|

POLYCARBONATE SPOTLIGHT

Polycarbonates offer high impact strength over a

wide temperature range. They can be supplied in

high heat, FDA, UV grades and glass filled. They

are available in a wide variety of stock shapes and can be

custom extruded into unlimited profiles. Following is an

overview of a variety of polycarbonate materials offered

by some of the industry's leading suppliers.

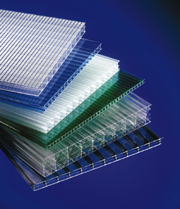

Sheets and Panels

AmeriLux International,

LLC offers Coverlite®

and Thermoclear Plus®

multi-wall polycarbonate

sheets, Lexan® corrugated

polycarbonate panels, Agrilite

™ corrugated PVC panels

and Coverbord™ PVC

trim board material. All of

their sheets feature the latest

in product technology

and are backed by a 10

year warranty.

multi-wall polycarbonate

sheets, Lexan® corrugated

polycarbonate panels, Agrilite

™ corrugated PVC panels

and Coverbord™ PVC

trim board material. All of

their sheets feature the latest

in product technology

and are backed by a 10

year warranty.

Lexan Thermoclear Plus is the next generation of multiwall

polycarbonate sheeting that has been produced in

Europe for over 24 years. It will maintain its clarity and

mechanical properties up to 5 times longer than competitor’s

products.

AmeriLux offers

Thermoclear Plus

in 8 mm twin

wall, triple wall,

solar control and

UV 2 sided. It is

also available in

25 mm six wall

UV 2 sided.

Thermoclear Plus

in 8 mm twin

wall, triple wall,

solar control and

UV 2 sided. It is

also available in

25 mm six wall

UV 2 sided.

Coverlite corrugated MR 9” and MR 12” polycarbonate

panels are designed specifically for the metal roofing

industry. Coverlite polycarbonate panels are perfect for

skylights and sidelight applications.

Their new Agrilite PVC corrugated liner panels are

designed for hog barns, food processing, dairy farms and

storage sheds. These liners come in an attractive high-gloss

white finish and offer a scratch resistant surface, high

impact strength and excellent resistance to chemicals.

Coverbord PVC foam trim boards are designed for trim,

fascia or detailed moldings. It is available in wood grain,

matte or smooth finish.

For additional information, contact Tami Churchill Voss,

AmeriLux International, LLC, 1212 Enterprise Drive, De

Pere, WI 54115, 888-602-4441/920-336-9300, Fax:

920-336-9301, E-mail: ameriluxtami@aol.com, Web:

www.ameriluxinternational.com.

Multiwall and Corrugated

Sheet

Now it’s easier than ever

before to rely on CO-EX for

a broad range of products including

Macrolux® Multiwall

Polycarbonate Twin, Triple, 4, 5,

and M-Wall sheet and Rooflite

® Corrugated Polycarbonate

sheet and profiles.

and M-Wall sheet and Rooflite

® Corrugated Polycarbonate

sheet and profiles.

CO-EX Products feature advanced

technology and product

development with superior service

that comes with a smaller, close-knit operation.

Macrolux Multiwall Twin, Triple, 4, 5 and M-Wall Polycarbonate

sheet is superior to standard polycarbonate sheet

products due to its strong, multilayer construction. These

layers provide increased thermal insulation and strength

while maintaining high light transmission. Heat reflecting

Macrolux Athermic reduces heat buildup in conservatories,

greenhouses, sunrooms and other glazed buildings, reducing

cooling costs and energy requirements.

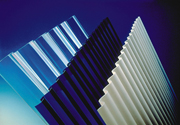

Rooflite Corrugated Polycarbonate sheets are flexible

and lightweight for easy installation and are extremely

durable. Rooflite is available in Greca, Sine Wave, Arc

Wave and RoofliteMB® which fits into metal roofing profiles

for effective, economical skylights.

CO-EX’S BDL® is a system of modular panels used to

create vertical, sloped and curved skylights, vertical wall

panels and interior systems. Thanks to a wide range of

accessories, the system is versatile and easy to install.

CO-EX Corporation serves the horticultural, architectural,

metal buildings, plastics, signage and home improvement

markets.

For additional information, contact Janice Pravorne, COEX

Corporation, 5 Alexander Drive, Wallingford, CT 06492,

800-888-5364/203-679-0500, Fax: 203-679-0600,

E-mail: coexcorp@aol.com, Web: www.co-excorp.com.

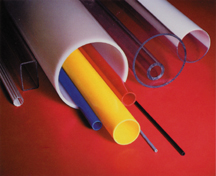

Tubes up to 14”

Futurplast manufactures clear polycarbonate tubes ranging

from 1/4” in diameter to 14” with 1/16”, 1/8” and

1/4” wall thicknesses. These products are stocked at their

strategically located distribution warehouses in Chicago, Los

Angeles, Tampa, Houston, Seattle, New Jersey, Albuquerque,

Columbus and Montreal. If you are looking for one 10” tube with a 1/4” wall and need it

overnighted to you, Futurplast

has got it and will get it to you

when you need it.

1/4” wall thicknesses. These products are stocked at their

strategically located distribution warehouses in Chicago, Los

Angeles, Tampa, Houston, Seattle, New Jersey, Albuquerque,

Columbus and Montreal. If you are looking for one 10” tube with a 1/4” wall and need it

overnighted to you, Futurplast

has got it and will get it to you

when you need it.

Futurplast is a distributor

committed a one-stop shopping

destination for clear

polycarbonate tubes as well

as clear, colored and frosted

“P95” acrylic products, offering

a large selection of in-stock rods and profiles.

Colored polycarbonate tubes are also available on

request.

For additional information, contact Joseph Sorella or

Lisa Houle, Futurplast Extrusions, 3435 Pitfield Blvd.,

St-Laurent, QC, Canada, H4S 1H7, 888-812-9075, Fax:

866-388-2955, E-mail: info@futurplast.ca, Web: www.

futurplast.ca.

Multi-wall Flat Sheets

Gallina USA, entering its 6th year of operation in the

United States, has been producing multi-wall polycarbonate

flat sheets at its location in Janesville, Wisconsin

since April 2007.

They are capable of producing from 4 mm through 25

mm, with a 2, 3, 4,

or 5 layers depending

on the thickness.

Gallina can

also offer custom

sized panels for a

minimum required

quantity.

They are capable of producing from 4 mm through 25

mm, with a 2, 3, 4,

or 5 layers depending

on the thickness.

Gallina can

also offer custom

sized panels for a

minimum required

quantity.

Later in 2008,

Gallina plans to introduce

panels with anti-fog properties for greenhouses

and other applications that require the maximum amount

of visibility and clarity. Gallina panels can be used for a

wide variety of applications from skylights to windows to

canopies to sunrooms. They are also a supplier of storm

panels for home and business protection against the

threat of severe or hurricane weather. The storm panels

have both Florida state and Miami-Dade approval. Gallina

also offers a variety of tongue and groove and standing

seam panels.

For additional information, contact Betty Reed , Gallina

USA, LLC, 4335 Capital Circle, Janesville, WI 53546,

608-531-0450, Fax: 608-531-0451, E-mail: betty@gallinausa.

com, Web: www.gallinausa.com.

Full-Service Converter

Green.tek is a leading, full-service, “cut-and-ship converter”

of hard-to-inventory polycarbonate sheets for the

commercial greenhouse, architectural and construction

markets. Green.tek provides cost-effective, highly efficient

warehousing and logistics services, as well as professional

sales and service capabilities to the plastic distribution market

segment. Partnered with Palram’s manufacturing

expertise in the USA, Green.tek has positioned itself as the

leading polycarbonate supplier in the industry based out

their 220,000 square foot facility in centrally located

Wisconsin. Green.tek offers multi-wall stock ranging from 4

mm to 32 mm in clear and a variety of colors. They can cut

and ship orders within 2 to 3 days and have no minimum

order quantity.

For additional information, contact Erin Kelly,

Green.tek, Inc., 417 East Fulton Street, Edgerton, WI

53534, 800-747-6440/608-884-9454, Fax: 608-884-

9459, E-mail: erin.kelly@green-tek.com, Web:

www.green-tek.com.

Flat Sheet

Palsun®, from

Palram Americas presents the transparency

of glass at less than half the weight, combined

with unmatched strength. PALSUN can be cold

bent, fabricated and/or formed, making it ideal for applications

such as barrel vault roofing, roof (sky) lights, architectural

roofing and glazing. Clear, translucent or opaque, sheets are also ideal as machine guards, sound barriers

and safety glazing.

It is available in several forms including UV protected on

one or both sides, embossed

(E102, prismatic, hair cell), with a

higher fire resistant rating, in

matte on one side and with abrasion

resistance on one or both

sides.

Sheets are

available

48” x 96”,

60” x 96”

and 72” x

96” in thicknesses of 0.04”, 0.06”

and unit values from 0.08” to 0.5”.

Multi-Wall Textured

Sheet

Sunlite® HG polycarbonate sheets,

from Palram Americas, combine

the benefits of a multi-wall polycarbonate

sheet with an attractive textured

finish that looks similar to

hammered glass, hence the HG

moniker. The sheet provides highly

diffused light transmission and a

semi-private transparency, allowing

for multiple uses. It is ideal for architects,

display manufacturers, fabricators

and contractors looking for

something special, but cost-effective

and easy to use.

The sheet

is impact

resistant,

lightweight

and easy to

work with, is

available in

many thicknesses

for

many uses

and is weather

and UV resistant for long life.

Sunlite HG is also extremely flexible

to allow vertically positioned panels

to conform to arched construction.

For additional information, contact

Stan Schultz, PALRAM Americas,

Inc., 916-989-2615, Fax: 916-

290-0229, E-mail: stan.schultz@

palram.com, Web: www.

palramamericas.com.

Tubing & ProfilesPetro Extrusion Technologies, Inc. (PET, Inc.) is a custom

and stock tubing and profile extruder of engineering

grade thermoplastics. They specialize in a wide

range of compounds including general purpose, UV, FDA

and high heat grades of polycarbonate.

PET, Inc. can custom extrude clear and colored polycarbonate

tubing from 1/16” to 8” in a variety of shapes and wall thicknesses. They also

custom extrude polycarbonate

profile extrusions,

offering an extensive selection

of standard colors with

color matching capabilities.

For additional information,

contact Sales, Petro

Extrusion Technologies,

Inc., P. O. Box 99, Garwood, NJ 07027, 800-229-3338/

908-789-3338, Fax: 908-789-0434, E-mail: rpetro@

petroextrusions.com, Web: www.petroextrusions.com.

Mirror

Plaskolite, Inc. offers polycarbonate

mirror sheet in .118”

and .236” thickness, in a sheet

size of 48” x 96”. It can be easily

fabricated, saw, router or laser

cut. Polycarbonate mirror is recommended

for those applications

requiring high impact strength,

heat and flame resistance.

A scratch-resistant coating is available for those more

demanding applications requiring abrasion, stain and solvent

resistance.

For additional information, contact Jonda Baldwin,

Plaskolite, Inc., P.O. Box 1497, Columbus, OH 43216,

800-848-9124, Fax: 877-538-0754, E-mail: plaskolite@

plaskolite.com, Web: www.plaskolite.com.

Rod, Plate & Tube

Plastifab Industries manufactures standard stock

shapes, rod, plate and tube and custom profiles in

polycarbonate. Available in utility, specialty and engineering

grades, polycarbonate offers superior impact and

toughness, clarity, high mechanical strength and rigidity

and good thermal properties.

For additional information, contact Plastifab Industries,

7777 Route Transcanadienne, Montreal, PQ, Canada H4S

1L3, 800-361-4774/514-325-9840, Fax: 514-325-5222,

E-mail: infoprod@plastifab.ca, Web: www.plastifab.ca.

Resistant Glazing

MAKROLON HYGARD® bullet resistant glazing from

Sheffield Plastics Inc., a Bayer MaterialScience

Company, offers bullet resistant containment up to UL

752 Level 3. It also

offers optical clarity and

abrasion resistance.

MAKROLON HYGARD

BR laminates accomplish

this with three products:

BR750, BR1000 and

BR1250. They are rated

for security applications

requiring UL Listed Level

1, Level 2 and Level 3 bullet resisting glazing respectively.

All three products are clear, with custom colors available

upon request, and sizes range from 38”-60” in width

and 60”-96” in height, with custom sizes available.

Low Flammability Polycarbonate

Sheffield Plastics Inc., a

Bayer MaterialScience

Company, offers MAKROLON

® LF (Low Flammability)

polycarbonate sheet

material. It is ideal for applications

requiring flame

inhibiting polycarbonate

such as transparent interior

aircraft components, electronic enclosures, gaskets,

spacers, switchgears, electrical devices, thermoformed

equipment and other current-carrying components. The material is easy to form and can be easily die cut,

punched and sheared for the most demanding fabrication

needs. It features improved ductility and reduced brittleness

for superior impact strength, many times that of

float glass and acrylic. It is also UV stabilized and offers

excellent optics.

Standard clear and custom colors are available in

gauges ranging from .080” to .250”.

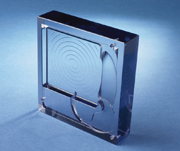

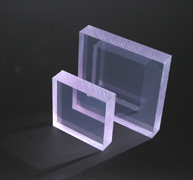

Widow Grade

Widow Grade

MAKROLON® WG (Window Grade) polycarbonate

sheet is an amorphorus thermoplastic made from

Bayer’s MAKROLON polycarbonate

resin. It is ideal for use

in a variety of applications,

ranging from containment to

fabricated parts. The sheet

ranges in thickness from .750”

thick up to 2”. Polycarbonate

sheet offers extremely high

impact strength and high modulus

of elasticity. Typical applications

include sight windows

for tanks/vessels, viewport windows,

medical parts and some military parts. The sheet

features excellent clarity, dimensional stability and good

dielectric properties. It offers excellent thermal performance

and is fabrication friendly.

For more information, contact Cindy Kahlstrom,

Sheffield Plastics Inc., 119 Salisbury Road, Sheffield,

MA 01257, 800-254-1707, Fax: 800-457-3553,

E-mail: cindy.kahlstrom@bayerbms.com, Web: www.

sheffieldplastics.com.

Machine Grade Rod &

Sheet

Röchling Sustaplast LP

offers Sustanat® PC polycarbonate

machine grade

rods and sheets available

from stock in natural, black

and glass-filled 20%. Rods

range from 3/8” to 6” diameter

(10’ lengths) and sheets

1/4” - 4” (24” x 48”). Custom

sizes and cut-to-size pieces

are also offered on request.

For additional information, contact Tony Caballero,

Röchling Sustaplast L.P., 216 Philips Road, Exton, PA

19341, 800-832-6787/484-875-9040, Fax: 484-875-

9030, E-mail: tcaballero@sustaplast.com, Web: www.

sustaplast.com.

Extrusions

The Spiratex Company’s polycarbonate extrusions are

manufactured from lightweight, flame retardant,

durable thermoplastic compounds. They custom extrude

polycarbonate parts in

clear or custom colors.

Glass fiber reinforced and

modified polycarbonate

grades are also available.

Parts that are typically

fabricated can often be

custom engineered and extruded to produce more costeffective

solutions and reduced manufacturing operations.

grades are also available.

Parts that are typically

fabricated can often be

custom engineered and extruded to produce more costeffective

solutions and reduced manufacturing operations.

Architectural finishes are an example of a good use of polycarbonate;

Light casings, railings, handles, support stands,

etc. are all easily manufactured by Spiratex. polycarbonate is

also a good choice for electronic applications when moisture

and impact resistance, rigidity and transparency are critical.

This material delivers the transparency of glass at half the

weight, superb impact resistance; it’s practically unbreakable,

has a wide service temperature range, high clarity and

light transmission. Spiratex will also manufacture polycarbonate

in food grades that are compliant with FDA, NSF,

Canada AG and USP Class VI regulations.

Spiratex is committed to living up to their reputation of

being a reliable source for the production of unusual, difficult

projects. Their experienced team has the ability to

customize polycarbonate profiles and/or tubes to meet

your particular requirements. Their technicians are highly

trained to produce quality products, and take pride in

being involved with some of the most challenging projects

in the world.

For additional information, contact Connie Buick, The

Spiratex Company, 1916 Frenchtown Center Drive,

Monroe, MI 48162, 734-289-5226, Fax: 734-289-4804,

E-mail: cbuick@spiratex.com, Web: www.spiratex.com.

Polycarbonate Shapes

Trident Engineering Plastics produces UV-stabilized

clear Optical Machine Grade polycarbonate plate up

to 2.00” thick in sizes of 24” x 48”, 48” x 48”, 48” x 72”

and 48” x 96”. Also included in this new product line are

natural and black machine grade plate up to 4” thick,

white machine grade plate up to 2.50” thick and glassreinforced

polycarbonate plate up to 4.00” thick in sizes

of 12” x 48” and 24” x 48”. Custom sheet sizes and cut to

size blanks are also available.

Trident Engineering Plastics produces UV-stabilized

clear Optical Machine Grade polycarbonate plate up

to 2.00” thick in sizes of 24” x 48”, 48” x 48”, 48” x 72”

and 48” x 96”. Also included in this new product line are

natural and black machine grade plate up to 4” thick,

white machine grade plate up to 2.50” thick and glassreinforced

polycarbonate plate up to 4.00” thick in sizes

of 12” x 48” and 24” x 48”. Custom sheet sizes and cut to

size blanks are also available.

Trident’s polycarbonate

stock shapes feature excellent

impact resistance, low

moisture absorption, excellent

dimensional stability and

a heat deflection temperature

of 270ºF at 264 psi.

Low internal stress levels

make Trident’s polycarbonate

stock shapes easy to machine

without the need for secondary annealing. Typical applications

for this material include control panels, electrical

components, manifolds and housings for use in medical,

semiconductor and industrial machinery of all kinds.

For additional information, contact Dean Cadic, Trident

Engineering Plastics Inc., 215-946-3999, Fax: 215-

946-0333, E-mail: sales@tridentepp.com Web: www.

tridentepp.com.

Polycarbonate Sheet &

Rod

Zelux® polycarbonate

from Westlake

Plastics is a tough,

transparent engineering

plastic with excellent

dimensional stability

and good strength and stiffness over a wide range of

service temperatures.

Zelux is often used for structural

applications where

clarity and impact strength are essential, including lenses,

manifolds, site glasses and machine guards. It is also used

for a wide variety of electrical applications since it has low

moisture absorption, good insulating properties and an

excellent flammability rating. Zelux is also easy to

machine, fabricate, paint and glue.

applications where

clarity and impact strength are essential, including lenses,

manifolds, site glasses and machine guards. It is also used

for a wide variety of electrical applications since it has low

moisture absorption, good insulating properties and an

excellent flammability rating. Zelux is also easy to

machine, fabricate, paint and glue.

Zelux is available in several formulations: Zelux W is the

window grade and is optically clear. Zelux M is a machine

grade and comes in natural and black. All are available in

sheet sizes from 3/8” up to 2 1/2” thick in 48” x 96” sheet

sizes. Sheets sizes 48” x 120” and 60” x 120” are available

on a custom quote basis. Zelux M sheet is also available

in 24” x 48” sheet sizes up to 4” thick in both natural

and black. All Zelux M products are stress relieved.

Custom quotes are available in 18” widths up to 6” thick.

In addition, 10, 20, 30 and 40% Glass Filled Black Zelux

is available in the above sheet sizes. Custom quotes for

colors, FDA and other grades are available upon request.

For additional information, contact Gary D. King,

Westlake Plastics Company, P.O. Box 127, Lenni, PA

19052, 800-999-1700/610-459-1000, Fax: 610-459-

1084, E-mail: gary@westlakeplastics.com, Web: www.westlakeplastics.com.

|