|

NPE Preview

NPE 2006: The International Plastics Showcase will

take place from June 19 to 23, 2006 at Chicago’s

McCormick Place exposition center and will be the

largest international plastics show of the year. Founded and

sponsored by the Society of the Plastics Industry, Inc. (SPI), the

triennial show will be the 25th NPE since 1946. At least 2,000

companies are expected to exhibit on more than 1,000,000

square feet of space, one-third of them coming from outside the

U.S.A. Visitors from more than 100 countries will attend.

Among the exhibitors at NPE 2006 will be virtually all

of the world’s major suppliers of primary processing and

auxiliary equipment; machine and mold components and

supplies; resins and compounds; additives, fillers and reinforcements

and moldmaking services.

Throughout the show there will also be extensive

exhibitor representation in several categories including:

custom processing: companies that compound, mold,

extrude, thermoform and recycle; e-commerce; fabricating

and assembly: adhesives, fasteners, machining equipment,

cutters and welders; post-extrusion: systems for pipe, profile,

flat film and sheet, blown film, wire and cable.

The following companies will be exhibiting at NPE 2006

this June 19 to 23.

For additional information on NPE

2006 visit their website at www.npe.org.

Specialty Tools

Abbeon Cal, Inc. is the publisher of the PlasticWorking

catalog and has been providing specialty tools and

instruments to businesses since 1946. In addition,

Abbeon is the U.S. supplier for the German manufacturers

of FORSTHOFF Hot Air Tools, A-Z Formen Thermocutters,

Lufft Precision Instruments and Trotec Moisture Meters.

Abbeon offers an iron-clad money back guarantee on all

their products and if you can’t find what you need in their

catalog or on their website, they will either find it or build

it for you.

For additional information, contact Bob Brunsman,

Abbeon Cal, Inc., 123 Gray Avenue, Santa Barbara, CA

93101, 800-922-0977, Fax: 805-966- 7659, E-mail:

abbeoncal@abbeon.com, Web: www.abbeon.com. NPE

Booth #11305

Welding Rod

Drader Manufacturing

recently invested in new equipment

and technology to augment its plastic welding

wire business.

The new equipment increases their capacity

and the new technology allows

them to maintain even tighter tolerances

during rod production. Drader

stocks a range of welding rod and custom

manufactures numerous colors

and types of plastic. Customers can

send their own resins to ensure the

welding rod matches the parent plastic

material exactly. Drader’s minimum

order remains 10 pounds. Their welding

rod can be used with most fabrication

type plastic welders on the market

today.

The new equipment increases their capacity

and the new technology allows

them to maintain even tighter tolerances

during rod production. Drader

stocks a range of welding rod and custom

manufactures numerous colors

and types of plastic. Customers can

send their own resins to ensure the

welding rod matches the parent plastic

material exactly. Drader’s minimum

order remains 10 pounds. Their welding

rod can be used with most fabrication

type plastic welders on the market

today.

Injection Welder

Drader is also the manufacturer of

the Injectiweld for fabricating,

prototyping and repairing thermoplastics.

The welder is easy to use and produces

high quality welds.

Two unique features set the Injectiweld

apart from other plastic welders.

A hot tip melts into the parent material eliminating the need to scrape off the

layer of oxidation before making a

weld. Interchangeable tips increase

the welder’s versatility,

allowing welds ranging in

size from 1/16” to 1/2” in

a single pass. The second

feature is its automatic feed system.

This allows control of the welder with one hand and

use of the other hand to hold the part being welded. High

quality welds are produced because the unit injects a

molten shot of welding rod into the weld zone with consistent,

repeatable pressure.

A hot tip melts into the parent material eliminating the need to scrape off the

layer of oxidation before making a

weld. Interchangeable tips increase

the welder’s versatility,

allowing welds ranging in

size from 1/16” to 1/2” in

a single pass. The second

feature is its automatic feed system.

This allows control of the welder with one hand and

use of the other hand to hold the part being welded. High

quality welds are produced because the unit injects a

molten shot of welding rod into the weld zone with consistent,

repeatable pressure.

For additional information, contact Bruce Lecky, Drader

Mfg. Ind., Ltd., 5750 50th Street NW, Edmonton, Alberta

T6B 2Z8 Canada, 800-661-4122/780-440-2231, Fax:

780-440-2244, E-mail: blecky@drader.com, Web: www.drader.com. NPE Booth #9755

Tap Plastic

Do your tapping on the FlexArm as a secondary operation.

The FlexArm saves money by utilizing the operator’s

idle time and reducing the machine cycle time. Units

are available up to 2” tap capacity with quick change

chuck system. Blind holes in soft plastics can be tapped

without stripping the threads

by adding an Automatic

Depth Stop to the FlexArm.

Do your tapping on the FlexArm as a secondary operation.

The FlexArm saves money by utilizing the operator’s

idle time and reducing the machine cycle time. Units

are available up to 2” tap capacity with quick change

chuck system. Blind holes in soft plastics can be tapped

without stripping the threads

by adding an Automatic

Depth Stop to the FlexArm.

For additional information,

contact Dan Sudhoff,

FlexArm, 851 Industrial

Drive, Wapakoneta, OH

45895, 800-837-2503/ 419-

738-8147, Fax: 419-738-8140, E-mail: flexarm@flexarminc.com, Web: www. flexarminc.com. NPE Booth

#5480

5-Axis CNC Line

MAAC Machinery and Stopol will be showing a new line

of 5-axis CNC routers for the thermoforming industry.

The Royce Router offers faster feeds and speeds, high quality

and reliable components. The router combines the latest

technology and speed to improve cycle times up to 400%.

Through a joint partnership between MAAC and Stopol,

the Royce Router line has been created to meet the

demanding needs of today’s heavy gauge thermoformers.

The router is designed specifically for the maximum production

of thermoformed parts. Mass production of a single

model will deliver the maximum value at the most

cost-effective price.

Cut-Sheet Thermoforming Line

MAAC has recently implemented several new features

to its line of thermoforming machinery. All machines

have larger mainframes and platen structures. Platen and

index speeds are almost double those of previous models.

New programming developments have upgraded the

System 9000 control system to provide massive amounts of

control. Each function of the machine can be set and saved

into the controller. This allows every machine parameter to

be activated with the push of a button for precise repeatability

and the quickest setups.

For additional information, contact Michael Alongi,

MAAC Machinery Corporation, 590 Tower Blvd., Carol

Stream, IL 60188, 800-588-MAAC/630-665-1700, Fax:

630-665-7799, E-mail: sales@maacmachinery.com,

Web: www.maacmachinery.com. NPE Booth #4216

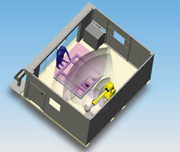

Robotic Trimming

Robotic Production Technology (RPT) will introduce the

latest addition to its family of standard router trimming

systems, the RoboTrim™ RT-500, at NPE 2006. The

RoboTrim RT-500 is a new pre-engineered router trimming

and knife deflashing

system designed specifically

for the plastics

industry. The RT-500’s

increased part height

capability gives customers

the flexibility to

process a variety of part

sizes and shapes. The system’s

speed and reliability

result in more uptime

and higher throughput to consistently deliver more parts

per hour than other trimming methods.

systems, the RoboTrim™ RT-500, at NPE 2006. The

RoboTrim RT-500 is a new pre-engineered router trimming

and knife deflashing

system designed specifically

for the plastics

industry. The RT-500’s

increased part height

capability gives customers

the flexibility to

process a variety of part

sizes and shapes. The system’s

speed and reliability

result in more uptime

and higher throughput to consistently deliver more parts

per hour than other trimming methods. The RT-500 is

designed to remove the operator from the trimming area,

resulting in a safe and ergonomic operating environment.

The system is mounted on a single base plate and

designed for quick installation and start-up.

The RT-500’s riser-mounted robot and servo-controlled

rotating table allow it to easily process 60” x 60” x 36”

high parts typical of thermoformers. Longer parts of up to

80” x 36” with shorter heights can also be processed.

For additional information, contact Roberta Zald,

Robotic Production Technologies, 1255 Harmon Road,

Auburn Hills, MI 48326, 248-829-2800, Fax: 248-829-2750, E-mail: solutions@rpt.net, Web: www.rpt.net or Cathy Powell, FANUC Robotics America, Inc., 3900 West

Hamlin Road, Rochester Hills, MI 48309, 800-47ROBOT/248-377-7570, Web: www.fanucrobotics.com.

NPE Booth #9620

New Shredder Technology

VECOPLAN LLC , a leading manufacturer of industrial shredding

equipment, plans to exhibit and demonstrate

many new product lines at NPE 2006, including its new

HiTorc™, SureCut™ technologies and VH-series™ Horizontal

Shredders and Granulators.

VECOPLAN shredding and recycling equipment is used

in many industrial applications in the plastics processing

and reprocessing industries, woodworking industries,

printing and converting industries, secure destruction

industry, general waste processing and recovery industries.

For additional information, contact Mark Craver,

VECOPLAN, LLC, P.O. Box 7224, High Point, NC 27264,

336-861-6070, Fax: 336-861-4329, E-mail: info@vecoplanllc.

com, Web: www.vecoplanllc.com. NPE Booth #9601

Welding Equipment

WEGENER Welding, LLC offers a comprehensive line

of welding equipment and accessories for the thermoplastics

fabricator including: hot gas (air) welders from

single units for repairs or production to full, comprehensive

systems; extrusion welders in small, medium or high

output for sheet, piping or lining applications; semi-or

fully-automatic sheet butt welding or bending equipment

and AC and DC spark testers for pinhole detection in plastic

welds or non-metallic coatings.

Wegener’s philosophy is to assist the customer in evaluating

their needs. Education is an important factor. The

Wegener staff is DVS (German Welding Association) certified

and offers DVS certified training.

Wegener can also design and build custom machinery

for very specific applications.

For additional information, contact Dagmar Ziegler,

WEGENER Welding, LLC, 16W231 S. Frontage Road, Ste.

12, Burr Ridge, IL 60527, 630-789-0990, Fax: 630-

789-1380, E-mail: info@wegenerwelding.com, Web:

www.wegenerwelding.com. NPE Booth #9064

The following exhibitors offer machinery and tooling for plastic sheet fabricators and thermoformers

| Exhibitor |

Booth |

Website |

| Abbeon Cal Inc. |

11305 |

www.abbeon.com |

| Advanced Ventures in Technology |

9404 |

www.adv.ven-tech.com |

| Brown Machine LLC |

1409 |

www.brown-machine.com |

| Drader Injectiweld, Inc. |

9755 |

www.drader.com |

| FlexArm |

5480 |

www.flexarminc.com |

| Leister Process Technologies |

6358 |

www.leister.com |

| MAAC Machinery |

4216 |

www.maacmachinery.com |

| Plastic Welding Technology |

9916 |

www.pwtworld.com |

| Robotic Production Technology, Inc. |

9620 |

www.rpt.net |

| Stiles Machinery |

9762 |

www.stilesmachinery.com |

| Thermwood Corporation |

9210 |

www.thermwood.com |

| Vecoplan, LLC |

9601 |

www.vecoplanllc.com |

| WEGENER Welding, LLC |

9064 |

www.wegenerwelding.com |

|