|

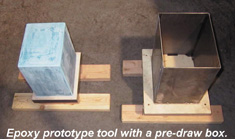

THERMOFORMING: Thermoforming Molds

From epoxy tools on

single stations to

water-cooled aluminum

tools on three station

rotaries and four station

twin sheet pressure

formers, cut-sheet

thermo-formers

require a wide

variety

of molds for the parts

and products they produce.

There is no standard type

of material from which

molds are manufactured.

With low pressure and/or

low volume applications,

wood or epoxy molds may

be acceptable, whereas

with high pressure and/or

high production applications,

cast or machined aluminum

molds with temperature controls

would usually render

the best performance.

Before forming a new part,

the thermoformer must consider

several criteria in order

to determine which mold

material is best for the job.

What type of plastic material

will be formed? What

forming technique will best

suit the product? Will it

require a male or female

mold? What is the amount

of production required

from the mold? Is the

finished product too

complex for simple

mold materials? Does

the overall part size

justify an expensive

mold material or does

the parts configuration

change from year to

year? These are just a

few of the factors to

consider before

determining which type

of mold material to utilize.In addition to selecting the best material, thermoformers

must then determine shrinkage rates for the different

types of thermoplastic materials they will be forming.

They must also determine whether or not the mold must

be temperature controlled, or even multi-zoned temperature

controlled.

Cut-sheet thermoforming machinery suppliers should work

with the thermoformer to develop and design their

machinery and/or sequencing of their machinery based on

a customer’s specific mold and its characteristics.

Cut-sheet thermoforming machinery suppliers should work

with the thermoformer to develop and design their

machinery and/or sequencing of their machinery based on

a customer’s specific mold and its characteristics.

With the machinery manufacturer involved, cycle times

(parts per hour) can be guaranteed, along with a proven

timed forming sequence

and a finished

product that meets the

specification. This is

usually accomplished

concurrent within the

machinery build time.

Machine, mold and

part approval can then

be done concurrently at

the machinery manufacturer

at time of training.

This has become

more and more popular

with clients because it

eliminates the very

costly and very timely learning curves that come with new

machinery, new tooling, new material and new sequencing.

Written by Michael P. Alongi, Sales Director for MAAC

Machinery Corp., manufacturers of a wide range of cut-sheet

thermoforming machinery.

For more information, contact MAAC Machinery Corp., 590

Tower Blvd., Carol Stream, IL 60188, 630-665-1700,

Fax: 630-665-7799, E-mail: sales@maacmachinery.com,

Web: www.maacmachinery.com.

Pictures provided by: Thermoform Tooling Works Carol Stream, IL

|