|

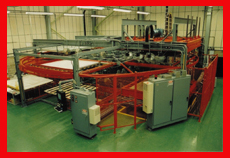

THERMOFORMING: The Rotary Advantage

The Rotary Thermoforming

Machine has seen

constant improvements

and continues to be the

fastest standard sheet fed

thermoforming machine manufactured

in the country. As it

continues to gain popularity,

it is persistently being adapted

to gain more and more

advantages over other types

of sheet fed thermoforming

machines. The rotary is mainly

utilized for mid to high volume

production of parts,

which is its single largest

advantage.

The latest rotaries

offer many additional advantages that allow users to gain

a competitive advantage, not only by having high production

capabilities but much more. The additional benefits

can be overlooked by companies not aware of them,

whether they are utilizing a rotary or competing with one.

The improved designs and technology implemented in the

rotary have made it a much more versatile machine.

More Parts Per Hour / Energy Savings

Rotaries guarantee more capacity and faster cycle

times while utilizing less electrical consumption per part

when compared to a single station or shuttle type

machine. This is due to the fact that a rotary machine

continuously has a sheet in the oven, as all stations are

being utilized simultaneously. In a three station rotary,

after unloading a finished part from station 1, the next

sheet is loaded back into the station, meanwhile station

2 is being heated and station 3 is being formed. This

allows the rotary machines to be capable of producing

product with 1/3rd the amount of oven energy that a single

station would require. While utilizing a rotary, the

cycle time is either dictated by the heating time or cooling

time, whichever is longer. The constant is 2.8 to 3

times the parts per hour output with oven electrical consumption

equal to a single station. This makes the rotary

machine more energy efficient. With faster cycles, less

machine time is needed, allowing companies to spend

fewer hours, use less energy per part and less labor while

at the same time, gain machine time and capacity.

More Consistent

and Repeatable

The Rotary machine can

ensure high daily outputs

regardless of the operator’s

influence. The machine’s cycle

time is not dictated by the

time it takes the operator to

load and align a sheet and

unload a finished product like

it is on a single station. The

operator running a rotary is

required to load and unload

within the products cycle

time, therefore allowing thermoformers

to be more constant

with higher productions as well as more consistent

with finished products.

Since a rotary cycles constantly, based on a pre-set cycle

time, the atmosphere within the oven also remains very

consistent. This oven consistency makes the rotary a

favorable machine with some of the new applications and

materials that require tight and repeatable temperatures,

such as paint films. Since materials are becoming much

more advanced, the oven consistency provides a more reliable

oven, therefore making it much easier to hold tighter

tolerances.

The finished part consistency of the rotary is beginning

to force some of the lower volume applications to be utilized

exclusively in this type of machine.

Although most thermoformers utilize water-cooled aluminum

molds when running a rotary machine, shorter

runs with ceramic, resin, fiberglass or non water-cooled

molds are still possible with a rotary. The limiting factor

when using a non temperature controlled mold is overheating

it. The machine can be slowed down to accommodate

this type of situation, but cooling the tool will be

the deciding factor on the cycle time.

Furthermore, the new rotaries are programmed to allow

formers to use a skip frame technique, which will form a

part every other cycle, allowing the mold additional time to

cool. By not loading a sheet into station one; the machine

will remember not to perform any function when that station

reaches the forming area. Although this may not be an

ideal procedure, formers with high and low volumes can still adapt to their marketplace and utilize the consistency

of a rotary. You can also simply slow down the rotary, or just

apply the right amount of cooling to your tool, depending

on your specific applications.

With the higher demand of lower volume rotary applications,

machine manufacturers have quickly implemented

features that allow machine changeover times to be drastically

reduced. Three station rotaries can be changed

over in less than 35 minutes with the use of adjustable

clamp frames, mold centering and securing devises and

the latest in machine controls. Preheated tooling is also

becoming more common for even faster part to part

changeover times.

Several advantages of recent model rotary machines are

apparent with machines that have a high sheet line and lift

table system for semi-automatic bottom loading and unloading

of parts. Older rotary designs that have low sheet-lines

and are top loaded manually do not provide as many advantages,

nor do traditional single stations or shuttles that are

toploaded.

Safety

Safety is a primary benefit of the overhead design of a

high sheet line machine with a semi-automatic loading

devise or lift table. This feature removes the possibility of

placing hands into the clamp frame when loading and

aligning sheets of plastic. It also reduces the risk of touching

hot clamp frames and machine components that cycle

through the oven. This design also

greatly reduces the risk of personnel

walking into the rotating carousel. As

most thermoformers running single

stations and top load machines know,

burns, pinched fingers or any type of

injury can get expensive.

The “no pit design” also eliminates

the need for personnel to enter a pit

for maintenance purposes, which

helps to reduce the risk of an accident

occurring. The “no pit design” allows

for a quick and easy installation and

gives the flexibility of moving the

machine around your facility instead

of being forced with a permanent

machine location due to a platen pit

requirement. The “no pit design” also

tends to improve housekeeping of

your facility.

Floor Space

Floor space is a valuable item in

today’s thermoforming facilities.

Another reason the high sheet design

is preferred, is it creates additional

floor space for loading, unloading and

trimming. With room for a skid of

material (usually on the right side of

the load/unload station), loading and

unloading can be accomplished within

the perimeter of the machine. The high sheet line design

allows you to incorporate the vacuum reserve tankwithin

the machine’s parameter, therefore eliminating the need

for any additional floor space.

Easier on the Operator

The ergonomic high sheet line design, coupled with the

lift table, eliminates the need for an operator to bend over

to load and unload material. With a stack of material to

the right or left of the lift table, an operator can ergonomically

slide sheets onto the lift table instead of carrying or

lifting sheets. Since the lift table also retrieves the formed

part when the cycle is complete, the operator can also

select what height he wishes to unload the part, once

again making it easier on the operator.

A larger selection of machine operators can also be

considered to operate these machines as they no longer

need to have the 3-foot arm span that is typically needed

to reach over the clamp frames to load any top load style

of machine. Since lifting is kept to a minimum, the operator

can also be less physically fit and still keep up with

production.

Since the operator has less physical stress and can load

much quicker, additional free time becomes available.

This can allow operators to do better secondary operations

or additional operations such as: quality assurance,

trimming or even tweaking the machines parameters for

more efficiency.

Smaller Sheet Sizes and Lower Scrap Rates

Loading sheet is more precise by the use of a lift table

and sheet guide system. Sheet material is easily positioned

onto the lift table; adjustable stops are provided for

repeatable positioning of sheet into the clamp frame.

Sheets can be loaded much more accurately and repeatably,

which nearly eliminates sheet “pullouts” or clamping

of unaligned sheets, which are two major causes of

increased scrap rates. On low sheet line, top load

machines the operator is responsible for the continual

alignment of loading sheets accurately, therefore allowing

for more error or more scrap.

The precision lift table in conjunction with good clamp

frames requires only the minimum blank size of material.

By loading sheets more accurately and repeatably you can

reduce the material blank size by 6% to 12%. With low

sheet line, top load machines most formers oversize the

starting dimensions of their sheet to accommodate the

operator on loading and aligning of the sheet. They have

found the larger sheet size reduces operator error and

lowers scrap, but the bottom line is it still adds cost to use

a larger sheet size.

The thermoforming manufacturing world is now being

forced to use the most efficient procedures and equipment

in order to maintain its competitive edge in today’s marketplace.

Lower labor costs, lower material costs, lower

energy costs, shortest changeover times and improved

part-to-part consistency are all the main reasons our marketplace

is making changes and why the latest rotary

technology is being further implemented and utilized.

For more information, click on the Author Biography link at the top of the page.

|