|

Bending the Rules

Continuous improvement takes on new meaning…

The Edge Finisher Company and Shannon introduced new technology in production format linear heaters. The new HRP/D automatic feed linear heater tripled the output of even the best current two sided heaters (Shannon’s own HRP and HRK series heaters).

The HRP/D is based upon the industry standard HRP format and incorporates an automatic feed system within the heating elements. Parts will continuously move through the machine as they are heated and exit the unit ready to be positioned into cooling fixturing. With the optional auto-load part magazine, this machine is a must for any volume producer.

The HRP/D is designed to accept parts 1/4" and under in thickness, up to 45" in depth, and 18" in heating width. The heating elements can be positioned for a minimum of 3/4" and a maximum of 45" between bends. For parts greater in thickness and bend width, the auto feed system can be disengaged for conventional operation of the machine.

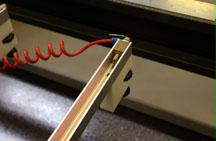

The HRP/D auto feed uses an adjustable speed, precision gear driven assembly to move the work through the machine (see following photo).

Non-abrasive neoprene belts carry the parts through the machine for scratch-free production. Upper rollers provide downpressure for stability and two adjustable stop bars provide axial positioning. The heating elements are nichrome wire set into aluminum reflective channels, and are infinitely positional within the 45" depth of the machine. The wires in the lower reflectors are vertically adjustable within the reflector body. (see photo below).

This allows the operator to vary the width of the heat zone for different material thickness and bend radius. Each heating element is individually controlled for maximum flexibility. The work surface is constructed of solid surface phenolic panels to ensure durability and resistance to heat transfer. This eliminates the need for water cooling adjacent to the heating elements (you need water near electrical components like a fish needs a bicycle). The HRP/D comes standard with two upper and two lower heating elements. Heating width is 6’ 6" (2m). The unit is constructed to meet CE safety standards, and, as with all of Edge Finisher’s machinery, carries a three-year warranty. Manufactured in the Netherlands, the HRP/D has proven to be a trouble-free performer throughout Europe. Through their exclusive distribution, this unit is now available in North America. Ask them about their discount for International Plastics Fabricators Association Members.

For more information, contact Darrell G. Bishop, Edge Finisher Company, 16 Stony Hill Road, Bethel, CT. 06801, 800-625-5863, 203-796-7923, Fax: 203-796-7924, E-mail: info@edgefinisher.com, Web: www.edgefinisher.com.

|