|

THERMOFORMING: Cut Sheet Thermoforming

Reduce your downtime;

increase your up-time –

with NEW TECHNOLOGY

and Quick Change Features!

As economic times change,

competition increases,

customers demand quicker

deliveries, or end-users push

for better products and pricing,

thermoformers are being forced

to step up to the next level. Our

industry is changing rapidly,

moving towards higher levels of

sophistication. Whether you are

a small or larger company, an OEM, a custom former or

run your own proprietary products, there are several ways

to reduce your downtime and start gaining efficiencies

with all the new advancements and innovations in thermoforming

machinery.

From quicker clampframe and mold changes to elaborate

machine controls, thermoformers who are set up

most effectively are proving to be the most profitable.

Today’s thermoformers need to set their goals much higher;

reduce mold changeover to

fewer than 15 minutes, reduce

clampframe changeovers to

fewer than 5 minutes (per station),

and look to change all

machine parameters in seconds!

Clampframe Changeover

Clampframe changeover has

been one of the leading factors

causing machine downtime. A routine clampframe change

can take up to 4 hours depending on how many stations

a machine has. A clampframe change typically consists of

replacing the short clampframe segments for every different

sheet width. Not only do thermoformers have to buy

all these different size short frames, they must store and

maintain them. One of the newest items available,

Adjustable Clampframes, have been the single hottest

items to hit the machinery market. You no longer need to store and replace different lengths of clampframe

for the diverse sheet sizes required.

Adjustable

clampframes offer the ability to vary the length

of the clampframes without having to add or

remove clampframe sections from the machine

and with no tools required. Not only can you

change these frames in under 5 minutes, but you

can also document the position of these

clampframes and easily return them to the exact

position the next time the product is run. This

would also require a repeatable mold position.

Adjustable clampframes are continually proving

to save anywhere from 1 to 3 hours of downtime,

(per mold changeover) depending on what type

of machinery or how many stations the equipment

has.

Adjustable

clampframes offer the ability to vary the length

of the clampframes without having to add or

remove clampframe sections from the machine

and with no tools required. Not only can you

change these frames in under 5 minutes, but you

can also document the position of these

clampframes and easily return them to the exact

position the next time the product is run. This

would also require a repeatable mold position.

Adjustable clampframes are continually proving

to save anywhere from 1 to 3 hours of downtime,

(per mold changeover) depending on what type

of machinery or how many stations the equipment

has.

In addition to speeding up clampframe

changeover time; look to reduce your sheet

sizes. Some of the older or poorly designed

clampframe systems require up to 2” of material

to be clamped in their frames. This should be

kept to a minimum of no more than a 1/2” of

material per side.

Mold Changeover

Mold changeovers are another one of the

leading factors causing machine downtime.

Since most molds are unique, are built by different

suppliers, or are moved from company to

company, most thermoformers end up with a

large quantity of different mold bases and mold

configurations. The key to quick mold change is

to make all design factors on each mold common

to each other, such as: utility location,

mold base heights and general mold base construction.

If this is not possible or cost-effective

then consider using a stand alone – common

mold base.

With uncommon mold bases, the use of steel

plates with precisely spaced bolt patterns or aluminum

plates with T-slots have been most popular.

Molds are then secured using either a hold

down fixture or simply by bolting the mold base

to the platen. This may still be the most versatile

system for some thermoformers.

With a stand alone – common mold base,

thermoformers can utilize several mold bases

or just two mold bases. The expense of

changing all your mold bases may not be

cost-effective, but the use of only two keeps your expenses minimal. This allows one mold (attached to the 1st

mold base) to be run in production while another mold is being

secured to the 2nd mold base outside the machine. This can even

be taken a step further by having all of the utilities connected

outside the machine.

The actual design of the mold base is unlimited but needs to be

designed with maximum flexibility in mind. With a common mold

base you can then look to automate the changeover process even

further. You can use scales, locating pins, locating cones or back

stops to consistently locate the mold base to the platen. You can use

hand clamps or automatic clamps controlled through the machine to

secure your base down to the platen.

Of course this is easier said than done, and other factors must be

considered, but it usually is just a matter of discussing a few different approaches to determine what best fits your company. The

technology is here and has been taken as far as fully

automating mold changeovers. As a result with any of these

systems you will start realizing more machine up-time.

Adjustable Lift Table Tops

On most high sheet line rotary machines and/or

machines with lift tables, clients need to make different

size boxes or use boards to assist holding and aligning

sheet before it is loaded into the clampframe. Once these

boxes and/or boards are not being used they must be

stored away for future use. This has created the development

of an adjustable lift tabletop which is custom built

and mounted to the lift table. This allows quicker set-ups

by avoiding the need to replace tabletops for every different

sheet size. These tabletops feature four-way adjustments

via clamping handle levers. No tools are required.

This allows changing of the table top in seconds.

Machine Control Changeover

Machine controls should be

looked at closely, as they are one

of the most powerful components

associated with quick changeover.

Machines with simple controls are

limited, and typically more time

consuming which causes inefficiencies.

Machines with elaborate controls

are able to be set up much

quicker, offering maximum flexibility

and maximum efficiencies.

Machine controls should be

looked at closely, as they are one

of the most powerful components

associated with quick changeover.

Machines with simple controls are

limited, and typically more time

consuming which causes inefficiencies.

Machines with elaborate controls

are able to be set up much

quicker, offering maximum flexibility

and maximum efficiencies.

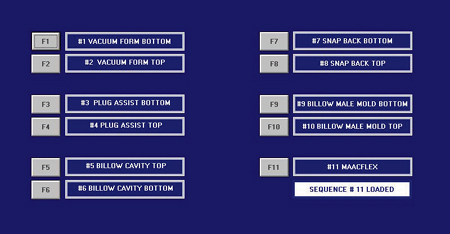

Computerized controls offer numerous benefits.

Replacing relays and timers, manual buttons and switches

with flat panel touch screen interfaces and innovative software

allows thermoformers the ability to change every

machine parameter within seconds. This eliminates the

manual process of setting up different machine sequences,

adjusting limit switches, opening and closing valves, setting

oven heat configurations and even reading job setup

sheets. Below is a brief description of the many items now

being fully controlled and automated through new technology

and new control systems:

Limited or Basic Controls

Less process control, higher scrap rates, no reliability,

no repeatability, longer setups.

Elaborate Controls

Most process control, less scrap, repeatability, quicker

setups.

Preprogrammed Forming Techniques are absolutely

necessary. Instead of having to physically program the

entire sequence of the machine during the initial setup

(which can take a great deal of time), your machine

should have pre-programmed forming techniques. This

means setup personnel can choose from a selection of

different preprogrammed sequences, eliminating the

need to program all functions of an entire machine

sequence every time the job is run.

Preprogrammed

forming techniques cover over 90% of the thermoforming

work today and only take seconds to set up. In addition,

the newer control systems offer the ability to modify

these preprogrammed forming techniques to create

your own proprietary methods if a challenging application

is introduced.

Platen positioning and motor speeds are now controlled

through the control system. Gone are the time-consuming

days of manually adjusting collars or limit switches. Today

motor driven platens are typically equipped with encoders

for fast setups, repeatable speeds and precise positioning.

The encoders are then interfaced into the control system

with real time graphic emulation of platen movement displayed

on screen. The platen settings are then stored in

the controller with each job for future recall. Although this

has been available for quite some time, it is being taken

further every year. Encoder driven platens no longer

require homing or zeroing and the machine may be turned

off without losing platen home position.

Vacuum and air valve positioning typically requires

setup personnel to manually adjust vacuum and/or air ball

valve settings. On more complex products these settings

can be crucial to forming an acceptable part. Too much

vacuum can cause improper material distribution on certain

applications and not enough vacuum can cause the

material to not fully form to the shape of the mold. New

technology now offers computer controlled valves, which

provide maximum consistency and repeatability with positioning

increments from 0-99%. With computer controlled

valves, all vacuum and air valve settings are entered into

the control system and saved with each job for future

recall. By saving and recalling valve positioning with every

job, computerized valves eliminate the manual guess work

of finding the correct vacuum and/or air valve openings,

which in some cases can eliminate hours of fine tuning.

Automatic lance adjustments are also completely programmable

through the control system. If pressure forming

or twin sheet forming is your company’s focus, adjusting

the lances (or bayonets) adds on to your setup time.

Typical pressure forming applications require setup personnel

to manually adjust the bayonets when the mold

lock-up heights change. This can be a lengthy process

since setup personnel must physically measure and position

anywhere from 4-12 lances (or bayonets) for each setup.

There is also room for error when manually adjusting,

as each bayonet’s positioning should be exactly the same

or damage can be caused to the machine and/or molds.

Automatic lance adjustment was created to eliminate the

manual process of setting up the lances, which on some

machines can take up to 4 hours. New pressure forming

machinery fitted with automatic lance (or bayonet) adjustment

assure: repeatable, accurate and fast changeovers

within seconds. The lock up height is automatically set by

finalizing both platen positions, simply activate and the

lances will self adjust. The positioning is then stored and

saved for each job for future recall.

In addition to faster changeovers, new technology is

offering even more features to gain efficiencies. Between

elaborate diagnostic systems and automatic lubrication

systems, machinery manufacturers are continually looking

to add to the thermoformer’s bottom line. Diagnostic systems

are eliminating lengthy trouble shooting procedures

and automatic lubrication systems are reducing the maintenance

required and increasing the life of the machinery.

As machines get smarter, faster and are equipped with

these types of quick change features, thermoformers who

lag behind in technology will find it much harder to compete

and be successful. Many thermoformers are acquiring all of

this technology in their new machinery. Some have even

found they can meet their increased production requirements

with these new technologies after getting rid of older

machinery. Meaning, one new machine has replaced the

need and production requirements of two older machines.

Clients who are investing in this machinery are gaining

efficiencies; they are making better products faster, more

repeatable, reducing scrap rates, reducing maintenance,

reducing personnel and of course adding to their bottom

line! In years to come those who do not start adapting new

technology will no longer be competitive, as today’s thermoformers

are taking large steps to leap ahead in technology.

Learn and investigate, start planning to eliminate

all the old mind sets and inefficiencies. As labor rates

increase and material rates increase, the market will continue

changing. Ask yourself “How will I compete?”

Written by Michael P. Alongi, Sales Director for MAAC

Machinery Corp., manufacturers of a wide range of cutsheet

thermoforming machinery.

For more information, contact MAAC Machinery Corp., 590 Tower Blvd.,

Carol Stream, IL 60188, 630-665-1700, Fax: 630-665-

7799, E-mail: sales@maacmachinery.com, Web:

www.maacmachinery.com.

|