|

SPE Preview

The 16th Annual SPE Thermoforming Conference

and Exhibition will host over 1,000 attendees and

nearly 100 exhibitors at the Nashville Convention Center

in Nashville, Tennessee, September 16-20, 2006. This

show will be a forum for the newest techniques, latest

equipment, materials, auxiliary equipment and current

industry news. The conference will also feature multiple

technical sessions targeting roll-fed and cut-sheet thermoformers.

The following companies will be exhibiting products

for cut-sheet thermoformers. For information and

registration visit www.4spe.org.com.

Expanded Product Line

Advanced Ventures in Technology,

Inc. (AVT) has

expanded its newest thermoforming

machinery automation

system offerings.

AVT has

introduced a new state-of-theart

pick and place sheet load

and unload system whereby material is lifted from a stack

with vacuum cups, rotated 90º and placed on a shuttle

conveyor; then the sheet is shuttled out, then shuttled

back on a reversing conveyor; a pick and place system

then picks the sheet up once again, rotates it back 90º

and places it back on the stack. The system is said to

increase production by as much as 30%.

AVT has

introduced a new state-of-theart

pick and place sheet load

and unload system whereby material is lifted from a stack

with vacuum cups, rotated 90º and placed on a shuttle

conveyor; then the sheet is shuttled out, then shuttled

back on a reversing conveyor; a pick and place system

then picks the sheet up once again, rotates it back 90º

and places it back on the stack. The system is said to

increase production by as much as 30%.

AVT, a designer and manufacturer of rotary and single

station pressure thermoforming machines, also sells custom-

made automation systems for all types of thermoforming

equipment. AVT built and installed the world’s

largest rotary thermoforming machine, an automated 70’

x 40’ wide system in use manufacturing thermoformed RV.

AVT and its subsidiary NescCo, are leading designers

and manufacturers of thin and heavy gauge thermoforming

and vacuum forming systems and accessories.

For additional information, contact AVT, 3870 M-61,

Gladwin, MI 48624, 989-246-0445, Fax: 989-246-

0465, E-mail: sales@adv-ven-tech.com, Web: www.advven-

tech.com.

SPE Booth #141

Sheet Fed Formers

& 5-Axis Trimmer

MAAC Machinery, a market leader in the manufacturing

of sheet fed thermoforming machines, will be

releasing several

new features to their Comet and MAAC

product lines at The SPE Thermoforming Conference.

More advanced control systems will allow control of all

machine parameters for the quickest set ups, along with

quick change vacuum, air and water packages, more quick

mold change systems and several advancements in specialty

clamping systems all allowing for faster set ups,

more machine time, as well as creating the ability for our

industry to gain more forming opportunities which may

not have been feasible previously.

new features to their Comet and MAAC

product lines at The SPE Thermoforming Conference.

More advanced control systems will allow control of all

machine parameters for the quickest set ups, along with

quick change vacuum, air and water packages, more quick

mold change systems and several advancements in specialty

clamping systems all allowing for faster set ups,

more machine time, as well as creating the ability for our

industry to gain more forming opportunities which may

not have been feasible previously.

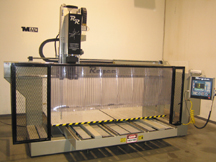

MAAC, with their joint partnership with Stopol, will also

be re-introducing their newest product line, the Royce

Router, a 5-axis CNC trimming

machine. The Royce

has been specifically

designed for the

secondary trimming

needs of the

sheet fed thermoforming

industry.

It offers fast feeds

and speeds, high

quality and reliable

components setting

the pace in reliability, repeatability and parts per hour.

Through this same partnership with used machinery

dealer Stopol, MAAC will now offer complete trade-in programs

available for both thermoforming machines and

CNC routers.

With additional partnerships and resources, MAAC will

also be offering complete single source turn-key packages,

from thermoforming machines and molds, to trimming

machines and fixtures, also including all automation, auxiliary

equipment and related services.

For additional information, contact Michael Alongi,

MAAC Machinery Corporation, 590 Tower Blvd., Carol

Stream, IL 60188, 800-588-MAAC/630-665-1700, Fax:

630-665-7799, E-mail: sales@maacmachinery.com,

Web: www.maacmachinery.com.

SPE Booth #326

Robotic Trimming

Solutions

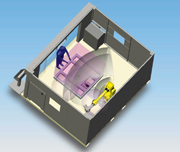

Robotic Production Technology (RPT) will show the latest

addition to its family of standard router trimming

systems, the RoboTrim™ RT-500, at the SPE Thermoforming

Conference. The RoboTrim RT-500 is a new pre-engi-

neered router trimming

and knife deflashing system

designed specifically

for the plastics industry.

The RT-500’s increased

part height capability

gives customers the flexibility

to process a variety

of part sizes and shapes.

The system’s speed and

reliability result in more

uptime and higher throughput to consistently deliver more

parts per hour than other trimming methods.

for the plastics industry.

The RT-500’s increased

part height capability

gives customers the flexibility

to process a variety

of part sizes and shapes.

The system’s speed and

reliability result in more

uptime and higher throughput to consistently deliver more

parts per hour than other trimming methods.

The RT-500’s riser-mounted robot and servo-controlled

rotating table allow it to easily process 60” x 60” x 36”

high parts typical of thermoformers. Longer parts of up to

80” x 36” with shorter heights can also be processed.

RPT will also show the RoboTrim RT-1000 router trimming

solution. The machine is

designed to use one

or two FANUC M-

16iB robots and an

aux-axis servo-controlled

10’ rotating

table.

RPT developed

application-specific

software

tools – RPT RouterWare – that make the

system easy to use.

RPT developed

application-specific

software

tools – RPT RouterWare – that make the

system easy to use.

Options include addition of a second robot, increased

part height and automatic tool change. The system can

also be used for deflashing by adding the patent-pending

RPT Compliant Knife. Manufacturers can also add the RPT

RouterVAC high volume vacuum system for part hold

down and chip removal and RPT TrimPro offline programming

software.

For additional information, contact Roberta Zald,

Robotic Production Technologies, 1255 Harmon Road,

Auburn Hills, MI 48326, 248-829-2800, Fax: 248-829-

2750, E-mail: solutions@rpt.net, Web: www.rpt.net.

SPE

Booth #440

New 3-Axis CNC

Router Series

Quintax Inc. is expanding its product offering with the

introduction of a line of 3-axis CNC routers engineered

primarily for flat sheet material users in the plastics,

wood and sign industries.

The Quintax Express Series routers are five machine

models with single-tables ranging from 2’x 2’ to 5’x 10’

with Z-axis heights to 5.1 inches.

Spindles available on

the Express Series range from 1.5 to 5 hp and operate up

to 24,000 rpm.

Spindles available on

the Express Series range from 1.5 to 5 hp and operate up

to 24,000 rpm.

Standard features

include; a

heavy-duty rack

and pinion axis

drive system,

high-torque AC

steppermotors,

PC-based controls

and nesting

software. All machines ship assembled and ready for

operation.

Quintax manufacturers a complete line of industrial 3-

and 5-axis CNC routers for accurate high-speed trimming,

cutting and shaping of plastics, composites, non-ferrous

metals and wood. Quintax moving table and gantry style

CNC routers are available in a broad range of sizes and

horsepowers.

For additional information, contact Eric Kenney,

Quintax, Inc., 4445 Allen Road, Stow, OH 44224, 330-

920-9200, Fax: 330-920-4200, E-mail: sales@quintax

.com, Web: www.quintax.com.

SPE Booth #426

Custom Extruded Sheet

PMC, one of the fastest growing custom plastic extruders

in the Midwest, will be sponsoring and exhibiting

at the SPE Thermoforming Conference.

“We are honored to be a part of the Thermoforming

Conference in Nashville,” said PMC Vice President of Sales

and Marketing Rich Zydonik. “The thermoforming industry

has been one of the major reasons for our tremendous

growth over the past twelve months and we are looking

forward to meeting with our industry friends and contacts

to see how we can continue to help them be successful.”

PMC has added three manufacturing representative

firms to its team in the past three months: Leathertone,

Inc. in the Northeast, Kerry Bone & Associates in the

Southeast, and Boles & Associates in the South and

Lower Midwest. The addition of these firms will allow PMC

to continue to expand its service area.

PMC is a division of Rowmark, Inc., the industry’s leading

manufacturer of signage and engraving materials.

For additional information, contact George Privateer,

PMC, 2040 Industrial Drive, Findlay, OH 45840, 877-

BUY-PMC6/419-425-8974, E-mail: gprivateer@rowmark.com, Web: www.buypmc.com.

SPE Booth #325

5-Axis CNC Router

Thermwood will exhibit the Model 90, an all new 5-axis

CNC router. It targets high speed trimming of threedimensional

parts. Cycle times are dramatically faster, on

some parts twice as fast with its advanced drive, lighter,

stiffer structure and Impact Resistant Head. The new

patented Impact Resistant Head is

lighter, stiffer and yet

reduces or eliminates

the

need to

realign

the head

after an

accidental

crash,

something that

is common during

programming and set-up.

The Model 90 has a larger envelope that allows full horizontal

table coverage side to side and front to back.

Mechanical structures were designed using finite element

analysis, a sophisticated CAD technology that scrutinizes

strength, stiffness, deformation and dynamics of the

machine structure. This is used to increase its strength,

stiffness and ultimately performance. All weldments are

stress relieved to further increase strength, stiffness and

provide long term stability and each machine is laser calibrated

to assure accuracy.

Mechanical structures were designed using finite element

analysis, a sophisticated CAD technology that scrutinizes

strength, stiffness, deformation and dynamics of the

machine structure. This is used to increase its strength,

stiffness and ultimately performance. All weldments are

stress relieved to further increase strength, stiffness and

provide long term stability and each machine is laser calibrated

to assure accuracy.

The Model 90 represents a new generation of trimming

machine, offering high-speed motions, a large envelope,

resistance to common set-up problems and alignments

capable of running CAD generated programs accurately.

For additional information, contact Cliff Crawford,

Thermwood Corporation, P.O. Box 436, Dale, IN 47523,

800-533-6901/812-937-4476, Fax: 812-937-2956, E-mail:

sales@thermwood.com, Web: www.thermwood.com.

SPE Booth #335, also see them at IWF Booth #8826

|