|

THERMOFORMING: Cut Sheet Pressure Forming

A Look Into Thermoformings' High Pressure Forming

Pressure Forming

Pressure forming applications

have been rapidly increasing for

two main reasons. First, the

process can match the cosmetics

of injection molded parts and get

them to market quickly without

high mold costs and the long

lead-times associated with injection

molding. Second, the process

is being utilized to improve

and or upgrade parts that have

been traditionally vacuum-formed.

Pressure forming can

achieve better detail on the mold

surface of the sheet, hold closer

tolerances, have better material

distribution and less residual

stress when compared to standard

thermoforming.

Pressure forming enables designers to achieve high-end

products with sharp, crisp lines, zero radii and even zero

or negative draft angles. Engineers can include undercuts,

flanges, ribs and louvers in their

designs and still be assured that

the final products’ detail will be

kept. Pressure forming provides

aesthetic appearances, structural

integrity and more design flexibility

when solving part detail

dilemmas.

This process of thermoforming

typically uses female molds:

these molds can have multiple

textures, smooth areas and even

company logos all on the same

mold. If the final product requires

definition on the inside, the mold

would need to be male. For this

reason, converting designs from

other processes can be economically

advantageous.

Process Sequence

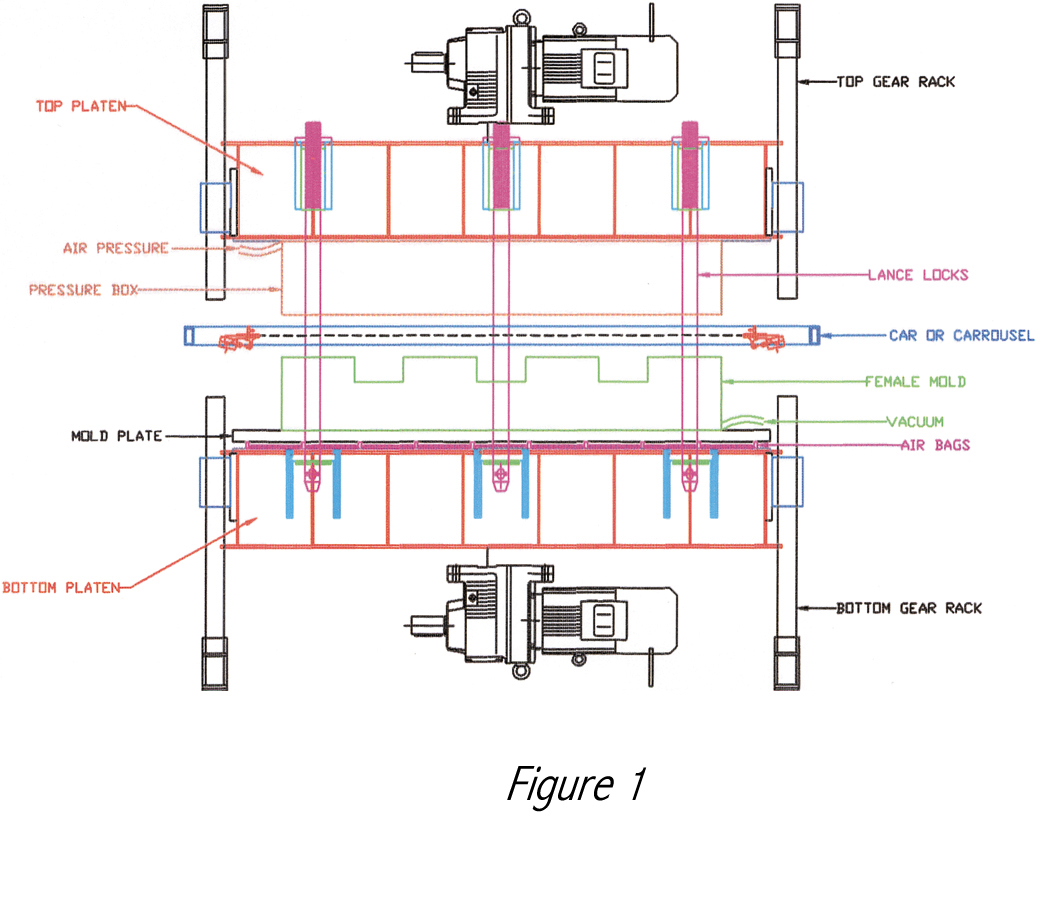

In this process, the sheet is heated to forming temperature,

the hot sheet is transferred to the forming station,

the upper mold (or pressure box) and lower mold are

brought together and compressed air is introduced

through the pressure box pushing the material against the

mold so more complex details of the mold are picked up

to achieve higher part definition (Figure 1).

Process Molds

Pressure forming molds are typically more expensive

than standard thermoforming molds for several reasons.

Pressure forming molds require a pressure box or second

mold half depending on the exact application. The mold

also needs to be water cooled aluminum in order to withstand

pressures and assure forming temperature of mold

surface. Due to these mold features and process sequence,

another advantage to pressure forming is introduced.

With the additional contact pressure of the forming

material with the mold surface the process allows more

control over cooling of the formed part resulting in less

stress and faster cooling times. Tooling deflection must

also be calculated to the amount of pressure that will be

applied, which can

increase mold pricing.

More intricate

products may require

molds with

articulating pieces.

Typical applications

include; automotive

panels, computer

housings and

bezels, cases, medical

housings, exercise

equipment, instrument

panels,

light lenses, television

backs, appliances,

aircraft interiors

and many more.

Process Materials

Generally speaking, all materials which can be thermoformed

can be pressure formed. However, as might be

expected, some are more suitable than others. Amorphous

polymers such as ABS, Polystyrene and acrylic are

ideal for both thermoforming and pressure forming in giving

high viscosity melts over a broad temperature range.

Polymers having a mixture of crystalline and amorphous

characteristics such as polypropylene and polyethylene

are intermediate in performance but are being molded

successfully. A further

consideration is that

certain materials, such

as polycarbonate, are

highly hydroscopic and

must be thoroughly

dried before thermoforming.

This is not

necessarily a problem

but it does add to the

expense of processing

the material.

Given the wide range

of materials that can

be pressure formed,

normal plastic design

criteria apply. The

material selected must

fulfill the specific requirements

of the part in terms of aesthetics, fitness for

purpose and compatibility with its expected environment.

Last but not least, the part must also meet economic

goals.

Types Of Pressure Forming:

Air-Assist Pressure Forming

Air-Assist pressure forming is referred to as pressure

forming without locking the platens. Air assist pressure forming is defined as the amount of detail in a part that 30 psi will

create (using 16 psi from air pressure in addition to 14 psi from

vacuum {29hg}). This is typically only done on machines with

hydraulic or motor driven platen drives. Without locking the

platens, machines are only designed to hold the amount of pressure

created by the cylinder or brake-motor before the tools separate,

releasing the air pressure.

High Pressure Forming Platen

Lock-Up Pressure Forming

Air cell lock up, high pressure forming is done with machinery

specifically designed for this process. This technique extends both

platens, locking them to each other then inflating air cells under a

floating plate which can be attached to either the

bottom or top platen. This method provides the

force necessary to create a high pressure seal.

High pressure forming is the amount of detail in a

part that 60 psi will create using 50 psi from air

pressure and 10 psi from vacuum. Common pressures

are 35 psi to 60 psi, however in some applications

utilizing large parts or highly engineered/

reinforced materials, higher pressures

may be required.

Compression Forming

Compression forming is the thermoforming

process utilized for creating high detail on two

sided parts, achieving an exact finished gauge and

creating a high pressure knit between two mold

surfaces (twin sheet forming). Most applications

require locking platens. This is determined by

sheet gauge and material type. In single sheet

forming, the part will be formed by the bottom

tool compressing the material against the top

tool. This requires matched tools.

Pressure Forming VS Injection Molding

The pressure forming market is continually

increasing from year to year and does hold several

advantages over injection molding.

Tooling can be up to 80% less for upfront tooling

expenses on pressure forming versus injection

molding. The significant savings comes from pressure

forming molds only needing to be machined

aluminum or cast aluminum, rather than

machined steel. Also, most pressure forming

molds only require one mold half and a pressure

box instead of two matched molds that are

required in injection molding.

Costs are usually much less due to tool amortization,

especially when comparing limited production

quantities. These advantages become even

more significant as the size of the parts become

progressively larger. Lead times and deliveries

are much faster, with lower prototyping costs,

therefore allowing for more time on final design

modifications. With quicker prototyping capabilities,

pressure formers can ensure maximum flexibility

and even visibility of the product definition

before finalized. Pressure forming can also eliminate

negative conditions that are common to the

injection molding process; such as ejection marks,

gate marks and porosity.

Written by Michael P. Alongi, Sales Director for MAAC Machinery Corp., manufacturers of a wide range of cut-sheet thermoforming machinery.

For more information, contact MAAC Machinery

Corp., 590 Tower Blvd., Carol Stream, IL 60188,

630-665-1700, Fax: 630-665-7799, E-mail:

sales@maacmachinery.com, Web: www. maac-machinery.

com.

|