|

Welding Spotlight

Welding Rod

Village Plastics Co. is offering the

largest selection of thermoplastic

and engineering grade

rods for many welding applications.

They have recently

introduced a new line of

biodegradable PLA rods

that are used in three dimensional

printing applications.

Village Plastics offers welding rod that is consistent in

both diameter and shape. They extrude 100% prime virgin

materials with real-time inspection by laser micrometers.

Customer-supplied resins are always welcome and

custom color matching is offered. Resin data sheets and

manufacturers certifications are available upon request.

Unmatched quality, largest inventory, on-time delivery

and exceptional customer service is what sets Village

Plastics apart from other welding rod manufacturers.

For additional information, contact Connie Snyder, Village

Plastics Co., 3375 Barber Road, Norton, OH 44203,

330-753-0100, Fax: 330-753-6610, E-mail: sales@villageplastics.com, Web: www.villageplastics.com.

Mini Extruder

You’re not going to have much luck trying to weld a tight

corner in a two-foot container with a three-foot extruder.

Get all the power of a real extrusion welder in a tiny package.

The MiniX is the smallest extrusion welder on the

market but it has no problem keeping up with the big

guys. Totally self contained, it has an integrated onboard

preheat air source and it is small enough to be used with

one hand. Its preheat tube can be repositioned for bottom

or side mount use.

The MiniX uses a real auger screw for

thorough material mixing and consistent

heat transfer - there are no air

pistons here. The extruder has a 2

lb/hr extrudate output, can achieve

temperatures up to 800° F, has

digital speed and temperature

controls and weights under 10 lbs.

PWT offers a full range of thermoplastic

welding and joining equipment

for the plastic fabrication market.

For additional information, contact Greg Yaple, PWT

International, 4261 Business Drive, Cameron Park, CA

95682, 800-635-6693, 530-676-3050, E-mail: info@pwtworld.com, Web: www.pwtworld.com.

New Handheld Welder

The TRIAC BT is the latest edition to Leister Process

Technology’s line of hand tools and is specifically designed

for indoor plastic fabrication applications.

Weighing 2.2 pounds, it is an extremely lightweight

device in its class, making it easy to handle and comfortable

to control. Its ergonomic, balanced-weight design makes

the TRIAC BT your perfect partner for precision welding.

The TRIAC BT comes in a sturdy carrying case that conains additional accessories, including three rapid-welding

nozzles and a replacement heating element.

Key features of the TRIAC BT

include: easy-to-adjust rotary

temperature control;

electronically protected

heating element;

extra strong,

0.2-

inch universal

nozzle; accidental start-up protection

in case of power interruption and a fine

mesh air filter that prevents clogs and can easily

be removed for cleaning.

For additional information, contact a Leister Authorized

Master Distributor: Assembly Supplies (Western U.S.),

800-694-1472, Web: www.hotairtools.com; Heely-Brown

(Southeastern U.S.), 800-241-4628, Web: www.heelybrown.com; Industrial Heat Sources (Midwestern U.S.),

800-635-0384, Web: www.industrialheatsources.com;

Malcom Company (Northeastern U.S.), 888-807-4030,

Web: www.malcom.com, STANMECH Technologies

(Canada), 888-438-6324, Web: www.stanmech.com.

Plastic Working Tools

ABBEON.COM provides

PlasticWorking tools and precision

instruments for industrial

needs. We are the source for

Thermocutter hot knives,

Forsthoff Hot Air Welding Tools

and Lufft Climate Monitoring

Instruments. In addition, hundreds

of other products are

available for R&D, manufacturing

and finishing applications.

The AZTC-20 compact Thermo cutter is a lightweight, durable hot knife for cutting foam,

thin plastics, fiber optics and synthetic fabrics. The ZETZ-24

Thermocutter is a heavy duty, constant heat cutter for

industrial applications like trimming solar panels or plastic

parts, grooving rubber, and automated cutting systems.

Forsthoff Hot Air tools include the Quick-SE with built in

blower, the Mini-Electronic and the Forplast Automatic

Overlap Welder. The handheld welders are used for overlap

welding of thermoplastic materials as well as with welding

rod for automotive repairs, tank construction, and sealed

flooring. Industrial uses of the Forplast Automatic Welders

include tarps, awnings, banners, tents, roofing and flooring.

Abbeon.com categories include Extrusion Welders,

Ultrasonic Welders, Web Cutters, Rope Cutters, Air

Nippers, Safety Knives, Saw Blades, Drill Bits, Strip

Cutters, Bending Equipment, Heat Sealers, Staking

Equipment, Meters, Regulators, and Air Blowers.

For additional information, contact Bob Brunsman,

Abbeon Cal, Inc. , 123 Gray Avenue, Santa Barbara, CA

93101, 800-922-0977/805-966-0810, Fax: 805-966-7659, E-mail: bbrunsman@abbeon.com, Web: www.abbeon.com.

Full Service Welding Supplier

WEGENER Welding LLC is an international supplier of high

quality welding, processing and testing equipment for custom

thermoplastic

fabrication and

repairs as well as

manufacturing, lining

and construction

applications. Their product

range includes: hot gas

(air) hand welding systems

and accessories; extrusion welding

systems; sheet butt welders and

benders; ac and dc spark testers; plastic

pipe band saws; pipe butt and socket fusion

machines and tools; specialty welders; filter welding/

embedding machines; training and education.

systems; sheet butt welders and

benders; ac and dc spark testers; plastic

pipe band saws; pipe butt and socket fusion

machines and tools; specialty welders; filter welding/

embedding machines; training and education.

Their recent move to a larger facility affords the necessary

space for a vast inventory of equipment, spares and

accessories, a

full repair

department as

well as a demo

and training

center.

Knowledgeable

sales personnel will be happy to assist you in determining

the best equipment type and model for the job at hand.

For additional information, contact Patty Zitkus,

WEGENER Welding LLC, 16W301 S Frontage Rd, Burr

Ridge IL 60527, 630-789-0990, Fax: 630-789-1380,

E-mail: patty@wegenerwelding.com, Web: www.wegenerwelding.com.

Welding Rod

New Image Plastics extrudes an extensive list of thermoplastic

and engineering high performance plastics for

welding rod. They also extrude customer provided resins

and offer additives to achieve a welding rod that will meet

your specific performance requirements, backed by their

manufacturer certifications. Don’t take a chance on a

failed weld!

For additional information, contact Jim Waring, New

Image Plastics Manufacturing, 241 Market Street West,

Canal Fulton, OH 44614, 866-789-WELD/330-854-3010, Fax: 330-854-6770, E-mail: plasticrods@aol.com,

Web: www.plasticweldingrod.com.

Hot Air Line

Seelye, Inc., a leading manufacturer of thermoplastic

welders for over 55 years, offers the Model 63, a very

popular welder for all levels of expertise. The temperature

on the SI-1005 and SI-1002 is adjustable using the air

regulator. Their 1167

includes a self-contained air

compressor and the only way

to adjust the temperature is

by changing the heating element.

The FC Series are for

people who want additional

control. They have a control

board that enables the technician

to have more control

over the temperature. By

adjusting the air flow on the

2001FC and the rheostat on the control board you are

able to achieve a more accurate temperature.

Unlike the 1167, the FCP’s temperature is adjustable

and is controlled by the rheostat on the control board.

The 1197CH is the welder for people who weld everything

from PP to UHMW. Like the FC Series, it has infinite

heat control settings and our patented “Cool to the Touch

Barrel.” This safety feature allows the welder to be

approximately 900° F at the tip while leaving the barrel

cool to the touch.

We are proud to announce that some of our most popular

thermoplastic welding tips are again available. We

have reengineered them to make them easier to use.

Please call us today to place an order for any one of our

thermoplastic welding tips including the famous: 1025

1028 Narrow body automatic speed tips, 1017 & 1018

Wide body automatic speed tips and 1024 Ribbon rod

automatic speed tips.

For additional information, contact Paige Bowen, Seelye,

Inc., 333C Enterprise Street, Ocoee, FL 34761, 800-258-2936/407-656-6677, Fax: 407-656-5244, E-mail:

seelyeinc@aol.com, Web: www.seelyeinc-orl.com.

High Speed Production Torch

The Laramy Torch is an electrically-heated, variable gas

flow torch of proven design, featuring 6 new interchangeable

“Located Heat” elements for welding temperatures

from 450-1300°F. This high-production torch offers complete versatility of

temperature and air or inert gas selection for production

and speed welding on all types of thermoplastics.

”Located Heat” elements are

ceramic, clad with stainless

steel for greater shock and

break resistance - plus added

protection against overheating

and burnout. ”Located Heat”

design concentrates heat output

at the tip end of the torch

for cooler, more comfortable

barrel temperature while delivering

higher gas temperature

at the tip from lower wattage

elements. 250, 350, 450 and 550-watt The elements are

readily interchangeable in a single small-diameter barrel for

fast changeover and simplified operation.

Two new high-temperature elements, 650 and 750

watts, make a heat range of 850-1300° F available for

speedwelding of Polypropylene and other high temperature

materials. These elements require use of a long barrel,

which is interchangeable with the shorter length barrel

used with the lower wattage elements.

The exclusive Laramy High-Speed Production Torch is

available as a basic welding torch, a complete outfit or as

a portable outfit.

For additional information, contact Sherry Stahler,

Laramy Products Co., P.O. Box 1168, Lyndonville, VT

05851, 802-626-9328, Fax: 802-626-5529, E-mail: laramy@together.net, Web: www.laramyplasticwelders.com.

Fusion Machine

McElroy’s new PitBull® 26 fusion machine is compact,

lightweight and rugged with the ability to butt fuse pipe

sizes from 2-inch IPS through 6-inch DIPS (63mm to

180mm) and all models come standard with a 6-inch IPS

insert set. With a

design similar to

the McElroy’s popular

PitBull 14, the

PitBull 26 features

McElroy’s patented

Centerline Guidance

System and a semiautomatic

locking

cam system that maintains force during the cooling cycle.

Contractors and pipeliners that already own McElroy’s

PolyPorter® and PolyHorse™ can continue to use those

tools with the new PitBull 26 for enhanced productivity.

For additional information, contact Tyler Henning,

McElroy Manufacturing, Inc., 833 North Fulton, Tulsa, OK

74115, 918-836-8611, Fax: 918-831-9285, E-mail:

thenning@mcelroy.com, Web: www.mcelroy.com.

Forming and Joining

Equipment

STANMECH Technologies Inc. specializes

in innovative, customer-focused solutions

that increase

profits,

advance

processes,

improve

efficiency,

save energy, reduce reject rates and give customers spectacular

results. They are experts in applications involving

plastics forming and joining methods including hot air

welding, extrusion welding and laser welding.

Their products include hot air hand tools such as the

TRIAC S, which is used worldwide by a wide variety of processionals,

ambient blowers, heaters, integrated hot air

blowers, automatic

welders,

and extrusion

welders such as

the WELDPLAST

and FUSION

family of tools. If

your company

uses processes

involving the

precise application of heat or air STANMECH Technologies

Inc. can help.

Their products include hot air hand tools such as the

TRIAC S, which is used worldwide by a wide variety of processionals,

ambient blowers, heaters, integrated hot air

blowers, automatic

welders,

and extrusion

welders such as

the WELDPLAST

and FUSION

family of tools. If

your company

uses processes

involving the

precise application of heat or air STANMECH Technologies

Inc. can help.

STANMECH Technologies is the master distributor for

Leister Process Technologies in Canada. Additionally, they

represent companies from around the world including

JetAir Technologies, LLC, Nex Flow Air Products Corp.,

and Secomak LTD.

For additional information, contact Paul Subject, STANMECH

Technologies Inc., 944 Zelco Drive, Burlington,

Ontario Canada L7L 4Y3, 888-GET-MECH/905-631-

6161, Fax: 905-631-1852, E-mail: info@stanmech.com,

Web: www.stanmech.com.

Versatile Welder & Rod

Drader manufactures the Injectiweld for

fabricating, prototyping and repairing

thermoplastics. The welder is

easy to use and produces high

quality welds. Two unique

features set the

Injectiweld apart from

other plastic welders. A

hot tip melts into the parent material eliminating the need

to scrape off the layer of oxidation before making a weld. Interchangeable tips increase the welder’s versatility,

allowing welds ranging in size from 1/16” to ½” in a single

pass. The second feature is its automatic feed system. This

allows control of the welder with one hand and use of the

other hand to hold the part being welded. High quality

welds are produced because the unit injects a molten shot

of welding rod into the weld zone with consistent, repeatable

pressure.

Welding Rod

Drader also stocks a range of welding rod and custom

manufactures numerous colors and types of plastic.

Customers can

send their own

resins to ensure

the welding rod

matches the

parent plastic

material exactly.

Drader's minimum

order remains 10

pounds. Their welding rod can be used with most fabrication

type plastic welders on the market today.

For additional information, contact Bruce Lecky, Drader

Mfg. Ind., Ltd., 5750 50th Street NW, Edmonton, Alberta

T6B 2Z8 Canada, 800-661-4122/780-440-2231, Fax:

780-440-2244, E-mail: blecky@drader.com, Web: www.drader.com.

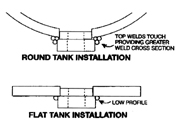

Stock Tank Couplings

Fabricated and molded tank manufacturers are finding

there is no longer a need for trips to a machine shop

because economical heavy-duty tank couplings, designed

for their application, are now available. IPW tank couplings

are easy

to install and are

sized to fit standard

hole saw

dimensions.

They have a

shoulder that

gauges installation

depth and

provides for

guaranteed square installations on flat surfaces. The

shoulder also provides better weld strength and easy

installation on round tanks. The shoulder and the low profile

design, combined with thick crosssections, practically

eliminate couplings shearing off from side impact. The

thick cross-sections prevent the splitting commonly seen

with FPT threaded couplings.

IPW features sizes ½” through 4” from stock in natural

HDPE, black HDPE, natural PP and black Type II (copolymer)

PP. Eurogray PP, PVDF, PVC and CPVC materials and

sizes 1/8” to 24” are now available on request. IPW provides

full couplings when interior piping is needed and for

vertical installations on domed tanks.

For additional information, contact Phil Holt, Industrial

Plastic Works, 6220 Enterprise Drive, Knoxville, TN

37909, 800-966-1460, Fax: 865-637-4540, E-mail:

sales@ipw.us.com, Web: www.ipw.us.com.

Welder Training

The Plastic Welding School has expanded its curriculum to

include on-site training at the customer’s facility. This is

very beneficial as the employees work with the company’s

tools, in the company’s environment and with the company’s

material.

The spring classes will begin soon and enrollment is limited

to eight per class. All three courses: the two day introductory

class, the three day including extrusion welding,

and the 5 day advanced course will be taught at all three

of their locations and are hands-on.

For additional information, contact Larry Rowold, The

Plastic Welding School, 1010 Vermont Ave, The Villages,

FL 32159, 352-259-7103, Cell 630-319-3480, E-mail:

larry@rreworld.com.

|