|

UHMW-PE Protective Piling Covers

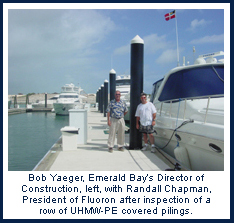

Bob Yaeger, Emerald Bay’s

Director of Construction,

was faced with a problem.

The coating on the steel pilings

was not standing up to the

mechanical and salt-water environment

of their floating piers.

In addition, the appearance was

unfit for a marina of their caliber.

The solution would be the

first of its kind. Allen

Klingensmith of Devcon

Construction & Materials Corp.,

builders of the marina, had to

solve the problem. They contacted

Fluoron, Inc. inquiring if

they could protect the pilings

with Ultra High Molecular

Weight Polyethylene (UHMW-PE). Its rich, attractive

appearance would be very desirable, while providing the

best wear protection and corrosion resistance available.

Bob Yaeger, Emerald Bay’s

Director of Construction,

was faced with a problem.

The coating on the steel pilings

was not standing up to the

mechanical and salt-water environment

of their floating piers.

In addition, the appearance was

unfit for a marina of their caliber.

The solution would be the

first of its kind. Allen

Klingensmith of Devcon

Construction & Materials Corp.,

builders of the marina, had to

solve the problem. They contacted

Fluoron, Inc. inquiring if

they could protect the pilings

with Ultra High Molecular

Weight Polyethylene (UHMW-PE). Its rich, attractive

appearance would be very desirable, while providing the

best wear protection and corrosion resistance available.

Fluoron’s U.S. patent #6,471,627B2 was the perfect

solution. Fluoron makes thin wall tubing in diameters

ranging from 6” to

100”. By taking a

UHMW-PE sheet

with 1/32”-1/8”

thickness and

seaming it in

lengths up to 39’

long, Fluoron was

able to make protective

piling covers.

Fluoron’s primary

business is

making heat

shrinkable tubing

of Teflon®, PTFE

and FEP for roll covers in the paper industry. They started

making UHMW-PE tubes because of the materials superior

toughness and

wear resistance.

These characteristics

of UHMW-PE

made it the ideal

product for the

marina pilings.

making UHMW-PE tubes because of the materials superior

toughness and

wear resistance.

These characteristics

of UHMW-PE

made it the ideal

product for the

marina pilings.

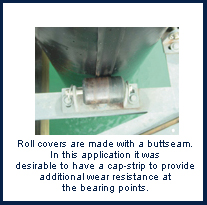

Fluoron has proprietary

equipment

for seaming tubes

from a 1/16”

UHMW-PE sheet.

Conventional butt-welding equipment is incapable of

seaming plastics of this thickness

and completely ineffective

in seaming UHMW-PE. Fluoron’s process makes the

tubing heat shrinkable.

It can then be shipped

for installation at a mill

site or marina.

and completely ineffective

in seaming UHMW-PE. Fluoron’s process makes the

tubing heat shrinkable.

It can then be shipped

for installation at a mill

site or marina.

Randall Chapman,

President of Fluoron,

stated, “This new product

is available in various

colors, such as red

and green for channel

markers.”

For more information, contact Michael

Geary, Fluoron, Inc.,

505 Blue Ball Road, Building #120, Elkton, MD 21921,

800-785-4491/410-392-0220, Fax: 410-392-4357,

E-mail: sales@fluoron.com, Web: www.fluoron.com.

|