas gave me the best value for the dollar. There were a

lot of machines at the same price and capacity, but when

I asked people about their machines, they weren’t happy

with the service they were receiving. From my experience

with Haas, I knew that service and reliability would never

be an issue."

Abbott purchased a Haas

VF-4 vertical machining center

in 2001, and then added

a VF-3 and another VF-4 a

year later. "We replaced four

older machines with three

Haas machines, and we still

increased our capacity,"

says Nelson. "The Haas

machines increased our

product flow and improved

our quality by weeding out

inefficiencies."

Even with the increased capacity, however, Abbott still

was unable to bid on certain jobs. Plastic comes in all different

shapes and sizes, and Abbott had been doing a

brisk business cutting parts out of flat sheets. But the one

router they had was limited by its size and difficulty of use.

"We needed another router to keep up with the demand,"

says Nelson. "We had one that was four by eight feet, but

we thought we could do more if we had a bigger machine."

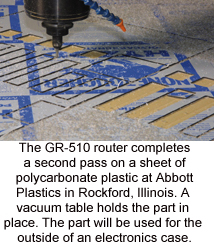

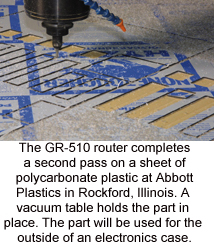

Abbott didn't have to look far to find the right machine.

They saw the Haas GR-510 Gantry Router at IMTS in

Chicago and liked what they saw. "It was the machine we

needed, and we took delivery of one soon after the show.

Then we had to work fast to get the machine up and running,

because we'd already promised people products,"

says Anderson.

"The gantry’s five-foot-by-ten-foot

table is perfect for us, because the plastic

sheets come in ten-foot-long pieces,"

says Nelson. "We were trying to

machine ten-foot sheets on our other

router, and it took a lot of extra time

and effort. With the GR-510, we've eliminated

the waste of time and materials."

Training on the new machine was

fast as well, notes Anderson, because

the GR-510 has the same user-friendly

control as the other Haas machining

centers in the shop. "Our other router

has a PC-based control," he says, "and

I only have one guy who can run it; it's

an animal of its own. But the GR-510

has the same control as our other

Haas machines, so now I have five dif-ferent

guys who can run it."

The machine’s rigid tapping feature

was another benefit to Abbott

Plastics. "We now run parts on the

Gantry that previously we could only

run on one of the mills," Anderson

says. "We can do parts on the GR-510

that we never would have thought of

running on our other router.

Nelson agrees, adding, “When you

have a machine with capacity like

this, you start thinking of all the different things you can do to

save time. It has given us

the capacity we need, and

allowed us to look at work

that we couldn’t have been

competitive on a year ago.”

Abbott has used the GR-510

to cut plastic sheets up

to 4 inches thick, and is

already looking for more

ways to use it.

By investing in new equipment,

Abbott Plastics not

only increased their productivity, but also reduced labor

costs, allowing them to keep prices competitive despite

increased material costs. With their old machines, says

Nelson, “we had 20 people on two shifts. Now, we no longer

require a second shift. We have fewer machinists in the shop,

and yet, we’re still getting more output. We’ve done studies

where we look at how much time it used to take us to run a

job, and we compare it with how long it takes now on the

Haas machines,” Nelson continues. “We’ve had a sixty percent

increase in productivity over the other equipment.”

Quality has improved as well, says Anderson. With the old

machines, “We discovered that the guys were taking short-cuts

to meet production deadlines, because they couldn’t get

the machines to do what they needed. Now, the Haas

machines are able to do what we need, and with better accuracy.

We used to have to do a final inspection on parts, but

the new machines are so accurate that we’ve eliminated the

final, and now we just use in-process inspections.

Give people the right equipment and they often become

better, more productive employees. That has definitely

been the case at Abbott Plastics. “Our ability to machine

parts has improved. The guys in the shop have gone up

two tiers in their knowledge and their ability to machine

parts,” says Anderson.

As a result, Abbott is better able to meet production

schedules and respond quickly to emergencies. “Our

deliveries are much better,” says Nelson. “We usually take

about three weeks, but if someone requests something

special, we can turn it around in a day.”

With the capacity problems solved on the milling side

of things, Anderson looked next to replacing one of the

shop’s turning centers. “We needed the capacity to run

larger diameter parts without the need to chuck

blanks,” he explains. “We were wasting a lot of time and

material with our old lathe, because we had to cut

blanks and load them individually.” A Haas SL-30 lathe

with Big Bore option and tailstock solved the problem.

The Big Bore option increases the normal bar capacity

from 3 inches to 4 inches, while the tailstock provides

support for longer pieces of plastic. “Now, we can run

jobs from a continuous length of rod up to five feet

long,” Anderson says.

Now that Abbott Plastics has invested in the right

machine tools and is reaping the benefits of increased

capacity, superior accuracy and better machinists, the

company continues looking for additional ways to maintain

a competitive edge. “I just finished taking a manufacturing

course on Six Sigma, and the goal is to improve

processes. So I’m trying to spread that thinking around

the shop,” says Anderson.

Story and photos by Scott Weersing, Haas Automation, Inc.

|