|

THERMOFORMING: Top Ten Tips to Becoming More Efficient in Thermoforming

As today’s heavy gauge thermoforming market is

growing and becoming more competitive, companies

are looking for better ways to gain efficiencies.

A large portion of a company’s success comes from the

efficiencies they have or the efficiencies they create.

Through years of working with thermoformers, we often

work with companies that we can help gain major efficiencies.

Although engineering firms, suppliers and consultants

are not necessarily needed to implement

improvements, they all have the continual opportunity to

work with thousands of thermoformers and thousands of

different applications. From a general viewpoint, here are

10 tips to be more efficient, or areas where improvements

can be implemented. With the proper knowledge, companies

should assess their strengths and weaknesses and

begin preparing for future plans to address their major

inefficiencies.

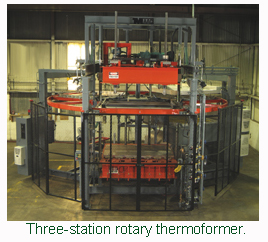

1. Outdated

Equipment

As thermoforming

is not a new

process, thermoforming

equipment

has been around for

over 50 years. This

does not mean you

should keep your

machines for 50 years! Begin putting together long-term

plans to replace or upgrade them. Old, inefficient

machines are the single largest item that restricts manufacturers’

ability to run at their most efficient. Older

machines also tend to have limited capabilities and offer

no real competitive advantage. The term, “it paid for it self

already” does not make you efficient.

has been around for

over 50 years. This

does not mean you

should keep your

machines for 50 years! Begin putting together long-term

plans to replace or upgrade them. Old, inefficient

machines are the single largest item that restricts manufacturers’

ability to run at their most efficient. Older

machines also tend to have limited capabilities and offer

no real competitive advantage. The term, “it paid for it self

already” does not make you efficient.

A large portion of a company’s success comes from the

equipment they utilize. If you never investigate the latest

technology or do not have plans to invest in the latest technology,

this may be the single largest mistake you can

make. With all of the technological advancements available

in today’s new machinery, older machines cannot be compared

and certainly cannot compete in terms of performance,

cycle time, material distribution, energy use, repeatability,

change-over time, flexibility and even maintenance.

2. Tooling/Molds

One of the most limiting factors leading to running efficient

stems from poor mold designs and, even worse,

the type of material chosen to construct the mold.

Regardless of your machinery being new or old, a

bad mold will dictate your ability to be efficient.

Regardless of your machinery being new or old, a

bad mold will dictate your ability to be efficient.

Although the volume of products produced or the

design of the finished product may dictate what can

be used, too many formers start with looking for the

least expensive way to get a mold and start producing

products the fastest. A badly designed mold or

molds that are not water cooled aluminum will allow

competitors to redesign and improve cycle times

lowering overall manufacturing costs. Patching up

poorly designed molds may help, but will only allow

you to run your product at what the mold design

allows for. Too often formers are running high volume

jobs, in some cases several shifts, with multiple

non-water cooled molds; when one good aluminum

water cooled mold can be utilized to produce parts

up to three times faster. Production cycle times

should never be based upon how long it takes your

mold to cool off between shots unless the volume is

very low or you are prototyping. 3.

Cycle Times

As there are many ways to improve cycle times,

we far too often see products running too slow.

Thermoformers need to take the time to improve, determine

the bottle neck and implement a way to correct it. If

the problem is heating times, make plans to improve your

ovens or spend more time setting them up and tweaking

them. If the issue is forming and cooling times, look to

replace tooling with better molds or investigate alternative

cooling options. If secondary operations are much

more time consuming, look for more options and capabilities

to speed up the process or be open to jobbing the

work out to someone who may be more efficient in that

portion of the process.

4. Sheet Size

Use smaller sheets: far too many thermoformers are

using too much material. Look for ways to reduce your

material costs and implement a new standard. Look at

your clamp frames; are you clamping more than 1/2”? Do

not try to get 50 years out of a piece of clamp frame, you

will easily spend the money in material costs in the long

run due to sheets pulling out, oversizing the sheet and

increased scrap rates. Replace damaged or bent frames:

utilize frames that require less than 1 inch in the clamp.

Work on utilizing thinner gauge sheets too. This can be

achieved with more oven control, better oven designs and

the use of different forming techniques. Material gauges

can be greatly reduced and still meet your finished parts’

minimum thickness requirements.

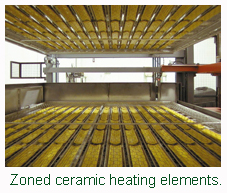

5. Ovens and Oven Controls

Older ovens need attention. Maintain them to get the

most out of your machines. Costly retrofits are one option,

but typically only help in one area of your machine. For

30% to 40% of a new machine cost, oven retrofits are typically

seen as a short term solution to gain efficiencies.

Get more oven control, or at least some control. Machines

with no “Zones” should not be used unless you have no competition

and are a non-profit organization. The additional

utility costs for operating the entire oven when smaller

sheets are used is not efficient and costs too much with

today’s utility prices. You need oven zones to shut off areas

that are not heating the sheet, zones also allow you to gain

more control over the process to decrease heating times and

even decrease starting sheet gauges. Having zones in your

oven also eliminates the need to physically screen an oven or

block heat transferring into the sheet. Physical screening is

both time consuming and an inefficient use of energy. 6.

Over Heating the Sheet

Stop overheating the sheet. Many thermoformers are

overheating the sheet as they do not know what temperature

the sheet is. The days of visually detecting sag or

touching the sheet to measure temperature are gone.

Photo eyes and infrared pyrometers are used for detecting

sheet sag or sheet temperature. Some of these devices

can be purchased for less than $100. If you overheat the

sheet, forming and cooling times are extended, making

cycle times much longer than necessary. Not to mention

the additional wear and tear on your machine, your mold,

the extra costs you pay for labor and the added utility cost

used to overheat the material.

the sheet is. The days of visually detecting sag or

touching the sheet to measure temperature are gone.

Photo eyes and infrared pyrometers are used for detecting

sheet sag or sheet temperature. Some of these devices

can be purchased for less than $100. If you overheat the

sheet, forming and cooling times are extended, making

cycle times much longer than necessary. Not to mention

the additional wear and tear on your machine, your mold,

the extra costs you pay for labor and the added utility cost

used to overheat the material.

7. PLC’s and Quick Set Ups

Updating machines from manual timers to PLC controls

is a step forward but PLC’s programmed by nonindustry

professionals will most likely limit the machines capabilities

and only allow a slight increase in efficiencies. Again,

this should be looked at as a short term fix.

Thermoforming machine manufacturers who build these

controllers can at least guarantee flexibility, full functioning

and support.

Companies must fully investigate the control systems

and all features that will benefit their operation. The latest

controllers allow you to memorize all functions of the

machine for each job you run. This means all the time it

takes to manually program a machine is reduced to the

touch of a button the second time the machine is set up.

The possibility of damaging the machine or producing

scrap is greatly reduced, and the ease of continually

tweaking specific applications is simplified.

8. Cooling

The thermoforming process may begin with heating the

sheet, but acquiring the fastest cycle times is not solely

based on how fast you can heat the sheet. In order to

establish faster cycles with materials that have longer

cooling characteristics (than heating characteristics), you

must accommodate the cooling process.

Whether you need additional cooling fans, a directional

blower, spray mist or even air conditioned

cooling, there are numerous

ways to incorporate these. Precise

location and positioning of these cooling

systems will also lead to faster

cooling times. Automated in-machine

post cooling may be needed for heavy

gauge products in order to run the

machine based on heating times

rather than cooling times. Depending

on part specifications and tolerances,

post cooling can be the key to gaining

more parts per hour.

9. Trimming

Too often thermoforming machine

cycle times are extended to match the

trimming process time. Again, companies

who investigate in the newest

methods of trimming and trimming

speeds may find ways to speed up the

parts trimmed per hour. With newer

equipment with faster speeds, some

applications can see a 300% increase

in parts per hour. A little more time

spent on tightening up the programming

can now result in parts per hour

increases as high as 500%.

10. Vacuum

Insufficient volume, recovery time

and insufficient pressure are often the

cause for deficient processing causing part variation and

increasing scrap rates. Determine the amount of work to

be done in cubic feet or cubic inches. Items needed to calculate

amount of work are: process (possible predraw box),

sag, tool and tool cavity. Large tool cavities are back-filled

with polyethylene balls to reduce the amount of cubic feet

needed. Determining the flow in cubic feet per minute will

result in the amount of time at a specific pressure (hg) to

evacuate the needed cubic feet of work. Items needed to

calculate are: tool port size, distance from tool port to vacuum

valve, vacuum valve flow in cfm, starting pressure and

tank volume. By adding pump starting pressure and cfm

capacity, the recovery time may be calculated.

Although this is all easier said than done, companies

who are in it for the long run will continually look for ways

to improve and gain efficiencies. Whether you develop

short or long term plans, or implement temporary fixes to

help gain efficiencies, you must start preparing to stay

ahead of the market.

Written by Michael P. Alongi, Sales Director for MAAC

Machinery Corp., manufacturers of a wide range of cutsheet

thermoforming machinery.

For more information, contact MAAC Machinery

Corp., 590 Tower Blvd., Carol Stream, IL 60188, 630-665-1700, Fax: 630-665-7799, E-mail: sales@maacmachinery.com, Web: www.maacmachinery.com

|