|

Today's Multiwall PC Technology Integrates Aesthetics, Sustainability and Economy

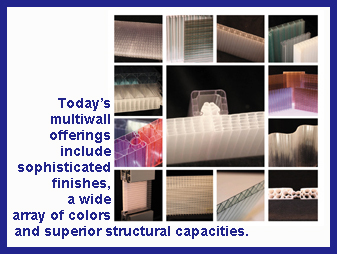

Today’s multiwall offerings include sophisticated

finishes, a wide array of colors and superior

structural capacities.

Few glazing materials

have progressed as far

and as fast in recent

years as translucent multiwall

polycarbonates. Advances in

thickness, texture, tint, thermal

value and performance,

combined with design versatility,

make this daylighting

alternative an increasingly

preferred element of sustainable

building.

Few glazing materials

have progressed as far

and as fast in recent

years as translucent multiwall

polycarbonates. Advances in

thickness, texture, tint, thermal

value and performance,

combined with design versatility,

make this daylighting

alternative an increasingly

preferred element of sustainable

building.

The industry saw a 5%

increase in 2009, in the

middle of a major recession.

The multiwall market estimates

an 8% increase in

2010. There are sound reasons

for this:

Green building is now the

norm; daylighting is an

increasingly important component,

and many applications

don’t require a view.

Traditional direct daylighting

with glass can create glare, hot

spots and solar gain, which in turn create uncomfortable,

unproductive environments and high operating costs.

Diffuse daylighting provides the benefits of natural lighting

– and projects it 33% deeper into a space – as it eliminates

these disadvantages.

Structural capacities allow for engineering systems that

can withstand the impact of hurricane-velocity winds and

will pass large-missile impact tests.

Multi-wall sheet products can integrate with other new

technologies that enhance performance, especially energy

efficiency.

Improvements in weatherization and fire safety have

made multiwalls a more attractive alternative in commercial,

industrial, educational and government facilities.

Many carry a CC1 – Class A fire rating. Most have UV protection

co-extruded into the sheet, preventing discoloration

and light loss.

Architects and designers are now appraising this previously

overlooked material and appreciating what they see

in aesthetics, energy efficiency and economy – often with

initial costs one-third to

one-half less than traditional

alternatives.

While three primary suppliers

provide the resin

worldwide for multiwall

sheet extrusion, each

extruder enhances the

product with its own, often

exclusive, features. Finishes

vary widely. The slick, high

gloss of previous multiwalls

has been replaced with textured

finishes in hammered

crystal and satin mattes.

Colors range from standard

blue, green, bronze, opal

and clear to lavender, red,

yellow, gray and more.

Specialties include sheets

with a structural “rippling

wave” effect. Thicknesses in

6mm to 40mm+ provide Uvalues

down to 0.19 with Rvalues

up to 5.26. Light transmission

can reach 92%. And

the material is 100% recyclable.

Exceptional energy efficiency can be achieved by filling

the sheet’s cells with a new translucent aerogel that doubles

the thermal value, while maintaining high light transmission.

Another new technology in spectrally selective

coatings places a transparent film in the cells’ interior,

blocking up to 95% of infrared rays, 99% of UV rays and

up to 85% of solar energy, while maintaining light transmission

to 65%.

Design versatility is major factor in multiwall’s growing

popularity. The sheets, which can be ordered up to 39’ in

length, cold-form easily in dramatic curves. The translucency

enables a designer to use backlighting, including

low-voltage LED arrays, to create environments that

soothe, excite and inspire occupants. And the lighter

weight in this shatterproof material allows for larger spans

with less support required.

Design versatility is major factor in multiwall’s growing

popularity. The sheets, which can be ordered up to 39’ in

length, cold-form easily in dramatic curves. The translucency

enables a designer to use backlighting, including

low-voltage LED arrays, to create environments that

soothe, excite and inspire occupants. And the lighter

weight in this shatterproof material allows for larger spans

with less support required.

Today’s translucent multiwall technology lends itself to a

wide range of applications from skylights to vertical glazing

of all types to canopies to interior walls.

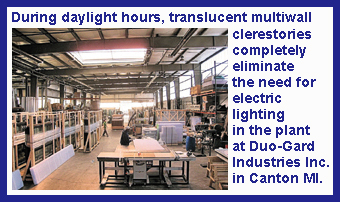

Industrial applications are just one

prime example. When Duo-Gard

Industries Inc, located in Canton

Michigan, updated its headquarters

in late 2009, it replaced 13-year-old

multiwall clerestories with today’s

advanced technology. The company

is a leading innovator in developing

high-performance translucent daylighting

systems for the architectural

market.

“We practice what we preach,” said

David Miller, Duo-Gard’s President.

“Today’s multiwall performance and

aesthetics far outpace yesterdays.

Our previous system required a layer

of translucent thermal foam to

achieve the desired insulation along

with light transmission. This created

some problems that we wanted to

eliminate.”

Duo-Gard selected a 20mm

tongue-and-groove multiwall glazing

from Co-Ex Corporation for the

replacement. Now the 20,000

square foot facility sports a clerestory

12’ high by 275’ long on its south

and west elevations. The west wall

includes a 20-foot-wide section of

operable panels for ventilation.

Miller said the mullionless tongueand-

groove system in the opal tint

chosen enhances the facility’s facade

as it allows 47% visible light transmission,

and the 20mm thickness

carries a 0.35 U-value, R-4 thermal

rating. “This gives us more light –

usable, diffused daylight - with the

same thermal value as before,” he

said, adding that the plant’s long

banks of metal halide lights are never

on during days with adequate sunlight,

resulting in a 33% - 50% savings

in electricity. Installation of the

tongue-and-groove system took only

7 days instead of an estimated 11.

Along with the advantages of

today’s multiwall polycarbonates

come some cautions. The material’s

UV-protected surface must face out.

A multiwall system must be dryglazed.

Because it has a higher coefficient

of expansion than glass, it

requires special framing systems

engineered to accommodate this factor.

Multiwalls must “float” in the

frame: standard framings for glass

grip too tightly to allow this.

Although it’s virtually shatterproof,

the material can be scratched, so

specifiers need to choose applications

carefully and select an appropriate

surface texture. Because of the

material’s diversity in performance

and aesthetics, it’s important to be

sure the choice of material effectively

suits the proposed application.

Properly evaluated and applied,

today’s multiwall polycarbonate technology

gives those involved with the

green building movement an opportunity

to combine exceptional aesthetics,

energy efficiency and economy

in daylighting.

For more information, contact

Kurt Glazer, CO-EX Corporation, 5

Alexander Drive, Wallingford, CT

06492, 800-888-5364, Fax: 203-679-0600, E-mail: info@co-excorp.com. Web:

www.co-excorp.com.

|