|

THERMOFORMING: Advances in Thermoforming Machinery

As the Thermoforming Industry continues to grow,

and new challenges are presented, today’s thermoforming

machinery technology has become much

more advanced. The benefits to purchasing new machinery

will continue to outweigh those of used or retro-fitted equipment.

As the technology advancements have greatly

improved in all aspects of today’s machines, you simply cannot

cost-effectively bring an old machine up to today’s standards.

Below are some of the more recent advancements or

higher standards being implemented into today’s machinery.

These are just a taste of over 50 major improvements

and additional capabilities of machinery and process potential.

Some are more application-specific, but all can greatly

benefit today’s thermoformer. With more process control

than ever before, and more options and capabilities, new

machinery with its corresponding technology is truly

becoming one of the thermoformers greatest assets, and

certainly an engine that drives competition to the next level.

Controls

Machine controls are continually progressing. Proven

machine control software has now been implemented for

over 20 years, allowing machine manufacturers to provide

an unlimited range of functions and capabilities all at the

palm of your hand. As more than 100 sheet fed thermoforming

machines are being built every year, more and

more ideas are requested and more and more improvements

are implemented.

over 20 years, allowing machine manufacturers to provide

an unlimited range of functions and capabilities all at the

palm of your hand. As more than 100 sheet fed thermoforming

machines are being built every year, more and

more ideas are requested and more and more improvements

are implemented.

The latest technology in computerized machine controls offers

huge benefits. Replacing relays and timers, manual buttons, and

switches with flat panel

touch screen interfaces

and innovative software

allows thermoformers the

ability to change every

machine parameter within

seconds. This eliminates

the manual process of setting

up different machine

sequences, adjusting limit

switches, opening and

closing valves, setting

oven heat configurations,

setting pressures and

even reading job setup

sheets. Not only can previously

programmed jobs be brought up and machine parameters

changed within seconds, new technology is also reducing initial

setup times and allowing the constant tweaking of jobs to

make them faster and more user-friendly.

Massive input and output diagnostic systems are now

standard, including oven zone burn out displays that allow

for the quickest trouble shooting and the least amount of

down time. Software is smarter, with built in alarms and

warnings that will notify the operator prior to potential

human error. Help files, job note sections, machine history

reports and statistical process control reports can be

viewed on screen or easily printed. Multi-level security

systems are built in to restrict or limit the control each

operator is granted. Phone modems for remote support

and program updates are standard, which greatly reduces

costly service technicians and machine down time. All this

comes as a result of ongoing R&D and ongoing feedback

from our market place. As most control systems and software

are now based on an “open architect” type of system,

if it is not already standard, it is usually just a matter

of what you want, how much it is worth to you, and

how quickly or easily it can be implemented.

Index Drives

A new standard has been made: nearly 90% of machines

being built today are constructed with motor driven index

systems. Both shuttles and rotaries are being built with

index speeds measured from station to station in approximately

3 to 6 seconds, depending on overall machine size or

the application’s requirements. In the past, traditional

machines were designed using pneumatic systems ranging

anywhere from 8 to 14

seconds. These time

savings come right out

of the overall cycle

time. Not only does

this feature allow for

faster cycles, but

allows for better forming

of thinner gauge

materials and materials

that traditionally

cool too quickly. In addition, the costly expense of maintaining

older pneumatic systems is virtually eliminated. As

motor driven systems are smoother and much more accurate,

there is less wear and tear and less machine vibration.

systems. Both shuttles and rotaries are being built with

index speeds measured from station to station in approximately

3 to 6 seconds, depending on overall machine size or

the application’s requirements. In the past, traditional

machines were designed using pneumatic systems ranging

anywhere from 8 to 14

seconds. These time

savings come right out

of the overall cycle

time. Not only does

this feature allow for

faster cycles, but

allows for better forming

of thinner gauge

materials and materials

that traditionally

cool too quickly. In addition, the costly expense of maintaining

older pneumatic systems is virtually eliminated. As

motor driven systems are smoother and much more accurate,

there is less wear and tear and less machine vibration.

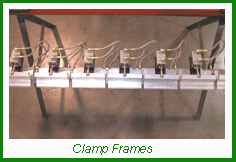

Clamp Frame

Clampframes have been evolving at record speeds over

the past few years, making more products capable of

being produced

in the thermoforming

process

whereas in the

past they may

not have been.

With over 20

application-specific

systems

that do everything

from being infinitely adjustable to tilting, bending,

slip sheeting and articulating, clampframes are helping to

reduce material thickness, reduce sheet sizes, induce sag,

reduce sag and even conform to the molds shape prior to

forming.

One of the most popular items available for every application

is adjustable clampframes. They have been one of

the single hottest items to hit the thermoforming machinery

market. You no longer need to store and replace different

lengths of clampframe for the diverse sheet sizes

required to run different jobs. Adjustable clampframes

offer the ability to vary the length of the clamp frames

without having to add or remove clamp frame sections

from the machine, and with no tools required! Not only

can you change these frames in under 5 minutes, but you

can also document the position of these clamp frames and

easily return them to the exact position the next time the

product is run. Adjustable clampframes are continually

proving to save anywhere from 1-3 hours of downtime

(per mold changeover), depending on the type of machinery

or how many stations your equipment has.

the single hottest items to hit the thermoforming machinery

market. You no longer need to store and replace different

lengths of clampframe for the diverse sheet sizes

required to run different jobs. Adjustable clampframes

offer the ability to vary the length of the clamp frames

without having to add or remove clamp frame sections

from the machine, and with no tools required! Not only

can you change these frames in under 5 minutes, but you

can also document the position of these clamp frames and

easily return them to the exact position the next time the

product is run. Adjustable clampframes are continually

proving to save anywhere from 1-3 hours of downtime

(per mold changeover), depending on the type of machinery

or how many stations your equipment has.

In addition to speeding up your clampframe changeover

time, all of today’s clampframe designs are made to

keep sheet sizes to a minimum. Some of the older or poorly

designed clampframe systems require up to 2” of material

to be clamped in your frames. The standard of clamping

on 1/2” or less has been implemented for over a

decade but has now become standard!

Moving Ovens

As oven technology expands, more thermoforming

machines are being equipped with lower tracking oven systems.

As sheets are being heated, most common materials

begin to sag. As sag increases, the lower oven will keep an

equal distance away from the sheet until it has reached

optimal temperature, and will then index into the form station

to complete the process. This feature not only allows

for more precise control, but is a great means of saving

energy. For excessive sag materials, or large sheets that

sag due to size and weight, lower ovens no longer need to

be set at 20” or more away from the sheet-line when heating.

Traditional ovens are lowered below the maximum sag, which then requires the lower oven settings to be programmed

at extreme temperatures just to penetrate heat

into the sheet. Ovens can now be set much closer to the

sheet-line as they will move downward with the sag. When

this is implemented, typically oven settings can be at much

lower temperatures and still within the same heating time

- if not faster. This makes for much better use of the heat

and uses much less energy to produce the product.

Another moving oven feature that is gaining popularity

is referred to as an oven-over or shuttling oven.

Traditional U.S. style machines have fixed oven stations,

but more thermoformers are finding use and applications

for an oven that traverses into the form station. This feature

allows an upper oven half to actually shuttle out of

the oven station and into the form station. For very thin

materials or materials that cool too quickly, an oven-over

feature can follow the sheet into the form station to help

retain heat. Clients in point-of-purchase have found that

not moving the sheet but instead moving the oven half (or

halves) to the sheet allows them to hold tighter registration

when forming materials with screen printed graphics.

In addition to helping the forming process, it can also aid

in speeding up the pre-heating of molds rather than just

waiting on water or oil temperatures or using sheets of

plastic to heat the mold to optimal temperature.

Platens

The industry has raised the standards in new machine

form stations to accommodate some of the more engineered

thermoplastics being developed and the new

applications being introduced to our market. As the

motor driven platen has replaced nearly all pneumatic

platen drive systems, it easily has become today’s standard.

The motorized systems have proven to be more

accurate, more consistent, more controllable, faster and

unbelievably highly programmable. Not only has the bar

been raised to all motor driven platens, but to multiple

ways of driving them. Although the motor driven platen

system was traditionally based on a chain drive, numerous

different drive systems have been created to eliminate

chain slack and maintenance as well as to create more

precise forming stations. From Direct Drive Twin

Synchronized Motors to a single motor with multiple gear

box direct drives, a larger variety of application-specific

designs are available and have become standard.

Not only have drives been upgraded, but platen

strengths and weights have greatly increased to accommodate

some of the more challenging applications that

use higher pressures, twin sheet forming and even match

mold compression forming.

Platen speeds have also increased, by nearly 40%! The

need to travel rapidly into the heated sheet has become

more critical in today’s marketplace.

Even on the most basic machines, all platen positioning

and motor speeds are now controlled through the

machine’s control system. Gone are the time consuming

days of manually adjusting collars or limit switches. Today,

motor driven platens are equipped with encoders for fast

setups, repeatable speeds and precise positioning. The

encoders are interfaced into the control system with real

time graphic emulation of platen movement displayed on

screen. The platen settings are stored in the controller with

each job number for future recall. Encoder driven platens

no longer require homing or zeroing and the machine may

be turned off without losing platen home position.

Larger Machine Technology

Some of the most recent developments in large machine

construction have opened new doors for our industry. It is

no longer being considered

a risk to purchase

and implement

larger machine

sizes. Previous

large machine technology

was minimal

due to the limited

demand, and machine

manufacturers

did not have enough

experience to costeffectively

design

and build them. With today’s technology advancements and

increasing market demand this has now changed.

no longer being considered

a risk to purchase

and implement

larger machine

sizes. Previous

large machine technology

was minimal

due to the limited

demand, and machine

manufacturers

did not have enough

experience to costeffectively

design

and build them. With today’s technology advancements and

increasing market demand this has now changed.

Over the past several years more machines are being

built to accommodate some of the largest molds or largest

thermoformed products ever manufactured in high volume quantities. Today, more innovative companies are discovering

the true advantage of larger machines and developing

parts that are larger than ever before. In addition to an

increasing demand for large parts, these large machines are

also being utilized to run multiple molds at once in order to

reduce costs and increase parts per hour. For example, one

of the higher volume thermoformed parts are pallets.

Traditional pallet machines ran 2 to 4 up, but as competition

grows companies are going larger with machines capable

of running 6 to 8 up. Some of the largest new thermoforming

machines manufactured over the past two years

are 16’ x 8’, 19’ x 10’, 14’ x 8’, and 21’ x 9’. Some of these

are straight vacuum formers, some pressure formers, and

one is even perhaps the largest twin sheet thermoforming

machine in the world with a 21’ x 8’ forming area.

Automation

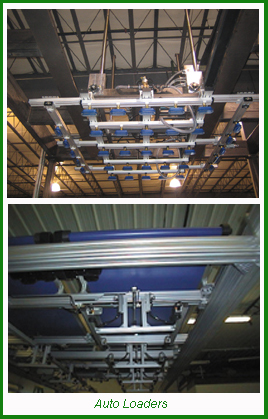

Automation has increased its role in our process and is

being implemented more often than ever before. The

increased demand for automation helps to reduce costs as

many systems have now become standard sub-assemblies

rather than “one-of” projects. With large sheets or hard to

handle sheets, automated systems are becoming necessary

to avoid the need for multiple loading and unloading

personnel. In competitive markets where machines are

running 6 to 8 up with fast cycle times, automation is also

necessary to help load the 6 to 8 sheets while simultaneously

unloading 6 to 8 finished parts.

increased demand for automation helps to reduce costs as

many systems have now become standard sub-assemblies

rather than “one-of” projects. With large sheets or hard to

handle sheets, automated systems are becoming necessary

to avoid the need for multiple loading and unloading

personnel. In competitive markets where machines are

running 6 to 8 up with fast cycle times, automation is also

necessary to help load the 6 to 8 sheets while simultaneously

unloading 6 to 8 finished parts.

Automation has also come into play due to the

increased demand for part inserts. These can be various

metals, foam or even

wood parts that are

inserted during the

thermoforming

process and become

part of the actual

finished product.

Typically these

inserts are placed

into a mold cavity in

the form station

before the sheet is

formed, or they are

placed between two

sheets in the twin

sheet forming

process. Little time

is given for these

inserts to be properly

placed manually,

and safety is always a concern when personnel are

required to enter a machine in production mode.

Automated robots and automated pick and place systems

are being incorporated to assist in this aspect to help

reduce labor costs, increase personnel safety, gain

repeatability and keep scrap rates to a minimum.

Summary

Today’s new thermoforming machines are available with

over 150 options, almost four times that of 5 years ago.

Some are application-specific, and some are quickly

becoming new industry standards. The large array of

options and capabilities now being offered certainly allows

thermoformers to focus in on features that will help them

create a unique machine specification, allowing them to

hold stronger competitive advantages. Almost every

machine being built today is specified around the thermoformers

core market, or specific applications and production

requirements. These new innovations are changing

the old mind set of buying all-purpose machines. The general

purpose machine has lost its place in the thermoforming

market. As competition grows, thermoformers

are becoming smarter and equipping themselves with new

technology in order to create their competitive edges.

Companies who are serious and are here to stay need

to invest in new technology. More than half of our industry

is operating machines that are over 20 years old, so

we do not need to ask why their profit margins continue

to decrease. The time has come to get rid of your old thermoforming

machine and buy new. Replace that typewriter

of yours, and see for yourself how much more efficient and

how much more profitable a computer really is!

Written by Michael P. Alongi, Sales Director for MAAC

Machinery Corp., manufacturers of a wide range of cutsheet

thermoforming machinery.

For more information, contact

MAAC Machinery Corp., 590 Tower Blvd., Carol Stream, IL

60188, 630-665-1700, Fax: 630-665-7799, E-mail: sales@

maacmachinery.com, Web: www.maacmachinery.com.

|