|

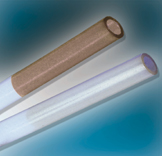

New Fluoropolymer Etched Tubing Increases Shelf Life

Parker-TexLoc now offers

etched Fluoropolymer tubing

with 50% more shelf life than

conventional etched products

and a 20% higher dyne rating.

The added strength that lengthens

the shelf life also strengthens

the intensity of the etch,

thus creating a stronger bond

when fused to other objects.

Typically, the improved Fluoropolymer

Etched Tubing, made

to Parker TexLoc standards,

has a 10% to 30% deeper etch

than products etched with a similar

medium and in a similar

fashion. Etch depth is measured in angstroms.

Typically, the improved Fluoropolymer

Etched Tubing, made

to Parker TexLoc standards,

has a 10% to 30% deeper etch

than products etched with a similar

medium and in a similar

fashion. Etch depth is measured in angstroms.

Because the lubricity of the Fluoropolymer tubing surface

hampers its bondability/wettability, etching is

required to alter the molecular structure of the surface.

The chemical reaction between the etch medium and the

tubing strips the fluorine molecules exposing the carbon

molecules. Once the surface lubricity has been altered,

the tubing can be bonded to almost any surface.

Although etching alters the color of the tubing, with colors

ranging from light bronze to a dark burnish brown,

the color of the etch does not

necessarily determine the

strength of the etch.

When etched tubing is exposed

to UV light or elevated

temperatures, the etch quality

deteriorates exponentially. With

Parker TexLoc etched products,

the deterioration factor is retarded,

thus creating the longer shelf

life and the measurements showing

a higher dyne and lower contact

angle. A lower contact angle

gives a higher dyne which is

more desirable because it increases

the tube's ability to

bond with other objects.

Parker-TexLoc provides etching services for their products

on the I.D., O.D. or both and the process is available

on most product lines. Sizes range from .060” up to 4”

I.D. Samples are available upon request.

For more information, contact Janine Kruit, Parker/

TexLoc, Parker Hannifin Corp., Parflex Division, 4700

Lone Star Blvd., Ft. Worth, Texas 76106, 800-423-6551,

Fax: 800-438-9562, E-mail: texloc@texloc.com, Web:

www.texloc.com.

|