|

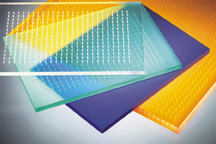

Sustainable Extrusion & Fabrication Techniques

As retailers seek ways to reduce the energy used and

waste produced across the supply chain, Eastman highlights

techniques for sustainable fabrication

of point-of-purchase displays

and in-store fixtures manufactured

with Eastman Spectar™ copolyester.

As retailers seek ways to reduce the energy used and

waste produced across the supply chain, Eastman highlights

techniques for sustainable fabrication

of point-of-purchase displays

and in-store fixtures manufactured

with Eastman Spectar™ copolyester.

During the extrusion process,

Eastman uses 3.5 times less energy

than acrylic (PMMA). Eastman Spectar

copolyester is manufactured without

bisphenol-A (BPA), halogen, lead and

mercury. Combining these inherent

attributes with sustainable extrusion

and fabrication processes further decreases the environmental

footprint of displays manufactured using Spectar.

Eastman offers several advantages to enhance the

eco-profile of point-of-purchase displays and in-store

fixtures manufactured with Spectar; downgauging -

translates into material savings by enabling it to be

downgauged up to 20 percent compared to acrylic without

sacrificing durability; thermoforming

- design flexibility allows

retailers to create intricate shapes

for fixtures and displays, especially

when the material is thermoformed.

This process contributes to an energy

savings of up to 20 percent; regrinding

- reintroducing re-ground

Spectar trim scrap into a virgin

stream results in material savings

without sacrificing the material’s

inherent physical and visual properties.

For more information, contact Lucy Stewart, Eastman

Chemical Company, P.O. Box 431, Kingsport, TN 37662,

423-229-4229, E-mail: lstewart@eastman.com, Web:

www.eastman.com/spectar.

|