|

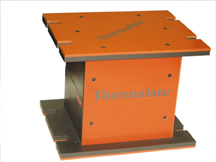

Platen Insulation Product Line

Haysite Reinforced Plastics has recently advanced the properties of its Thermalate® and Heatmeiser® line of compression molded platen

insulation sheet products.

Comprised of

uniquely formulated

fiberglass reinforced

thermoset polyester

composites, the series

delivers superior energy

efficiency, temperature

control, durability and is

an asbestos-free solution

for high temperature mold and platen thermal press manufacturing

applications.

When installed between the platen and mold, the series

offers superior compression versus asbestos, mica, calcium

silicate and other high pressure laminate insulation

alternatives (G-3 / G-7 / G-11).

The unique combination of these

thermal performance properties control

and minimize the transfer of heat

to the production press; therefore

reducing the costs associated with

excessive utility usage, machinery

wear/breakdown and stability/uniformity

of product quality. Major industrial

market applications for Ther malate®

and Heatmeiser® include curing presses

for tires, golf balls, road repair and

food processing; and assorted compression

and injection molders.

Requiring no maintenance and

designed to operate at temperatures

up to 550°F, the thermal insulation

sheet series’ high compressive

strength will not take a compressive

“set”; causing mold alignment problems

when subject to extremely high

molding pressures.

Tough and durable, they will not

crack or break easily during mold

setup or tear down and are more

durable than mica or concrete

asbestos materials. Additionally,

they resist oils and fluids where

other more absorbent insulators,

such as concrete asbestos, can deteriorate

or alter their thermal conductivity.

Notably, Heatmeiser’s composite

thermal properties are a breakthrough

for mold applications providing

even more advanced thermal

conductivity and energy savings.

Standard stocked sheet sizes: 36" x

72" and 48" x 96", 48" x 60" is available

upon request with thickness

available from 1/4" to 2". Haysite

implements a unique compression

molding process that saves time in

production as all processing elements

are completed in a one-step proprietary

method. The molded sheets are

then sanded on both sides. A stateof-

the art micro-sander is utilized to

achieve very tight thickness tolerances

in the final process of production

(as tight as +/- 0.002).

For more information, contact

Anthony Lignetta, Haysite Reinforced

Plastics, 5599 New Perry Highway, Erie,

PA 16509, 814-868-3691, Fax: 814-864-7803, E-mail: alignetta@haysite.com, Web: www.haysite.com.

|