|

Performance for Tough Environments

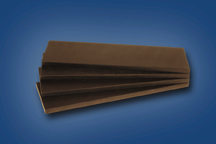

Norplex-Micarta announced the NP193 series of materials

for applications requiring excellent dimensional stability,

high wear resistance and superior mechanical

strength.

The

NP193

series

includes

four

grades,

NP193E,

NP193M,

NP193P and NP193PM: all are available in sheet form

measuring 4’ x 5’ and up to 2” thick. Each grade features a proprietary blend of aramid fabric substrates impregnated

with various resins.

NP193E uses a high temperature epoxy resin for high

wear resistance. NP193M uses a melamine resin, which

makes it impervious to corrosives, such as anhydrous

ammonia. It’s the optimal replacement for asbestos in

refrigeration compressors.

NP193P combines a high temperature

phenolic resin system with woven aramid

fiber/glass fabric for excellent mechanical strength.

NP193PM combines high-temperature phenolic resin with

aramid and “soft glass” fibers and a non-conducting solid

lubricant. It has excellent mechanical strength at elevated

temperatures and in adverse chemical environments, making

it an ideal material for wear plates in conveyor systems,

valve plates and compressor and pump vanes.

For more information, contact Alan Johnson, NORPLEX-

MICARTA, 665 Lybrand Street, Postville, IA 52162,

563-864-4275, Fax: 563-864-4231, E-mail: ajohnson@norplex-micarta.com, Web: www.norplex-micarta.com.

|