|

ROUTING: Routing Polycarbonate

Polycarbonate

was commercially

developed

in the 1950’s,

and has proven to be

a versatile material

for use in the plastic

fabrication industry.

Thermoformers and

sheet fabricators utilize

polycarbonate for

a variety of applications

because of the

outstanding impact

strength and excellent

machining characteristics

of the

material.

Tooling

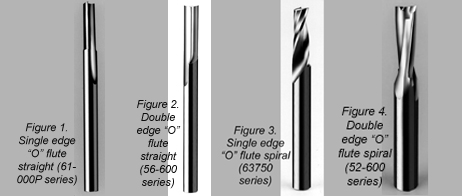

In terms of routing, polycarbonate can best be categorized

as a soft plastic. This necessitates the use of “O”

flute tools, which are distinguished by a half moon design

in the face or flute area of the router bit. These single- and

double-edged tools are manufactured from high-speed

steel for hand fed applications, and solid carbide for CNC

machinery. The high-speed steel material is only available

in straight flute configuration, while the solid carbide

material utilizes

straight and spiral

flute geometry. The

choice of straight or

spiral flute router bits

depends greatly on

how the user wants

to influence the chip.

A general rule to follow

regarding influencing

the chip is to

use “O” flute straight

or downcut spirals on

thermoformed parts

where lifting the part

can be problematic.

Sheet fabricators on

the other hand are

more concerned with chip removal, and should employ

upcut spirals with “O” flute geometry to adequately

remove chips from the workpiece. These general recommendations

can be further quantified by visiting

www.plasticrouting.com. This website, sponsored by

Onsrud Cutter, provides specific tool recommendations

based on a variety of information from manufacturers

offering polycarbonate material.

After the proper tool has been selected, there are other

considerations including rigidity and of course, programming

for the CNC user to provide a successful

routing operation. The tool selection

process can be for naught, if proper

techniques are not followed in the above

areas.

Rigidity

Rigidity is key regardless of hand fed or

CNC applications. Rigidity applies equally

to the machine itself and to the fixturing of

the components to be routed. Machine

rigidity for hand fed applications where

electric or air routers are employed mostly

involves the maintenance and replacement

of the collet system. However, the air

router requires the replacement of bearings

and spindle vanes on regular intervals

to maintain rigidity. Also, the air router

must have a minimum of 90-PSI air pressure

to maintain horsepower and it must

utilize properly toleranced tools to insure

rigidity. In CNC routing, properly lubricated

and maintained machine slides and drive

systems are essential to optimizing feedrates

and productivity. Preventative maintenance

of CNC routers is critical to long

term operation where part surface finishes

are critical.

While machine rigidity is critical to consistent

performance, fixturing is equally

important to the surface finish

on each machined part.

Fixtures should be rigidly

built and mounted to the

work surface. Vacuum supply

should be oversized

whenever possible and hard

fixturing should be securely

mounted without opportunity

for movement. When

dealing with 5-axis fixtures,

unsupported edges should

be minimized and vacuum

distribution should be maximized

at the cut area. Also,

friction enhancements such

as rubberized coatings and

gasketing sheet foam may

be utilized.

Programming

Once the tool selection

process has been finalized

and all facets of the operation

are rigid, programming the feed and speed along with

the tool path becomes paramount. The feed and speed of

the machine not only dictates cycle time, but it dictates the

creation of chipload. Chipload is the

actual thickness of the chip and is influenced

by the feed, speed and number

of cutting edges on the router bit

(Chipload = Feedrate/RPM x # Cutting

Edges). The optimum chipload to

achieve the best finish seems to be in

the range of 0.004 to 0.012. In the

case of polycarbonate or a soft plastic,

this provides the best finish by properly

curling the chips during the routing

process. The website www.plasticrouting

.com, not only provides tool selection,

but also quantifies feed and speed and

thus proper chipload for a variety of

polycarbonate materials.

Another important programming

feature is the choice of tool or feed

direction. In machining, there is climb

cutting and conventional cutting. In

most cases, conventional cutting provides

a better part, but the user

should always compare the finish of

the scrap to the finished part to identify

which edge is better. If the scrap is

better, reverse the cut direction.

Cutter entry and scrap can be particularly

problematic in routing plastic.

Plunging directly into the part gives no

path for chip removal and can cause

chip wrap, deformity or melting chips to the part. This can

be avoided by programming

the machine to

enter the part from the

side or ramp into the

part, thus providing a

path for chip removal and

avoiding all the problems

mentioned with plunging.

Scrap should be minimized

to avoid part ejection,

vibration, poor finish

and quite possibly, tool

breakage.

Polycarbonate is relatively

easy to machine

when the proper tool is

selected and good routing

practices such as rigidity

and proper programming

is utilized.

For more information, click on the Author Biography link at the top of this page.

|