|

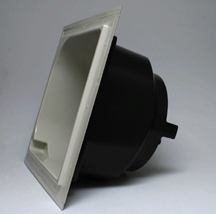

Thermoforming Spotlight

Enclosed Machining Center

This DMS Enclosed Overhead Gantry Machining Center

includes a generous 12’ x 5’ table with removable partition,

that when

configured in a

short bridge

format (shown)

creates a high production

Dual-Cell Trim

Center as well as

a scalable Mold & Pattern machining center.

When configured as a Long-Bridge Model (DMS 5O5-

12-5-36L) this machining center provides full unobstructed

front-load access to the entire 12’ x 5’ workspace using

a forklift or crane. The smart design of the machine can

accommodate from 36” to 60” of Z-Axis travels while still

shipping easily by truck or oceanic container from their

factory to your manufacturing floor.

Whether you’re machining honeycomb, composites

materials, aluminum, wood patterns, or plastics; this DMS

Machining Center can be customized and configured to

meet a wide range of manufacturing processes.

Features and options include: Fagor controls drives and

motors; continuous C-Axis; heavy

duty heads with liquid cooled spindles;

multi-position tool changers;

tool length setters; auto head alignment

verification; automatic doors;

remote operator panels and high speed

machining options. Additional

table sizes for long and short bridge

models are available in 60” x 60”,

96” x 60” and 120” x 60”.

For additional information, contact

Ed Hilligrass, Diversified Machine

Systems, Inc., 2310 Executive Circle,

Colorado Springs, CO 80906, 719-

226-5066, Fax: 719-226-9810,

E-mail: info@dmscncrouters.com,

Web: www.dmscncrouters.com.

Thermoformer

Line

MAAC Machinery, a market leader in

the manufacturing of sheet-fed thermoforming

machines, releasing several

new features and options to

their MAAC and Comet thermoforming

machine lines. New quartz oven

technology is providing for faster

cycle times and up to 50% energy

savings when compared

to prior technology.

More advanced

control systems now

allow control of all

machine parameters

for quick set ups and

precision repeatability.

New quick change

utility packages, quick mold change systems, and several

advancements in specialty clamping systems are further

allowing for faster set ups, more machine time, and the

ability to produce products more efficient and more cost

effective.

MAAC has also released new equipment offerings for the

growing composite and foam based material markets. In

particular, markets such as automotive, aerospace, medical

and anything where weight reduction, sound absorption,

and higher strength are becoming a demand. These

machines are geared toward higher pressure applications

utilizing matched mold processing and sometimes using

multiple layers of different materials. This new lineup of

machines is geared with faster platens and indexing, highly

sophisticated infrared heating ovens and typically automation

that will allow decorative coverings to be added.

For additional information, contact Michael P. Alongi,

MAAC Machinery Corporation, 590 Tower Boulevard,

Carol Stream, IL 60188, 800-588-MAAC/630-665-1700,

Fax: 630-665-7799, E-mail: sales@maacmachinery.com,

Web: www.maacmachinery.com.

Robotic Trimming System

KMT Robotic Solutions’ newest robotic routing system, the

RoboTrim® DRT-802, gives plastics and composites manufacturers

the ability to quickly and cost effectively process

parts up to 8’ x 8’ x 3’ in a more compact work area.

This new DRT (Dual Rotating Table) system utilizes a

rotating table mounted to each side of a two position

indexing wall. Each rotating table has a part holding fixture

mounted to

it, which allows

the system operator

to load or

unload parts on

one side of the

wall while the

robot is trimming

on the

other side. The

rotating tables

operate in coordination with the robot as it is trimming,

which allows large parts to be processed by a single robot

in a more compact work space.

Also available to further increase the throughput of this system

is a dual robot configuration. Adding the second robot

can, in some cases, halve the time required to trim the part.

“This new KMT system is making our plastics and composite

customers more competitive,” said KMT Robotic

Solutions General Industrial Sales Manager, Paul Schuch.

“The RoboTrim DRT-802 system is the big brother of the

RoboTrim DRT-502 system that KMT introduced in 2008.

Since then we found a market need for this new Dual

Rotating Table system capable of processing even larger

parts. Our customers are particularly pleased with the

safety aspects of this design which keeps the operator

separated from the rotating spindles.”

The DRT-802 in its standard configuration comes with a

single KMT AccuTrim® R-110 robot and two servo controller

rotating tables capable of coordinated motion with

the robot. The R-110 can utilize up to a 13 hp spindle with

automatic tool change and can trim parts up to 8’ x 8’ x

3’ high. In some cases, parts with larger lengths can also

be processed depending upon the other dimensions of the

part. The system can optionally be configured with a second

R-110 for higher throughput.

For additional information, contact Roberta Zald, KMT

Robotic Solutions, Inc., 1255 Harmon Road, Auburn Hills,

MI 48326, 248-829-2800, Fax: 248-829-2750, E-mail:

roberta.zald@kmtgroup.com, Web: www.kmtrobotic.com.

New Proprietary Sheet

New Proprietary Sheet

KYDEX, LLC, a worldwide leader in specialty thermoplastic

sheet manufacturing, announced the launch of KYDEX®

311 and KYDEX® 351 MB. Created in response to customer

requests for superior product at competitive prices,

these materials are symbolic of KYDEX’s industry-leading

culture of innovation. In keeping

with KYDEX’s green initiative, both

products contain reclaimed content

as a result of an environmentally

friendly, closed-loop manufacturing

process.

“Innovation is key to our success

at KYDEX,” explains Jim Medalie,

President of KYDEX, LLC. “We are

extremely proud of our ability to solve a simple problem –

high-quality thermoplastic materials at a competitive price

– with a revolutionary process.”

The success of KYDEX® 311 immediately led to the development

of KYDEX® 351 MB which features the added benefit

of Microban® antimicrobial protection. Microban®

inhibits the growth of bacteria that can cause stains, odors

and product deterioration. An integral part of the sheet, it

won’t wash or wear away, keeping the surface fresher

between cleanings for the entire life of the product.

The materials share many high-performance features:

cost competitive with fire-resistant ABS (FR-ABS) formulations;

impact resistant; excellent fabrication qualities with

good part definition; thicknesses from 1.5mm (0.060”) to

8.9mm (0.350”); less hygroscopic than FR-ABS (typically

do not require pre-drying); excellent resistance to a broad

range of corrosive chemicals and cleaning solutions; UL®

recognized Std 94 V-0/5V; available in a wide range of colors;

color-matched, co-extruded top layer with a black-colored

substrate for dark colors and an off-white-colored

substrate for light colors. Suggested applications include

exhibits and displays, medical products, store fixture components

and machine housings

For additional information, contact Ronn Cort, KYDEX,

6685 Low Street, Bloomsburg, PA 17815, 570-387-6997, E-mail: info@kydex.com, Web: www.kydex.com.

Thermoformable Sheet

Thermoformable Sheet

Premier Material Concepts (PMC) offers choice materials

for custom thermoforming applications, including Exultra™

soft touch TPO sheet for interior applications and rigid

high gloss TPO materials for exterior fairings and styling

components.

The advantages of TPO over other resins include

strength, durability, dimensional stability and recyclability.

PMC’s TPO sheet materials ensure improved cold temperature

impact performance and excellent chemical

resistance for dependable, long-lasting results.

The TPO products that

PMC manufactures are UV

stable, eliminating the need

for a protective weatherable

cap. With a CLTE (Coefficient

of Linear Thermal

Expansion) 50% that of

ABS, ductility to -30° C and

higher HDT (Deflection

Temperature), buckling between mating parts is reduced,

meaning TPO parts won’t crack, fade or degrade.

PMC TPO sheet materials have been designed for

improved thermoforming melt strength, reducing scrap

and increased processing throughput.

Unlike ABS/Vinyl, TPO products are recyclable, resulting

in lower material costs and environmental consciousness.

PMC offers TPO products in a variety of textures and

surface finishes to suit your custom needs. Decorative

ABS, HIPS and acrylics are also available.

For additional information, contact Kristin Larmore,

Premier Material Concepts, 2040 Industrial Drive, Findlay,

OH 45840, 877-BUYPMC6/419-429-7017, E-mail:

klarmore@rowmark.com, Web: www.buypmc.com.

Thermoformable Long

Glass Fiber Composite

Thermoformable Long

Glass Fiber Composite

Ensinger’s Penn Fibre Division now offers thermoformable

long glass fiber (LGF) polyolefin based composite sheet

under its Pennite™ glass reinforced sheet product line.

Thermoformable Pennite LGF Composite sheet has been

produced in glass

loadings ranging

from 20-35%. These

long glass fibers

improve the sag

characteristic of the

sheet and import

better physical properties

than what is

seen in short glass

fibers.

Penn Fibre General Manager, John Cowperthwait,

said,“We produce short glass fiber products in crystalline

resins such as nylon, PEEK, PPS, and amorphous polymers

such as Ultem™ PEI all the time. What we did not know was

whether we could get this into a sheet with the fiber intact,

and whether the sheet would be thermoformable using

conventional thermoforming equipment.” Testing by

Maryland Thermoform, Baltimore, MD, verified that the

LGF formed surprisingly well. Tammy Sagastume, Sales

Manager for Maryland Thermoform, said “We had real

doubts about its ability to form due to the obvious stiffness

and fiber length. But trials of .125 thick Pennite™

Composite sheet indicate we can certainly make parts from

it, and we already have a lot of interest in a variety of applications

that can take advantage of these properties.”

OEMs value the improved strength and stiffness, as well

as improved impact, creep, and fatigue resistance relative to

short glass fiber (SGF) compounds, particularly as metal

replacement for automotive products. Applications in the

automotive markets include: cross car beams; battery trays,

instrument panel substrates, fender supports, face shields,

seat backs, fan shrouds, load floors and bumper beams.

Due to high production volumes in automotive, thermoforming

has not been the process of choice. However, for

markets that have lower volume production needs, thermoforming

offers much lower fixed investment in terms of tooling

and equipment cost. These markets include: golf carts,

snowmobiles, mobile homes, RVs, motorcycles, construction,

truck and bus, aircraft, marine, or anywhere the composite’s

stiffness, strength and lower weight are important.

For additional information, contact Mark Kreisher,

Ensinger-Penn Fibre Division, 2434 Bristol Road,

Bensalem, PA 19020, 800-662-7366, Fax: 215-702-9552, E-mail: mark@pennfibre.com, Web: www.pennfibre.com.

New & Used Equipment

New & Used Equipment

PlastiMach Corporation is a stocking dealer of used thermoforming

equipment since

1975. Most of their latemodel

inventory can be

inspected in their New York

or Chicago warehouses.

They also represent all

major manufacturers of new

thermoforming machinery,

including rotary and single

station equipment. They can help you select the right

machine for your application and budget with over 75

years of experience in the thermoforming and routing

industry.

machine for your application and budget with over 75

years of experience in the thermoforming and routing

industry.

The CNC Router Store division of

PlastiMach is dedicated to providing a

selection of new and used CNC routers

to the plastics industry. They carry

routers from manufacturers such as

Thermwood, Motionmaster, Komo,

Multicam and others. The CNC Router

Store just added their CNC Technology Center in Indiana.

They now have the ability to demo and test some of their

used machines in house. They provide a comfort level for

the used buyer that never existed before.

For additional information contact PlastiMach

Corporation at 800-394-1128, Fax: 845-267-2825,

E-mail: tammy@plastimach.com, Web: www.plastimach.com.

|