|

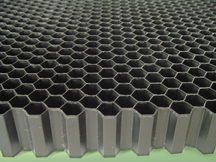

High Performance Honeycomb

PlastiCell of France announced it has developed an innovative

process for the production of lightweight thermoplastic

honeycomb structures using Victrex APTIV™ film.

The unique design of PlastiCell’s honeycomb provides an

ideal solution for aerospace and other industries seeking

to reduce weight while maintaining high levels of strength

and stiffness. APTIV thermoplastic honeycomb can be

thermoformed into shape in combination with fibre reinforced

VICTREX® PEEK™

polymer composite skins

to create unique structural

parts without the use

of adhesives. Consisting

only of PEEK polymer,

any scrap and end-of-life

parts can be fully recycled,

providing further

advantages over traditional phenolic/aramid fiber and aluminium

based honeycombs.

The thermoplastic film used for the honeycomb and for

the surface skins must fulfill the aircraft industry standards

for flame performance, smoke and toxicity, as well

as offering mechanical performance and low weight.

There is no size constraint, part size limitation is dictated

by the hydraulic press platen size. Flat and curved

parts can be made using this process and the unique flexibility

of the thermoplastic honeycomb even allows it to be

formed into cylindrical shapes.

For more information, contact Victrex USA, Inc.,

300 Conshohocken State Road, Suite 120, West Conshohocken, PA 19428, 800-VICTREX, Fax: 484-342-6002, Web: www.victrex.com.

|