|

Nylon & Acetal Shapes

Acetal Pipe and Tubing

DelStar Technologies, Inc. announced that they now manufacture

acetal pipe and tubing. They specialize in custom

work, and can manufacture custom acetal tubing and pipe

from 1/8” to 4” OD. DelStar is willing to stock proprietary

configurations for their customers. Custom products are

available with minimum order quantities.

DelStar Technologies, Inc., headquartered in

Middletown, Delaware, has manufacturing operations at

that location, as well as in Austin, Texas, Richland,

Pennsylvania, El Cajon, California and Suzhou, China.

DelStar Technologies also has international sales offices in

Bristol, England and Shanghai, China.

For additional information, contact Marjorie Wilcox,

DelStar Technologies, Inc., 220 East Saint Elmo Road,

Austin, TX 78745, 800-521-6713/512-447-7000, Fax:

512-447-7444, E-mail: mwilcox@delstarinc.com, Web:

www.delstarinc.com.

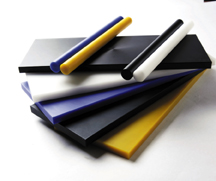

Acetals and Nylons for

Machining

Ensinger offers a

wide range of engineering

plastics

that are ideal for

machining a variety

of parts. Produced

in ISO 9001:2000

certified facilities

from premium

grade resins,

Ensinger materials show consistently low internal stress

that leads to dimensional stability and the ability to hold

tighter tolerances. Based on the application, designers

can choose from several popular brand name products,

including DELRIN®, TECAFORM™, TECAMID™ and

TECAST™.

DELRIN® and TECAFORM are acetal products that are

used extensively in bushings, bearings, pulleys and other

wear products. TECAFORM, an acetal copolymer, can be

found in general industrial bushings, rollers and pulleys.

Ensinger’s DELRIN shapes are made from homopolymer

resin manufactured by DuPont. They offer superior tensile

properties, fatigue endurance and creep resistance. They

are ideal for use in surface wear applications on conveyors

such as bushings, fittings and impellers. They also have

excellent chemical resistance to hydrocarbons, solvents

and natural chemicals. Both products exhibit low moisture

absorption.

TECAMID and TECAST are nylon products. TECAMID,

used in bushings, bearings, pulleys and other wear parts,

is extruded nylon that is chemical resistant to hydrocarbons,

ketones and esters. TECAST, a cast nylon, provides

an excellent combination of bearing properties, toughness,

strength and light weight. Stock shapes of TECAST

are available in almost limitless size range and can be cast

to custom specifications.

For additional information, contact Bruce Dickinson,

Ensinger, Inc., 365 Meadowlands Blvd., Washington, PA

15301, 800-243-3221/856-227-0500, Fax: 724-746-9209,

E-mail: sales@ensinger-ind.com, Web: www.ensingeronline.

com.

Extruded Stock Shapes

Hi-Tech Profiles, Inc.,

a leading manufacturer

of extruded stock

shapes, has entered

into its 22nd year of

service to the plastics

distribution industry.

Established in 1988,

the company has

grown steadily from

its initial roots, offering

only nylon and

acetal stock shapes,

to expanded product

lines with a broad

array of thermoplastic materials. Hi-Tech Profiles, an

ISO9001:2008 registered company, serves the industry

from its facility in Ashaway, Rhode Island along with its

two sister companies, HTP-Meds LLC, and Hi-Tech Molds.

The three companies combined offer concept to part service

with extremely fast turn around time.

Hi-Tech Profiles, specializes in the extrusion of all engineered

thermoplastic materials in sizes ranging from

0.050" to 2.5" OD. The company offers an extensive line

of tubing, hollow rod, and bushing stock in nylon and

acetal that is in stock and available for immediate shipment.

Custom sizes are quoted upon request with over

twenty different materials to choose from including;

ECTFE, Polycarbonate, PVDF and Polysulfone. Custom cutting

and printing are available upon request. Co-extruded

tubing with two and three layer construction, in sizes

ranging up to 1" OD, is also available.

For additional information, contact Brian McGregor, Hi-

Tech Profiles, Inc., 15 Gray Lane, Ashaway, RI 02804,

800-342-5495, Fax: 401-377-2423, E-mail: info@

hitechprofiles.com, Web: www.hitechprofiles.com.

High Impact Cast Nylon

Nylatech has developed a highly plasticized type 6 nylon.

It is called Nylatech IRG. This material retains the basic

physical properties of nylon 6 but has increased impact resistance. Since traditional

cast nylon 6

materials are semicrystalline,

they are

susceptible to cracking

and breaking

when subjected to

high impact loads

especially when the

part is nicked or

notched. Nylatech

IRG addresses this

issue. Due to the impact resistance of Nylatech IRG, it outperforms

these traditional grades in heavy impact applications

such as pile driving cushions. The material can also

be used in vibration dampening applications, mechanical

stops or other high impact situations. This material can be

produced in rods or discs up to 68" diameter, sheets in up

to 7" thick and tubes in up to 48" diameter.

For additional information, contact Calvin Petersen,

Nylatech, Inc., P.O. Box 455, Everson, WA 98247, 800-

506-9566/360-966-2838, Fax: 360-966-2838, E-mail:

nylatech@nylatech.com, Web: www.nylatech.com.

Stock Shapes

for the 21st

Century

Quantum Polymers manufactures

and sells engineering plastic and

high performance plastic stock

shape products. Engineering plastic

material offerings include acetal and

nylon. These materials are available

in unfilled, electrostatic dissipative

and carbon/glass/teflon fiber-reinforced

grades. Quantum specializes

in offering stock shape high performance

materials in short delivery

times, custom sizes and low minimums.

Quantum also develops custom

stock shape products for the most

demanding applications - those that

require physical, mechanical and

electrical properties beyond the

reach of standard off-the-shelf plastics

products.

Their state-of-the-art facility is

equipped with the latest manufacturing

and logistics technology to

produce cost-effective, high quality

products with unparalleled flexibility

in delivery

time.

Quantum's

dedicated

team of

experts has

a proven

track record

in the stockshape

industry.

For the

past 25

years, the

team has successfully deployed plastic materials in the

aerospace, bio-medical, energy, food processing, healthcare,

semiconductor and transportation industries.

At Quantum, their practice of "continuous innovation"

enables them to develop process technology and introduce

new materials to provide cost-effective plastic solutions

for demanding applications.

For additional information, contact Ellen Witherspoon,

Quantam Polymers, 211 Executive Drive, Suite 1, Newark,

DE 19702, 877-737-7012/302-737-7012, Fax: 302-

737-7035, E-mail: info@quantum-polymers.com, Web:

www.quantum-polymers.com.

|