|

THERMOFORMING: Emerging Markets in Thermoforming

The cut sheet thermoforming market is improving

rapidly. Many new markets are being created and

applications that were not possible or feasible in

the past are now being innovated, offered and in some

cases demanded!

These improvements and new markets are being driven

by several recent advancements in material, material processing,

more advanced thermoforming equipment, more

elaborate tooling and of course our industry’s ever growing

creativity and determination.

As new applications are discovered and implemented it

is difficult for every thermoformer to be aware of all the

technical advancements. Manufactures must continually

learn from different markets and utilize or apply new technologies.

As the market appears to be running at full

speed we will briefly explore some of the newer markets

or developing markets in the current generation of thermoforming

technology.

Paint Films & Decorative Films

Paint films and decorative films continue to gain rapid

recognition in the marketplace. The thermoformed product

starts with a sheet that is produced by laminating or

co-extruding a paint or decorative film onto a heavier

gauge sheet (ABS, TPO, Polycarbonate, etc.).

These films

are eliminating the need for painting and/or decorating,

as well as creating new opportunities to replace more

expensive materials or processes.

These films

are eliminating the need for painting and/or decorating,

as well as creating new opportunities to replace more

expensive materials or processes.

Wood grain, stainless steel, aluminum, carbon fiber and

even chrome finished laminates are allowing thermoformers

to manufacture products

that have the features and

benefits of plastic, but still

maintain the same appearance

as the material they are

replacing. Laminated wood

grain materials are being

used where wood appearances

are required, from

automotive interior trim to

hot tub or spa cabinetry.

Stainless steel and aluminum

laminates are replacing high

cost metal products in automotive

as well as in the appliance

enclosure industry. Chrome laminates are replacing

heavier, chromed metal products like vehicle bumpers,

grills and emblems.

What we refer to as paint films, are films and resins that

have been able to achieve a “Class A” automotive quality

finish. Meaning processors can eliminate the need to

paint products after they are formed. Most popular in

automotive exterior parts in the low to mid volume vehicles,

these materials offer huge savings when compared to

the costs of other processes that require establishing an

entire painting process. As the paint films continue to gain

popularity in automotive, these films will also start to find

their way into other market places that require similar

high quality, paint-like finishes.

Foams

From new thermoplastic foam sheet and pre-shaped

rigid foam inserts, to secondary liquid foam, thermoformers

and foam suppliers are continually developing innovative

ways to incorporate foam based materials with thermoformed

parts. Although foams have been used for quite

some time in the thermoforming process, new foam materials

and new foam innovations and applications are pushing

thermoformed product uses to new heights.

New advances in foam sheet materials are allowing

thermoformers to expand their capabilities. Foams are

being used for comfort in shoe insoles, for sound absorption

in interior vehicle applications, as well as for lighter

weight and even moisture resistant reasons (like used in

automotive ventilation systems). Products that must be

light weight, soft and have little rigidity requirements all

lend themselves to thermoforming foam based sheet.

When rigidity is a key factor, twin sheet forming is allowing

processors the ability to insert pre-shaped rigid foam

in between two formed cavities allowing for a stronger

more secure product. Floatation devices, plastic pallets

and doors are all being made utilizing this process. In

many cases the foam allows the end product to be made

with thinner sheet gauges by allowing the foam to act as

the major structure and reinforcement, rather than the

thickness of the plastic sheet. It can also help reduce the

finished products weight when utilizing foams rather than

thicker sheets or other fillers.

In single sheet forming and pressure forming,

different types of pre-shaped rigid foam inserts are

also being used for product reinforcement. Since

we are not inserting foam between two sheets but

rather just to one side, pressure is being utilized to

adhere the pre-shaped rigid foam to the thermoformed

part just subsequent to vacuum forming.

This technology is allowing manufacturers to eliminate

the costly secondary foam operations as well

as any type of gluing operation.

Substrate Forming/Vinyl Wrapping

The automotive interior market is by far the

biggest consumer of these products, but with the

ever changing demands in automotive, a lot of new

opportunities are being created with this technology

in and out of the automotive world.

Substrate forming or vinyl wrapping consists of

heating vinyl and forming it over a pre-glued (heat

activated) rigid substrate. Once vacuum formed the

hot vinyl sheet activates the glue and adheres to the

substrate. The substrate can be made from a variety

of different materials and or processes but typically

depends on the volume. Lower volume substrates

can be a rigid thermoformed part, or even

fiberglass, whereas in most automotive applications

higher volume substrates are injection molded.

As these applications make their way into the

contract manufacturers’ facilites we are beginning

to see this same technology starting to be

applied outside of the automotive interior market.

All mass transportation methods can utilize

this technology; buses, trucks, RVs and trains,

the soft touch leather-like appearances add a

higher quality part making final products more

attractive and appear higher end looking. In

addition to transportation markets, this technology

is replacing many other leather wrapping

applications, like seat coverings, armrests and

even custom carrying cases.

With these opportunities, new manufacturers

and new suppliers are working together to develop

new methods and improvements to accommodate

better processing methods.

Screen Printing/Distortion Printing

Screen printing or distortion printing onto raw sheet

stock, then thermoforming it into a 3-D product, has been

somewhat of a niche market in thermoforming. New technology

is allowing more companies to expand their offerings

into this area. Most popular in the display, sign and

point-of-purchase industry, screen printing sheet and

forming it has traditionally taken an extensive knowledge

of both processes to be efficient and profitable. This

knowledge was derived from experience and trial and

error.

Today, new companies or inexperienced thermoformers

can easily and quickly take on these projects thanks

to new proprietary software and processing developments.

Thermoformers are now able to create

these products by utilizing virtually the same standard

job procedures they traditionally use. Once

the part is designed and molds have been made,

the thermoformer only has to run a few sheets with

grids on them and record their machine settings (so

they can run production using these same settings).

The now formed blank sheets can be digitized and

processed through custom software which will determine

the proper distortion printing parameters.

Once printed,

manufacturers

can set up

the machine

as they did

for the sample

run and

create a

quality part

on the first

shot, therefore

eliminating

the learning

curves as

well as the

entire trial and error process typically associated

with the graphic printing. This new software basically

turns a difficult, time consuming distortion

thermoformed project, into a straightforward

affordable vacuum formed part.

Larger Parts

Large part thermoforming is nothing new but

manufacturers and OEMs are gaining confidence

and are proceeding to replace many large products

that have previously been made in more expensive,

slower and more labor intensive processes.

In the past, low volume requirements have made

it too costly to thermoform some large products.

Today some OEMs and end users are finding ways

to increase volumes not only through increasing

sales but by standardizing some of these larger

products. By standardizing, manufacturers can justify the

costs associated with large part thermoforming and maintain

much more consistency and repeatability.

Large fiberglass products are steadily being converted

over to thermoforming; from boat hulls, to large bus,

truck, tractor and RV parts. Water drainage systems, holding

tanks and other products related to new construction

business are also gaining popularity and are being produced

in larger volumes. With more and more companies

investing in large machinery capable of forming these

products, new applications and new markets will continue

to develop even further.

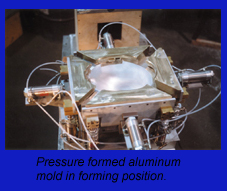

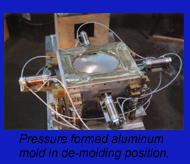

Pressure Forming &

Twin Sheet Forming

Pressure Forming and Twin Sheet Forming continue

to gain popularity and are becoming much more

recognized. Consumers are demanding better aesthetics

and more design features in their products

that the traditional thermoforming process cannot

offer.

Many thermoforming manufacturers are quickly

adapting to have true pressure and twin sheet

capabilities by either purchasing new machinery

along with its new technology or by establishing relationships

with other companies who already have

these capabilities.

Many thermoforming manufacturers are quickly

adapting to have true pressure and twin sheet

capabilities by either purchasing new machinery

along with its new technology or by establishing relationships

with other companies who already have

these capabilities.

As this technology matures throughout the industry,

manufacturers are becoming more aware of what

these two processes can add to their current product

offerings. Even companies who have had these capabilities

are learning more from their machine and

mold manufacturers on how far these processes can

be taken. As new applications develop, new technology

will continue to develop with it. Never before have

we seen such creativity in mold designs.

Molds with

moving pieces, undercuts, flippers and hinges are

becoming somewhat common, rather than specialty

projects. Today’s pressure forming market has room

to grow, and mold design and capabilities will continue

pushing out better products more efficiently.

“Pressure formed aluminum mold in forming position”

“Pressure formed aluminum mold in de-molding position”

Molds with

moving pieces, undercuts, flippers and hinges are

becoming somewhat common, rather than specialty

projects. Today’s pressure forming market has room

to grow, and mold design and capabilities will continue

pushing out better products more efficiently.

“Pressure formed aluminum mold in forming position”

“Pressure formed aluminum mold in de-molding position”

These applications and new markets are all being driven

by the improvements our industry is making in materials

and machinery. They stem from a combination of straight

creativity, finding solutions to product sophistications and

the customer demanding more for less. From reducing costs

and adding strength and longevity, to increased functionality,

today’s thermoformers will continue to develop new applications

for replacing wood, metal, fiberglass, glass or just

replacing other plastic processes. Today’s thermoformers

are proving the processes wide range and flexibility.

Consumer confidence is increasing and the new advances

being made are opening more doors to today’s thermoformers

and their customers.

Written by Michael P. Alongi, Sales Director for MAAC

Machinery Corp., manufacturers of a wide range of cutsheet

thermoforming machinery.

For more information, contact MAAC Machinery

Corp., 590 Tower Blvd., Carol Stream, IL 60188, 630-665-

1700, Fax: 630-665-7799, E-mail: sales@maacmachinery

.com, Web: www.maacmachinery.com.

|