|

Laser Cutting Thermoplastics

Lasers have been utilized for pointing,

engraving, welding and cutting

applications for decades. The

process for Laser Light generation, originally

known as “Maser” was developed in

1953 to amplify microwave signals detected

in distant stars.

The first evidence of

Laser Light generation was in 1960 by

Theodore Maiman who successfully oscillated

a ruby with solid state control. Over

the next few years, development was rapid with the introduction

of He Ne gas (Helium Neon) laser. In 1964 Kumar

Patel invented the CO2(Carbon Dioxide) laser while

another team, J.E. Geusic, H.M. Markos and L.G. Van

Uiteit invented the Nd:YAG, Neodymium:Yttrium

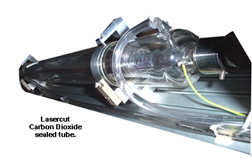

Aluminum Garnet Laser. (Figure 1)

The first evidence of

Laser Light generation was in 1960 by

Theodore Maiman who successfully oscillated

a ruby with solid state control. Over

the next few years, development was rapid with the introduction

of He Ne gas (Helium Neon) laser. In 1964 Kumar

Patel invented the CO2(Carbon Dioxide) laser while

another team, J.E. Geusic, H.M. Markos and L.G. Van

Uiteit invented the Nd:YAG, Neodymium:Yttrium

Aluminum Garnet Laser. (Figure 1)

CO2 and N2 (Nitrogen) are natural found

gases that exist in our atmosphere: when

combined with He (Helium) they form the

Lasing gas in CO2 lasers. The CO2 molecule

is called the active medium and is the

source for the laser emission. Solid state

lasers utilize atoms combined with crystals

such as ruby or YAG. When doped with a

medium Cr (Chromium Ions) or Nd, they

constitute the active lasing medium.

The gas laser resonator consists of a glass vacuum tube

that has a rear mirror (Figure 1) and an output coupler at the

other end; the medium is placed inside the tube. In the

case of CO2 lasers, the medium (He, N2, CO2) is sealed

within the glass tube and has a limited life span, once discharged

has to be replaced or recharged. With unsealed

CO2 lasers, gas is pumped into the vacuum tube from gas

bottles. The bottles of gas are readily available and can be

purchased ready mixed or separate per the laser needs.

There are also gas mix stations available that will mix the

gas into the appropriate proportions. A typical mix would

be 82% He, 13.5% N2, 4.5% CO2.

The wave length of laser light produced between

Nd:YAG and CO2 is used for specific material types and

applications. CO2 (typical 10.6 m wave length) is mainly

used for cutting applications in metal, plastic, wood and

with certain controls is used to engrave non-metallic materials

at high speed. CO2 Lasers have working powers up to

10,000 watts and beyond.

Lasercutting Table Types

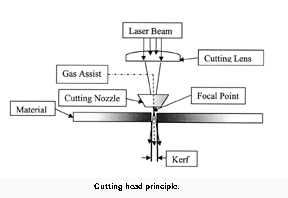

Cutting Head

The cutting head consists of a

nozzle, lens, gas assist and may

include Z axis control. The Lens is

an important feature associated

with cutting.

The characteristics

are usually meniscus shape and

made of Zn Se (Zinc Selenium)

with a focal length (F.L.) of 5”. As

the beam passes through the lens

a hot spot is focused, (focal point,

F. P.,in this case at 5”) from the

lens and is assisted with clean dry

air (or nitrogen for its cooling non oxidant properties) to carry the intensity through the cutting nozzle orifice

vaporizing the material at the point of contact. A typical

width of cut (known as Kerf Width) would be around

0.013”. The position of the F.P. is important with relationship

to the material thickness and type. A normal start

point would be to set the F.P. to just sit on top of the material

surface. This is where a “Z” axis control is very desirable.

This is a motorized axis that allows the cutting head

to move up or down with control from a potentiometer,

software or a surface follower. It also allows the cutting

head to fully retract on job completion for ease of loading

and unloading. “Z” Axis control is important to ensure

The characteristics

are usually meniscus shape and

made of Zn Se (Zinc Selenium)

with a focal length (F.L.) of 5”. As

the beam passes through the lens

a hot spot is focused, (focal point,

F. P.,in this case at 5”) from the

lens and is assisted with clean dry

air (or nitrogen for its cooling non oxidant properties) to carry the intensity through the cutting nozzle orifice

vaporizing the material at the point of contact. A typical

width of cut (known as Kerf Width) would be around

0.013”. The position of the F.P. is important with relationship

to the material thickness and type. A normal start

point would be to set the F.P. to just sit on top of the material

surface. This is where a “Z” axis control is very desirable.

This is a motorized axis that allows the cutting head

to move up or down with control from a potentiometer,

software or a surface follower. It also allows the cutting

head to fully retract on job completion for ease of loading

and unloading. “Z” Axis control is important to ensure

that the cutting nozzle and lens are adjustable and allow

for easy beam alignment. A typical cutting nozzle would

have a 0.060 orifice. The focused laser beam, when

passed through the cutting lens has to be central and

perpendicular to the lens, and in turn central to the nozzle

orifice. Any deviation from this would drastically affect

the quality of cut. If the beam clips the nozzle orifice, by

even 0.001”, a poor quality material surface cut would be

produced that would also be out of perpendicularity.

that the cutting nozzle and lens are adjustable and allow

for easy beam alignment. A typical cutting nozzle would

have a 0.060 orifice. The focused laser beam, when

passed through the cutting lens has to be central and

perpendicular to the lens, and in turn central to the nozzle

orifice. Any deviation from this would drastically affect

the quality of cut. If the beam clips the nozzle orifice, by

even 0.001”, a poor quality material surface cut would be

produced that would also be out of perpendicularity.

Fixed Beam

The laser power source remains static and is mounted

onto a solid support stand.

The beam delivery and nozzle

are held in a fixed position over the work area. The Laser

table moves in X and Y directions to replicate the programmed

design.

The laser beam has a fixed beam length ensuring uniform

quality cuts across the working area. This process is

excellent for

manufacturing

die

boards and provides excellent

kerf.

However, the

large foot

print takes

up floor

space. In some instances floor space

may be at a

premium. For

instance, a

system having a work area of 50”x 60” would require in

excess 130” x

150”, more

than double the

work area.

The beam delivery and nozzle

are held in a fixed position over the work area. The Laser

table moves in X and Y directions to replicate the programmed

design.

The laser beam has a fixed beam length ensuring uniform

quality cuts across the working area. This process is

excellent for

manufacturing

die

boards and provides excellent

kerf.

However, the

large foot

print takes

up floor

space. In some instances floor space

may be at a

premium. For

instance, a

system having a work area of 50”x 60” would require in

excess 130” x

150”, more

than double the

work area.

HyBrid Laser System

The Hybrid is similar to the

Fixed Beam but has one moving axis and one flying optic.

With flying optic, the laser source is usually positioned to

the side or rear of the table. The beam is guided from the

power source through a series of elbows, housing mirrors

and steered to the cutting lens position. The farther the

cutting lens distance from the power source, the greater

the beam diameter. Divergence relates to the laser beam

increasing in diameter as the distance increases between

Laser source and cutting lens. With a flying optic this

becomes critical as one mirror (axis) is continually moving

back and forth in order to cut the part. The diameter of

the beam continually increases and decreases as it passes through the cutting lens which in turn affects the quality

of the Kerf

width. Also any

slight misalignment

of the

beam as it passes

through the

90° elbows, or

mechanical

looseness in the

system will

cause the beam

to change position

from the

center of the

cutting lens and

in turn move the

F. P. position, again degrading the quality of cut. A normal

control employed with a flying optic is to move the F.P.

position with the Z axis for compensation. The amount of

displacement would depend on the divergence and laser

power. The flying optic portion of the system should work

under pressurized conditions to prevent dust particles settling

on to the 90° mirrors and cutting lens.

The Hybrid has a small foot print as the work table only

moves in one axis. However,

if the beam requires regular alignment to maintain a

consistent Kerf, it is usually difficult for the novice.

With flying optic, the laser source is usually positioned to

the side or rear of the table. The beam is guided from the

power source through a series of elbows, housing mirrors

and steered to the cutting lens position. The farther the

cutting lens distance from the power source, the greater

the beam diameter. Divergence relates to the laser beam

increasing in diameter as the distance increases between

Laser source and cutting lens. With a flying optic this

becomes critical as one mirror (axis) is continually moving

back and forth in order to cut the part. The diameter of

the beam continually increases and decreases as it passes through the cutting lens which in turn affects the quality

of the Kerf

width. Also any

slight misalignment

of the

beam as it passes

through the

90° elbows, or

mechanical

looseness in the

system will

cause the beam

to change position

from the

center of the

cutting lens and

in turn move the

F. P. position, again degrading the quality of cut. A normal

control employed with a flying optic is to move the F.P.

position with the Z axis for compensation. The amount of

displacement would depend on the divergence and laser

power. The flying optic portion of the system should work

under pressurized conditions to prevent dust particles settling

on to the 90° mirrors and cutting lens.

The Hybrid has a small foot print as the work table only

moves in one axis. However,

if the beam requires regular alignment to maintain a

consistent Kerf, it is usually difficult for the novice.

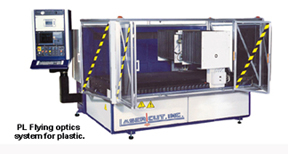

Flying Optics

Flying Optics has the same criteria as the Hybrid, but

both X and Y have optics that move and the cutting area is

static.

It has a very small foot print, almost equal to the work

area, but is not suitable for Die making, However it is

excellent for plastics and metal cutting.

Flying Optics has the same criteria as the Hybrid, but

both X and Y have optics that move and the cutting area is

static.

It has a very small foot print, almost equal to the work

area, but is not suitable for Die making, However it is

excellent for plastics and metal cutting.

Articulated Arm

This is the ultimate

setup for

quality control

issues because

the beam length

is always consistent.

The bed is

static and renders

a footprint

equal to the flying

optics system.

As the beam exits the laser power source it is guided into a

closed pressurized hollow arm that has flexible joints. The

arm is allowed to swivel at each joint; each joint has a

beam bender mirror that reflects the laser beam from

joint to joint reaching the cutting lens with a constant

beam diameter.

This method of

control is ideal

for all applications

including

plastic, die

board and

metal cutting.

The bed is

static and renders

a footprint

equal to the flying

optics system.

As the beam exits the laser power source it is guided into a

closed pressurized hollow arm that has flexible joints. The

arm is allowed to swivel at each joint; each joint has a

beam bender mirror that reflects the laser beam from

joint to joint reaching the cutting lens with a constant

beam diameter.

This method of

control is ideal

for all applications

including

plastic, die

board and

metal cutting.

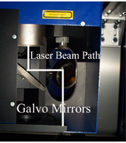

Galvo

Controlled

Marking

And

Cutting

Systems

The Galvanometer is an instrument for measuring a

small electrical current or a function of the current by

deflection of a moving coil.

The deflection is a mechanical

rotation derived from forces resulting from the current.

This rapid deflection is used to direct the laser beam at

high speed

across a material

surface to

engrave and or

cut material.

The Galvo head

consists of 2

mirrors that are

attached to

coils.

The deflection is a mechanical

rotation derived from forces resulting from the current.

This rapid deflection is used to direct the laser beam at

high speed

across a material

surface to

engrave and or

cut material.

The Galvo head

consists of 2

mirrors that are

attached to

coils.

An electrical

current

excites the coils

and causes

them to orient

in the magnetic

field generated

by high power magnets. This rotation is controlled from

the programmed image via software. The laser beam

passes through a series of lenses, (dynamic focusing system)

is bounced between mirrors by the Galvanometric

action and then projected down onto the work surface. A

typical engraving speed of 7 ft per second is attainable

with working areas of 64” x 64”. This principle is used with

CO2 and

Nd:YAG laser

sources. CO2 is

primarily considered

for

engraving/cutting

non-metal

material.

An electrical

current

excites the coils

and causes

them to orient

in the magnetic

field generated

by high power magnets. This rotation is controlled from

the programmed image via software. The laser beam

passes through a series of lenses, (dynamic focusing system)

is bounced between mirrors by the Galvanometric

action and then projected down onto the work surface. A

typical engraving speed of 7 ft per second is attainable

with working areas of 64” x 64”. This principle is used with

CO2 and

Nd:YAG laser

sources. CO2 is

primarily considered

for

engraving/cutting

non-metal

material.

Cutting

Speeds

Material thickness and cutting speed has a direct relationship

to power. Increased power allows for cutting

thicker materials and for faster speeds. A typical cutting

speed chart is shown for Acrylic cutting (Figure 8).

It

should be noted this relates to 250 and 500 watt power

sources having a polished finish and non-polished finish

speeds. Powers can be well in excess of 500 watts if

required. For 1/8” polished finish at 250 watt, and 1/8”

polished finish at 500 watt, the cutting speed is the same.

This demonstrates that the process with polished finish is

speed-critical. For “finished polish” the speed is always

slower than “non-polished” finish. However, with correct

power and

speed the

acrylic surface

temperature

melts to attain a

highly polished

edge. Critical to

this process is

the need for a

quality beam

mode and a well

tuned laser. This

ensures that the

edges remain

cool enough and

not to fuse back

together. This helps in product removal and, in the case of

adhered polished parts, reduces the risk of crazing. The

advantages of using 500 watt and up is increased cutting

speed and ability to cut and polish 1” thick acrylic.

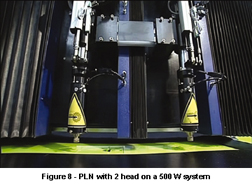

Another advantage is to have the ability to add a second

head. In the example for 1/8” acrylic, double the production

throughput by splitting 500 watts into two 250 watts

per head. (Figure 9) Gas consumption and running cost

remains unchanged with double the throughput. This is a

low cost solution for increased productivity.

It

should be noted this relates to 250 and 500 watt power

sources having a polished finish and non-polished finish

speeds. Powers can be well in excess of 500 watts if

required. For 1/8” polished finish at 250 watt, and 1/8”

polished finish at 500 watt, the cutting speed is the same.

This demonstrates that the process with polished finish is

speed-critical. For “finished polish” the speed is always

slower than “non-polished” finish. However, with correct

power and

speed the

acrylic surface

temperature

melts to attain a

highly polished

edge. Critical to

this process is

the need for a

quality beam

mode and a well

tuned laser. This

ensures that the

edges remain

cool enough and

not to fuse back

together. This helps in product removal and, in the case of

adhered polished parts, reduces the risk of crazing. The

advantages of using 500 watt and up is increased cutting

speed and ability to cut and polish 1” thick acrylic.

Another advantage is to have the ability to add a second

head. In the example for 1/8” acrylic, double the production

throughput by splitting 500 watts into two 250 watts

per head. (Figure 9) Gas consumption and running cost

remains unchanged with double the throughput. This is a

low cost solution for increased productivity.

To Laser Cut Or Not Laser Cut

Lasers offer many advantages when compared to conventional

cutting techniques; a quality edge finish is

achievable in a single pass, limited waste due to a thin kerf and increased productivity due to eliminated steps in fabrication.

Most materials can be laser cut, but it is always recommended

to obtain Material Safety Data Sheets (MSDS) to

ensure that the material for process does not contain

harmful chemicals that may be emitted when laser

processed (as any other thermal process). The general

guide is that PVC-type materials should not be laser

processed because of the harmful emission of Hydrochloric

Acid, the poor cut quality, having darkened to black

edges, possible damage to the machine and optics and it

is environmentally unsafe. Types of material that do not

cut well are thermosets and high temperature materials.

Epoxies, Phenolic resins and most natural rubber products

are included in this category.

Materials that cut well (thermoplastics) with laser processing

are: Acrylics, Polystyrene, Polyethylene, Polyamide

(nylon) and Polypropylene. With correct power range,

speed and good quality mode (profile of the beam), materials

can be processed in excess of 1” thick with clean polished

edges.

Cutting Speeds for Acrylic Type Material

| Nominal Laser Power | | Nominal Laser Power |

| 250W | | 250W |

| Polished Finish | | Non-Polished Finish |

|

| Thickness |

Cutting Speed |

| Cutting Speed |

|

| 1/8 |

80”/min |

| 160”/min |

|

| 3/16 |

40”/min |

| 120”/min |

|

| 3/8 |

20”/min |

| 60”/min |

|

| 9/16 |

15”/min |

| 31”/min |

|

| 3/4 |

120”/min |

| 24”/min |

|

| Nominal Laser Power | | Nominal Laser Power |

|

| 250W | | 250W |

|

| Polished Finish | | Non-Polished Finish |

|

| Thickness |

Cutting Speed |

| Cutting Speed |

|

| 1/8 |

80”/min |

| 315”/min |

|

| 3/16 |

60”/min |

| 157”/min |

|

| 3/8 |

40”/min |

| 118”/min |

|

| 9/16 |

31”/min |

| 80”/min |

|

| 3/4 |

24”/min |

| 47”/min |

|

| 1” |

16”/min |

| 31”/min |

Figure 9

Written by Terry Grainger, Lasercut, Inc., manufacturers

of systems for laser cutting and high speed galvanometric

marking for the plastics industry.

For more information, contact Lasercut, Inc., 69 North Branford Road,

Branford, CT 06405, 203-488-0031, Fax: 203-483-0463, E-mail: lasercut@lasercutinc.com, Web: www.lasercutinc.com.

| Return Home | Back To Top |

|