|

THERMOFORMING: Thermoforming Spotlight

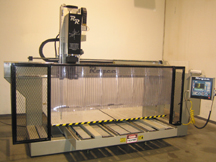

Enclosed Overhead

Gantry Router

DMS CNC Routers

introduced their latest

model – the

DMS Model

505-12-5-48S

enclosed 5-

axis overhead

gantry. This

router comes

with a 12’ x 5’

table which can

be used in a single or twin table

configuration with 4’ of Z axis stroke.

Spindles are available in either double-ended

or tool change style with a wide range of hp. Fagor

controls with TCP/IP network connection, flash memory card

and remote telediagnostics are standard.

model – the

DMS Model

505-12-5-48S

enclosed 5-

axis overhead

gantry. This

router comes

with a 12’ x 5’

table which can

be used in a single or twin table

configuration with 4’ of Z axis stroke.

Spindles are available in either double-ended

or tool change style with a wide range of hp. Fagor

controls with TCP/IP network connection, flash memory card

and remote telediagnostics are standard.

The entire line of DMS enclosed 5-axis machines range

in sizes from 3’ x 3’ to 12’ x 12’ single and twin shuttle

table configurations. All axes are driven by state–of-theart

brushless AC servo motors and digital drives. Twelve

position traveling servo driven tool changers feature 10-

second tool changes.

For additional information, contact Denny Brazelton,

Premier Tech Products, Inc. at 330-923-3125 or Jeff

Stein, Creative Machine Technology, Inc. at 330-923-

2154. Or visit their website at www.5axiscncrouter.com.

Thin Gauge Plastic Sheet

Ensinger announced that they are now stocking

TECAPEEK™ 2’ x 4’ thin gauge sheet available in .040”,

.080”, .093”, .118”, .187” thicknesses as well as sizes in

between by request. TECAPEEK™ has excellent properties

for use in general industry, electronics, semi conductor,

marine, automotive, and aerospace.

Tecapeek™ offers exceptional heat, chemical, dielectric,

wear, radiation, and mechanical properties. It also has

superior wear resistance and dimensional stability.

Ensinger, headquartered in Washington, Pa., is a world

leader in engineering stock shape plastics.

For additional information, contact customer service,

Ensinger Industries, 365 Meadowlands Blvd., Washington,

PA 15301, 800-243-3221/724-746-6050, Fax: 724-746-

9209, E-mail: sales@ensinger-ind.com.

Sheet Sample Kit

Kleerdex Co. LLC, offers its updated

KYDEX® sheet sample kit produced

specifically for thermoforming processing.

Each kit includes general

information about the more than

30 grades of KYDEX thermoplastic

sheet available to

thermoformers and fabricators.

specifically for thermoforming processing.

Each kit includes general

information about the more than

30 grades of KYDEX thermoplastic

sheet available to

thermoformers and fabricators.

The kit includes a

Product Selection Guide,

which details the physical

properties of each product, as

well as suggested applications, product highlights, production

capability and environmental and safety considerations.

Sample chip chains with product thickness specifications

in a variety of textures, colors and product grades,

including wood grain, metallic and fluorescent, also are

included. Specific application kits are also available upon

request.

KYDEX sheet is a premier thermoforming material offering

numerous processing advantages such as extreme

formability, hot tear strength and the ability to maintain

uniform wall thickness.

For additional information, contact Customer Service,

Kleerdex Company, 6685 Low Street, Bloomsburg, PA

17815, 800-325-3133/570-389-5810, Fax: 570-387-

7786, E-mail: info@kleerdex.com, Web: www.kydex.com.

Next Generation Robotic

Router Trimming System

KMT Robotic

Solutions, the

world’s leading

designer and

manufacturer of

robotic waterjet,

router, laser

and knife trimming

systems,

introduced the

RoboTrim™ RT-

1002 – the latest in KMT’s line of cost-effective, turnkey

robotic router trimming systems that help thermoformers,

plastics molders and composite manufacturers increase

throughput, uptime and employee safety.

world’s leading

designer and

manufacturer of

robotic waterjet,

router, laser

and knife trimming

systems,

introduced the

RoboTrim™ RT-

1002 – the latest in KMT’s line of cost-effective, turnkey

robotic router trimming systems that help thermoformers,

plastics molders and composite manufacturers increase

throughput, uptime and employee safety.

The system not only trims parts more than 50 percent

faster than traditional five axis CNC’s but also offers substantial

trimming flexibility, saving manufacturers valuable

time and money. The ergonomic design also improves

employee safety by distancing operators from the potentially

harmful trimming environment.

The standard model features a robot mounted inside a

steel enclosure. The system’s two-sided rotating table has

a 1,000 pound part and fixture capacity and can rotate 3

foot by 5 foot (and sometimes longer and narrower) parts

into and out of the cell in less than three seconds. This

allows finished parts to be safely unloaded by the operator

while unfinished parts are being trimmed inside the

cell. Manufacturers can also customize the system by

adding a variety of optional features including a second

robot, KMT’s patented compliant knife or the automatic

tool change option and others.

For additional information, contact Suzanne Carter,

KMT Robotic Solutions, Inc., 1255 Harmon Road, Auburn

Hills, MI 48326, 248-829-2800, Fax: 248-829-2750,

E-mail: robotic.na@kmtgroup.com, Web: www.kmtgroup.com.

Clamping System

Lenzkes Clamping Tools Inc. offers clamping systems for

all kinds of manufacturing machines. At the Thermoforming

Show in Cincinnati, Lenzkes introduced their system

to the thermoforming.

With clamping

forces up

to 18,000 ft

lbs per clamp,

due to their

forged special

alloy steel,

the system is

capable of

holding any

mold, large or

small, in

place. This patented technology has drawn interest from

several thermoforming equipment makers who are considering

making it standard equipment for their machines.

all kinds of manufacturing machines. At the Thermoforming

Show in Cincinnati, Lenzkes introduced their system

to the thermoforming.

With clamping

forces up

to 18,000 ft

lbs per clamp,

due to their

forged special

alloy steel,

the system is

capable of

holding any

mold, large or

small, in

place. This patented technology has drawn interest from

several thermoforming equipment makers who are considering

making it standard equipment for their machines.

Their Quick-Release Clamping system is stepless and

adjustable both horizontally and vertically by simply sliding

the clamping arm up to the mold and tightening the

ball pressure screw located in the back of the arm.

With increasing focus on lean manufacturing, mold

changes are one area in the thermoforming industry that

needs improvement. The Lenzkes system provides easy

adjustment for a wide variety of mold sizes and will reduce

down-time on your machines.

For additional information, contact Mike Brocher,

Lenzkes Clamping Tools, Inc., 825 Radford Road,

Christiansburg, VA 24073, 540-381-1533, Fax: 540-

381-4484, E-mail: m.brocher@lenzkes.com, Web:

www.lenzkesusa.com.

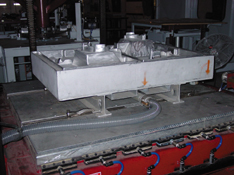

Twin Sheet Pressure

Formers

MAAC Machinery, an industry leader in thermoforming

machinery and systems, is now producing a new, upgraded

line of Twin Sheet Pressure Formers that have options

available to perfect even the most complicated parts. With higher pressures,

now exceeding

100

psi, faster platen

speeds, up

to 20” per second

and faster

rotation times,

as low as 3 seconds,

these

machines are

producing highly

detailed, unique twin sheet parts at record speeds.

line of Twin Sheet Pressure Formers that have options

available to perfect even the most complicated parts. With higher pressures,

now exceeding

100

psi, faster platen

speeds, up

to 20” per second

and faster

rotation times,

as low as 3 seconds,

these

machines are

producing highly

detailed, unique twin sheet parts at record speeds.

MAAC’s brand new, advanced twin sheet sequencing capabilities,

tool rotating or shifting abilities, articulating twin

sheet clamp frames and custom twin sheet plug assisting

methods guarantee that even the most complex parts can

be more efficiently twin sheeted or pressure formed.

With new features like automatic lance adjustment, several

quick mold change systems and adjustable clamp

frames, these upgraded machines will allow any thermoformer

to decrease changeover time and increase production

rates. New automatic loading and unloading options

allow for full automation.

For additional information, contact Michael Alongi,

MAAC Machinery Corp., 590 Tower Blvd., Carol Stream,

IL 60188, 630-665-1700, Fax: 630-665-7799, E-mail:

sales@maacmachinery.com, Web: www.maacmachinery.com.

Thermoforming Line

Modern Machinery’s Single Station thermoforming

machine is ideal for manufacturing large or small parts at a

modest cost. They offer flexibility

and versatility. Comparably,

their Double Ender’s offer

increased productivity

by allowing

multiple

sheets

to process

simultaneously.

They offer

Three and

Four Station Rotary

with standard features like electric drive platens and servo

drive index, as well as a multitude of customizable options.

and versatility. Comparably,

their Double Ender’s offer

increased productivity

by allowing

multiple

sheets

to process

simultaneously.

They offer

Three and

Four Station Rotary

with standard features like electric drive platens and servo

drive index, as well as a multitude of customizable options.

With Modern Machinery’s Trim Press, finished parts are

automatically nested for packaging or further processing.

They are available in different mold sizes and tonnage ratings.

All Modern Clamp Frames are constructed of heavyduty

extruded aluminum and can be

retrofitted into existing equipment. The 4-Way Adjustable

Style is adjustable in both directions, eliminating the need

for tools and greatly reducing machine down time. Top and

bottom load systems are available in 4-Way Adjustable

and standard styles.

Modern Machinery provides several Upgrade Kits for

your existing equipment.

For additional information, contact Brian Winton,

Modern Machinery of Beaverton, Inc., 3031 Guernsey

Road, P.O. Box 423, Beaverton, MI 48612, 888-649-

9839, Fax: 989-435-3940, E-mail: info@modernmachineinc

.com, Web: www.modernmachineinc.com.

Cutting Tools

Onsrud Cutter LP, a leading supplier of CNC

router tooling, announced a new line of solid carbide

taper tools from 1/8” to 1/4” in cutting

diameter with cutting angles per side ranging

from 1 to 7 degrees. The ball nose tip is ideal for

3-D decorative profiles, and the taper profile

allows production of draft angles in molds. The

spiral design produces an excellent finish in

wood, plastic and aluminum. Custom designs can

be made upon request.

router tooling, announced a new line of solid carbide

taper tools from 1/8” to 1/4” in cutting

diameter with cutting angles per side ranging

from 1 to 7 degrees. The ball nose tip is ideal for

3-D decorative profiles, and the taper profile

allows production of draft angles in molds. The

spiral design produces an excellent finish in

wood, plastic and aluminum. Custom designs can

be made upon request.

For additional information, contact Diane

Sullivan, Onsrud Cutter LP, 800 Liberty Drive,

Libertyville, IL 60048, 847-362-1560, Fax:

847-362-5028, E-mail: dsullivan@onsrud.com,

Web: www.onsrud.com.

New & Used Equipment

plastiMACH Corp. is a stocking dealer of used plastic

thermoforming and packaging equipment since 1975.

Most of their late-model inventory can be inspected in

New York or Chicago warehouses. They also represent all

major manufacturers

of new thermoforming

machinery,

including single station,

rotary double

end and inline

equipment. They

can help you select

the right machine

for your application

and budget, with over 75 years of experience in the thermoforming

and routing industry.

Most of their late-model inventory can be inspected in

New York or Chicago warehouses. They also represent all

major manufacturers

of new thermoforming

machinery,

including single station,

rotary double

end and inline

equipment. They

can help you select

the right machine

for your application

and budget, with over 75 years of experience in the thermoforming

and routing industry.

plastiMACH Corp.

also introduces their

C N C R outer

Store.com division.

The CNC Router

Store is dedicated to

providing a selection

of new and used

CNC routers to the plastics industry. They carry used CNC

routers from Thermwood, Motionmaster, C.R. Onsrud,

Komo, Quintax, Multicam, Anderson, Omnitech and others.

They also carry the new line of CNT Motion Systems

routers with complete 3-axis CNC Router packages.

plastiMACH Corp.

also introduces their

C N C R outer

Store.com division.

The CNC Router

Store is dedicated to

providing a selection

of new and used

CNC routers to the plastics industry. They carry used CNC

routers from Thermwood, Motionmaster, C.R. Onsrud,

Komo, Quintax, Multicam, Anderson, Omnitech and others.

They also carry the new line of CNT Motion Systems

routers with complete 3-axis CNC Router packages.

For additional information, contact Jerry Hammerman,

plastiMACH Corp., 704 Executive Blvd., Valley Cotage, NY

10989, 845-267-2985, Fax: 845-267-2825, E-mail: jerryh@

plastimach.com, Web: www.plastimach.com.

Thermoformable

Materials

Premier Material Concepts (PMC) introduced Exultra™

the first cost-effective, “green,” recycleable product for

interior and exterior applications and specifically engineered

for the thermoforming industry.

the first cost-effective, “green,” recycleable product for

interior and exterior applications and specifically engineered

for the thermoforming industry.

Exultra is an innovative product that offers an alternative

to vinyl-wrapped materials, without the additional labor,

cost and waste. It eliminates many secondary

processes and allows customers to reclaim the fall-off

associated with

the thermoforming

process.

There are currently

two products

in the Exultra

line. Exultra

3000, a patentpending

3-ply

formable product

that consists of a

weatherable elastomeric cap layer laminated to an

expanded elastomeric foam middle layer then laminated

to a high impact thermoplastic olefin core layer.

Exultra 2000 is a 2-ply formable product that consists

of a weatherable elastomeric cap layer laminated to a

high impact thermoplastic olefin layer. Ideal applications

include instrument panels, dashboards, decorative trim,

consoles, door panels, flooring, interior fitness equipment,

seating and organizational devices. Both Exultra products

are outdoor weatherable and contain UV stabilizers

throughout the product. Exultra products also have

improved impact strength over ABS and are moisture,

scratch and mar resistant.

For additional information, contact George Privateer,

Premier Material Concepts, 2040 Industrial Drive,

Findlay, OH 45840, 877-BUYPMC6/419-425-8974, Email:

sales@buypmc.com, Web: www.buypmc.com.

3- & 5-axis Router Line

Quintax designs and manufactures a complete line of

quick, accurate and robust industrial 3- and 5-axis CNC

routers for accurate high-speed robotic trimming, cutting

and shaping of plastics, composites, carbon-fiber, non-ferrous

metals and wood. Choose from Quintax single or

twin table machines in various table sizes

with mechanical hold-down or integral

table vacuum system. All

Quintax CNC routers

can be equipped

with a choice of

CAD/CAM packages.

Quintax offers

very rigid construction,

many standard

design features, training

and technical support.

Custom engineered CNC

routers are also available.

quick, accurate and robust industrial 3- and 5-axis CNC

routers for accurate high-speed robotic trimming, cutting

and shaping of plastics, composites, carbon-fiber, non-ferrous

metals and wood. Choose from Quintax single or

twin table machines in various table sizes

with mechanical hold-down or integral

table vacuum system. All

Quintax CNC routers

can be equipped

with a choice of

CAD/CAM packages.

Quintax offers

very rigid construction,

many standard

design features, training

and technical support.

Custom engineered CNC

routers are also available.

For additional information, contact Eric Kenney,

Quintax, Inc., 4445 Allen Road, Stow, OH 44224, 330-

920-9200, Fax: 330-920-4200, E-mail: sales@quintax.com, Web: www.quintax.com.

5-Axis Line

Royce Routers are a new line of 5-Axis CNC routers

designed specifically for the cut sheet thermoforming

industry, manufactured by MAAC Machinery. The R55T5A

is a twin-table machine featuring two 60”x 60” tables. The

tables can be operated independently or as a single 120”

x 60” table. The unique one-piece construction fits within

a standard 10’ x 12’ doorway and does not require an

installation.

designed specifically for the cut sheet thermoforming

industry, manufactured by MAAC Machinery. The R55T5A

is a twin-table machine featuring two 60”x 60” tables. The

tables can be operated independently or as a single 120”

x 60” table. The unique one-piece construction fits within

a standard 10’ x 12’ doorway and does not require an

installation.

Mass production of a single model will deliver the maximum

value at the most cost-effective price. The new

Royce Router combines the latest technology and

increased speeds to improve cycle times up to 400%.

With faster feeds and speeds, higher quality, enhanced

accuracy and more reliable components, these machines

are raising the industry’s standards.

Royce Router

offers full service

and parts availability

from

stock.

For additional

information, contact

Michael

Alongi, Royce

Routers LLC,

590 Tower Blvd.,

Carol Stream, IL

60188, 630-665-1700, Fax: 630-665-7799, E-mail:

sales@maacmachinery.com, Web: www.maacmachinery.com.

Conductive Sheet

Products

RTP Company’s Sheet and Film Division has recently

developed new conductive sheet products including the

addition of polyethylene, polypropylene (PP) and polyethylene

terephtalate glycol (PETG) sheet. The most significant

improvements are in the PETG sheet, which provides

unique benefits, including a higher purity than is typical

for sheet products and low-outgassing.

addition of polyethylene, polypropylene (PP) and polyethylene

terephtalate glycol (PETG) sheet. The most significant

improvements are in the PETG sheet, which provides

unique benefits, including a higher purity than is typical

for sheet products and low-outgassing.

The conductive sheet offers surface resistivity levels

ranging from <104 through 1011 ohm/sq and presents

further options, such as flame retardance, wear resistance

and color. Additionally, custom sheet and film from RTP

Company are available in both thin gauge and thick

gauge.

Conductive sheet is ideal for a wide range of applications,

including

anti-static

labels, bags

and other ESD packaging products.

Conductive

sheet also provides

resistive

heating, which

offers a defense with the material being used as a resistor.

Other products that utilize conductive sheet are electronic

device in-process trays and shipping media.

For additional information, contact Christin Ruge, RTP

Company, 580 East Front Street, Winona, MN 55987,

507-454-6900, Fax: 507-454-2089, E-mail: cruge@

rtpcompany.com, Web: www.rtpcompany.com.

Next Generation CNC

Router Control

Technology

Thermwood builds a complete line of three and five axis

CNC routers from high speed systems for routing, trimming

and pattern making to large envelope systems for

aerospace and defense. All Thermwood CNC routers now

include advanced CNC control technology called “Next

Generation Control.” Next Generation Controls provide

easier programming and program execution: as with

three-axis machines, accepting

the part design directly without

having to convert it to CNC

code. A new advanced

motion control

engine provides

better

machine motion

and accuracy.

CNC routers from high speed systems for routing, trimming

and pattern making to large envelope systems for

aerospace and defense. All Thermwood CNC routers now

include advanced CNC control technology called “Next

Generation Control.” Next Generation Controls provide

easier programming and program execution: as with

three-axis machines, accepting

the part design directly without

having to convert it to CNC

code. A new advanced

motion control

engine provides

better

machine motion

and accuracy.

The new

generation control

provides

advanced communications including tracking and notification

for routine maintenance along with tool use and life.

It provides three-dimensional views identifying machine

errors and plays video instructions, showing the operator

how to perform maintenance and repairs.

A fully searchable operator’s manual is integrated within

the control, along with the ability to view, move, rotate

and explode CAD drawings of every major assembly on

the machine. Thermwood’s Gen2 new generation control

can access Thermwood technical help through the

audio/video/date link connecting the operator directly to

an experienced technician who can then assist with technical

help from programming assistance to making adjustments

within the control.

For additional information, contact Cliff Crawford,

Thermwood Corporation, P.O. Box 436, Dale, IN 47523,

800-533-6901/812-937-4476, Fax: 812-937-2956,

E-mail: sales@thermwood.com, Web: www.thermwood.com.

|