|

Painting Acrylic Sheet

The superior clarity and long-term durability of

acrylic sheet allow for easy painting and printing of

fabricated signs, displays and other decorative

items. However, simply choosing to use the material is not

enough to guarantee success. With

that in mind, the following guidelines

and the correct supplies will help you

produce high-quality acrylic sheet

products.

Paint

A variety of paints specifically

designed for acrylics are commercially

available. Most are supplied as

concentrates and require thinning to

obtain the correct viscosity.

As a rule, use mild thinner consisting of an alcohol

blend, rather than one containing aromatic hydrocarbons,

such as benzene and toluene. Always follow the paint suppliers’

recommendations about the

amount and type of thinner.

As a rule, use mild thinner consisting of an alcohol

blend, rather than one containing aromatic hydrocarbons,

such as benzene and toluene. Always follow the paint suppliers’

recommendations about the

amount and type of thinner.

Acrylic sheet’s extraordinary transparency

allows for back-painting (i.e.

applying paint to the side of the material

not exposed to weather). The

unpainted outer surface of the sheet

provides weather protection for the

paint. If you must paint the outer surface,

apply a suitable protective coating

over the paint.

Spraying Systems

Use any efficient, atomizing spray

gun system that uniformly distributes

paint. Consult your suppliers

regarding the equipment you need

for a particular application.

To obtain enough atomizing air,

the available line pressure should be

in the range of 414 to 621 kilopascals

(60 to 90 psig). Use a 7.6-m

(25-ft) long, minimum 8-mm (0.3-

in.) diameter hose to avoid pressure

drops in the line.

The air compressor should be

large enough to provide the volume and pressure required

for all spray guns.

Water and oil in the atomizing air will

spot the paint and cause uneven distribution. To prevent

this problem, use water and oil traps in the line.

Metal screen strainers at the pressure tank and spray

gun will ensure equipment cleanliness, which is also crucial

to uniform paint dispersion. Clean these items and the

spray gun daily.

Install an adequately vented spray booth that is large

enough to house your biggest work piece. Use a light box

to judge paint uniformity on transparent plastics. Be sure

the light box conforms to building code regulations for a

spray painting area.

Fabrication Techniques

Fabricating acrylic sheet using incorrect

techniques prior to painting may cause

stress in the material. This can result in

crazing (i.e. numerous tiny cracks) after

painting. You can eliminate crazing by following

the manufacturers’ recommendations

for fabricating acrylic sheet.

Cleaning

Always clean acrylic sheet before painting.

This will remove dust and assure paint

adherence.

Use special care in cleaning, as acrylic

sheet is sensitive to solvents, such as aromatic hydrocarbons,

concentrated alcohols and ketones. Clean parts with

a solution of distilled water and 25 percent denatured

alcohol.

For stains such as those caused by oil or grease, use

stronger cleaning agents, like hexane, aliphatic naphtha or

kerosene. Make sure the sheet is fully dry before painting.

Static Neutralization

It is important to neutralize electric or static charges

that can accumulate on the sheet’s surface and attract

dust before painting. Dust on the sheet causes paint

agglomeration and uneven layers.

Since tearing the masking off the sheet will create a static

charge, all acrylic pieces should be treated with an ionizing

air gun, which safely and effectively neutralizes electric

charges. Wiping the sheet with a damp, lint-free cloth

or cleaning with a diluted alcohol-water solution is also

effective.

Avoid anti-static cleaners. They can leave a residue and

cause paint adhesion problems.

Maskants

Acrylic sheet’s paper masking is commonly used as a

protective layer while spray painting flat signs. However,

paint manufacturers also distribute liquid maskants, which

are often used to spray designs onto acrylic sheet.

Maskant is supplied as a thick liquid, consisting of

water-soluble latex resins in a solution. It is applied

through the use of air (or airless) atomizing spray equipment.

Being a water solution, it must be stored at above

0º C (32° F), to prevent freezing.

Clogging may occur, due to dried film mixed with the

solution. You can prevent this problem with a special nozzle—

available from paint equipment suppliers—that

reverses the flow and cleans out the buildup.

Spray the maskant on evenly to a wet film thickness of

250 to 300 microns (10 to 12 mils). It will dry to above

100 to 125 microns (4 to 5 mils).

Maskant Drying

Drying time is usually about two hours. However, it is

better to plan for overnight drying to assure complete

evaporation.

Using forced-air heating at 43° C (110° F) can accelerate

the drying process. Higher temperatures might dry the

surface and prevent evaporation of the water in the layers

beneath it.

To prevent dust accumulation on the plastic surface,

leave the dried maskant in place just prior to painting.

Score the design on the film, using an exacto knife, applying

just enough pressure to cut the film without scratching

the plastic beneath.

After painting, leave the film in place until the paint is

thoroughly dry. Otherwise, you will end up with smeared

paint and uneven edges.

Painting

Before painting, practice on a few test pieces of acrylic

sheet to ensure paint viscosity and air pressure are correct.

As a rule, use the lowest possible pressure to obtain

the correct results.

Too high a

delivery rate

will result in an

excess of paint

and cause

paint sag. It

can also cause

crazing of the

sheet, due to

too much solvent.

Too low a delivery rate, on the other hand, will result in dry

spray—i.e. a matte surface caused by too much dusting.

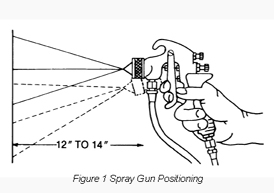

Hold the gun 300 to 350 mm (12 to 14 in.) from the

work piece; being too close or too far away will cause the

defects listed above (Figure 1).

Move the gun at an even pace and in a straight line. Its

movements should never start or stop when directly facing

the sheet surface.

Vary the direction of the spray, both horizontally and

vertically, to assure uniform coverage. Four or five passes

with several seconds between coats will provide sufficient

paint. Using a light box behind the acrylic sheet will help

you judge the uniformity and intensity of color.

Screenprinting

When used for high-volume production, screenprinting

is fast and economical. For beginners, it is best to purchase

a screen from a local screen supply house.

After set-up, apply paint with the squeegee in a uniform

and even motion in one direction. The paint will pass

through the open screen mesh, transferring the pattern

onto the acrylic.

The most important factors are the paint’s viscosity and

the size of the mesh openings. These will determine paint

flow through the screen and the paint’s appearance on the

acrylic.

It is difficult to generalize what these conditions should

be. Many different fabrics are used for screens and paint viscosity depends on the application methods and temperature.

Consult your paint manufacturer for advice

about thinning paint.

Paint Removal

If paint removal from the acrylic sheet’s surface is necessary,

it should be performed immediately. Use the paint manufacturer’s

recommended cleaner. Apply the paint remover

with a rag, then wipe off the paint using another clean rag.

Paint removers contain organic solvents. Therefore, to

reduce the chance of crazing, you should minimize the period

during which the remover is in contact with the acrylic sheet. Troubleshooting Guide

| Problem | Cause | Solution |

| Maskants | | |

|

| Weak and brittle maskant | Air bubbles in film | Dilute slightly |

|

| Film not thoroughly dry | Wait recommended drying time |

|

| Maskant film too thin | Increase thickness to 3-5 mils (10-12 mils wet). |

|

| Too much adhesion | Maskant film too thin | Increase thickness to 3-5 mils (10-12 mils wet). |

|

| Coating exposed to UV | Do not store faces outside. |

| Spray Paints | | |

|

| Poor adhesion | Incorrect paint | Use paints recommended for use with acrylic |

|

| Dirt or residue on sheet | Clean sheets thoroughly before painting |

|

| Blotches of paint | Static electricity | Neutralize charges with ionizing gun or wipe with damp cloth |

|

| Uneven paint application | Apply paint in more passes, using less paint per pass |

|

| Paint not applied uniformly | Use backlighting to check paint as it is being applied. |

| Screen Paints | | |

|

| Poor detail | Screen mesh too coarse | Use a finer mesh screen. |

|

| Paint too thin | Use less thinner |

|

| Worn screen | Replace screen. |

|

| Paint drying on screen | Hot, dry weather. | Add retarder to slow paint drying. |

|

| | Too much time between screening | Flood screen between passes. |

|

| Crazing | Stress from fabrication. | Review fabrication techniques. |

|

| | Flame polishing | Flame polish as last step. |

Notes:

Acrylic sheet is a combustible thermoplastic. Precautions

should be taken to protect this material from flames and high

heat sources.

The information and statements contained herein are

believed to be reliable, but are not to be taken as warranty or

representation for which CYRO assumes legal responsibility,

nor as permission, inducement or recommendation to practise

any patented invention without a licence.

Users should undertake sufficient verification and testing to

determine the suitability for their own particular purposes. Be

sure to follow manufacturers’ safety recommendations for

equipment and materials used with acrylic sheet.

Written by Grant LaFontaine, Sheet Products Technical

Service Manager for CYRO Industries.

For more information, contact CYRO Industries, 100 Enterprise Drive,

Rockaway, NJ 07866, 800-631-5384, Fax: 973-442-

6117, Web: www.cyro.com.

|