|

Going Green: Reduce & Reuse through Optimization and Remnant Tracking

ÓGreenÓ itÕs the latest buzzword sweeping corporate

offices all across North America. The boss wants

to ‘go green,” the accountants agree that it sounds

like it could save money; marketing says green sells and

sales says consumers are demanding ‘green’ products.

“So, let’s do it” everyone agrees, “Let’s go green!”

like it could save money; marketing says green sells and

sales says consumers are demanding ‘green’ products.

“So, let’s do it” everyone agrees, “Let’s go green!”

Three solar panels, one Toyota Prius and a wind operated

toilet later and the bottom line has not budged. The

customers are not beating down the doors. Sales is playing

table football rather than answering phones. What

went wrong? When did going green get so difficult?

Part of what makes being a green-friendly company so

frustrating is that it is hard to separate green trends from

truly green investments. Purchasing hybrid cars for business

trips might reduce a carbon footprint or two, but it

doesn’t really help a company produce products efficiently

and sustainably.

Solar panels on

the roof may cut

down on electricity

taken from the

grid but they don’t

address the other

wasteful and

inefficient elements

of production.

True green investments

not only

reduce the environmental

impact of a

company, they also

improve the nuts and bolts

aspects of production. They must be sustainable and provide

long-term or permanent benefits, and they should be

firmly tested and proven rather than trendy or gimmicky.

Aggressively lean companies have pursued such solutions

for years, both in software designed to tweak productivity

and in machines built for maximum efficiency. In other

words, true green tools have always been available, but

only now, as a larger conscience for conservation takes

shape, have they found a wider market.

The plastics industry has a lot to gain by going green as

quickly as possible. It’s not just a chance to alter public

perception of plastics in general; it’s also a chance to

implement time and material saving practices and technology

that can make the difference between a modern,

efficient company and

a lumbering, soon-tobe-

obsolete one.

Two options for

green technology exist

that are particularly

well-suited for the plastics

industry: optimization

and scrap recycling.

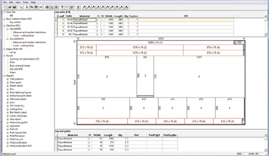

Of the two, optimization software is significantly easier to

learn and implement. Using a typical optimizer is as simple as

installing the software and entering a few basic parameters.

The optimizer typically requires a cut list of parts and a raw

material inventory in order to produce results, which come in

the form of optimized cutting patterns. The quality of the optimized

patterns depends on the level of sophistication of the optimization algorithm

powering the software.

Better algorithms, and

therefore better software

packages, will typically

cost a littlemore than bargain

bin programs.

Additionally, most

optimization packages

available today are

offered with optional

post processors for CNC

panel saws. The post

allows optimized patterns

to be sent electronically

to the saw for cutting and eliminates error prone

and time-consuming manual entry of cutting instructions

at the saw. The boost in saw productivity alone can cover

the cost of the software within a single fiscal year. Add to

that the improvement in material efficiency, accuracy of

reporting and estimating, as well as a range of other benefits,

and optimization easily becomes one of the best software

investments a company can make.

allows optimized patterns

to be sent electronically

to the saw for cutting and eliminates error prone

and time-consuming manual entry of cutting instructions

at the saw. The boost in saw productivity alone can cover

the cost of the software within a single fiscal year. Add to

that the improvement in material efficiency, accuracy of

reporting and estimating, as well as a range of other benefits,

and optimization easily becomes one of the best software

investments a company can make.

The second, more intensive option, often goes hand-inhand

with optimization software. Scrap recycling is a logical

method to improving material efficiency and reducing

waste material. In a typical system, usable scrap pieces

from a previous job are added back into inventory for

future use. The complexity of tracking scrap pieces and

having them on hand when called for can scrap (no pun

intended) even the best intentions and meticulous organization.

Production won’t wait for Bob to hunt down piece

number 1249B from the chaos in the warehouse, they’ll

just grab a fresh sheet. Over time, the discrepancy between

inventory actually on hand and inventory according to the

software grows so large than scrap

recycling is abandoned, if not officially,

then certainly in practice on

the shop floor.

Fortunately, technology has

advanced and the gap between

virtual and real, at least in terms

of real-time inventory tracking, is

diminishing. Most modern CNC

saw equipment can print part

labels in real-time, assigning

unique IDs stored in barcodes to

each part. The barcodes can contain

a variety of information that

can be retrieved quickly with a

commercially available barcode

scanner. Among other things, the

barcode can store the material

type and dimensions of a scrap

piece, which is laid aside until it

can be used. If the optimization

software is

capable of interacting

with bar code scanners, the saw

operator simply scans

the label on the scrap

piece he wants to use

and it is entered into

the optimizer’s inventory.

If the optimizer doesn’t

use it, the piece

remains on the shelf for

future use. Given the

relative cost of some

plastics, their multitude

of uses, and their infinite

shelf life, a sophisticated

scrap management

system save

untold thousands in raw material costs.

capable of interacting

with bar code scanners, the saw

operator simply scans

the label on the scrap

piece he wants to use

and it is entered into

the optimizer’s inventory.

If the optimizer doesn’t

use it, the piece

remains on the shelf for

future use. Given the

relative cost of some

plastics, their multitude

of uses, and their infinite

shelf life, a sophisticated

scrap management

system save

untold thousands in raw material costs.

No matter where you stand regarding the green movement,

optimization and scrap management are a good

place for plastics manufacturers to get their feet wet. If

you’re still skeptical of the “green revolution,” know that

optimization has been around for decades. A good quality

optimizer is the coalescence of many years of refinement

and testing, and can work on almost any machine in any

manufacturing environment. On the other hand, if you’re

fully committed to “going green” then optimization and

scrap management are a perfect fit, particularly in the

plastics industry. You don’t even have to drive the Prius

back to the dealership or cancel that order for the wind

operated toilet – every little bit helps!

Wishing you good luck in going green.

Written by David Talbot and Roman Liedel, Eurosoft.

For more information, contact them at Eurosoft,

Inc., 1628 Old Apex Road, Cary, NC 27513, 919-468-3003, Fax: 919-468-6374, E-mail: david@eurosoftinc.com, Web: www.eurosoftinc.com.

|