|

Antimicrobial Acetals

The growing concern over bacterial

contamination in many settings

has led Ticona, the engineering polymers

business of Celanese

Corporation, to introduce Anti-

Crobe™ Antimicrobial Polymers, a

family of antimicrobial acetal copolymers

(POM) that includes two injection

molding grades and an extrusion

grade. The line is targeted at applications

calling for high-performance

polymers in environments where

heat, moisture and nutrients foster

bacterial and fungal growth.

has led Ticona, the engineering polymers

business of Celanese

Corporation, to introduce Anti-

Crobe™ Antimicrobial Polymers, a

family of antimicrobial acetal copolymers

(POM) that includes two injection

molding grades and an extrusion

grade. The line is targeted at applications

calling for high-performance

polymers in environments where

heat, moisture and nutrients foster

bacterial and fungal growth.

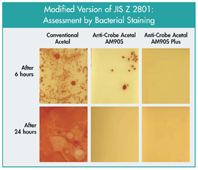

Evaluations of these grades, which are made with the

company’s Hostaform® and Celcon® POMs, found they

greatly inhibit microbial proliferation compared to conventional

acetal.

“The advanced, inorganic antimicrobial formulation in

these grades is present throughout the polymer matrix,

not just on the surface, and does not migrate significantly,”

says Davida Barrett, Technical Marketing. “This means that

Anti-Crobe resins won’t abrade or

scratch off, so they preserve product

performance and service life by deterring

bacteria and fungal attack that

can cause odors, contamination,

stains, biofilms and mechanical property

loss.”

Anti-Crobe Antimicrobial Polymers

comply with FDA regulations for direct

food contact, meet the NSF 61 Potable

Water standard and satisfy applicable

EPA regulations. They are naturally

white and can be tinted as needed.

Anti-Crobe POMs are suitable for

many end uses, especially in hard-to-clean wet areas and

where polyolefins cannot meet performance specifications.

Their possible applications include food processing,

storage and handling systems, industrial gears in wet environments,

and elements in water treatment plants.

For more information, contact Robert Shaw, Ticona,

8040 Dixie Highway Florence, KY 41042, 800-833-4882, E-mail: prodinfo@ticona.com, Web: www.ticona.com.

|