|

ROUTING: Fixturing & Routing Plastics With CNC Tooling

After proper bit selection, the most essential factors

in successful routing of plastics are optimum

programming techniques, solid fixturing and fast

speeds and feeds.

With the ever-increasing use of routers to machine

plastics, there has been a leap forward in the design of

tooling to produce high-quality finishes on a variety of

products. High-speed steel (HSS), carbide-tipped, solid

carbide and diamond tools have been manufactured in a

variety of geometries and sizes to rout most plastics.

Once an optimal bit is selected, however, achieving good

productivity still involves determining appropriate programming

methods, part fixturing and proper spindle

speeds and feed rates.

Programming Techniques

The goals of routing plastics are

high-quality finishes at fast feed

rates. Many programming techniques

will work well in the plastics

industry. The primary consideration

in plastics routing is the ability

to cut chips without them

rewelding themselves to the finished

surface. In softer plastics,

this can occur frequently and lead

to a poor edge finish. Preventing

this rewelding and producing a

smooth edge finish while attaining

fast feed rates is the secret to productive

plastics machining.

The key to preventing chips from

rewelding is simple — keep them

cool. The easiest method is fast feed

rates. But due to programming limitations,

this is not always practical.

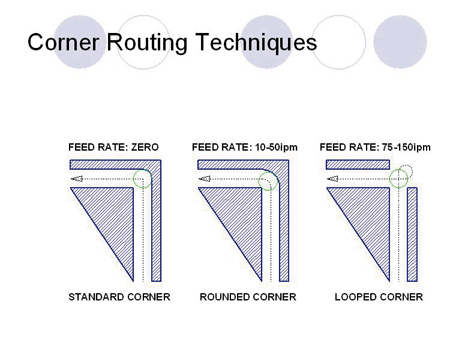

Most routers have acceleration,

deceleration and curve speed limitations

when cutting radii and corners.

Dead stops should be avoided

whenever possible. When cutting

outside corners, the router will stop

and dwell while changing directions.

At 18,000 rpm, a double edge tool will contact the part 600 times per

second and generate significant

amounts of heat.

This heat will not

only increase the instances of chip

rewelding, but will also decrease

the tool life and raise tooling

costs. A solution to tool dwelling is

to utilize “exit ramp” programming.

By programming corners as

outside loops, the tool is not

allowed to dwell and you can

achieve a square corner.

A second case when router bits

dwell is during the initial plunge of an inside cut. As the bit

is boring, it is continually re-contacting the cut surface, and

unless the bit is a spiral or has shear, the chips are not

being evacuated. This generates heat both from the rubbing

and from the fact that the bit must do extra work

recutting chips that remain in the hole. “Ramp in” cutting

can eliminate this effect by gradually plunging the bit (Zaxis

movement) as it begins its forward travel (Y- or X-axis

movement). If needed, the bit can travel backward after the

full depth of plunge to eliminate the cut ramp. The dwell

time involved with this reverse traverse is significantly less

than that involving a straight plunge and rout operation.

A final suggestion to reduce dwell time: when boring a

dedicated hole, actually rout the hole. Using a small diameter

bit, ramp into the hole in a circular

fashion and use a routing

action to cut the hole to size. This

allows you to hold tight tolerances

and prevents the occasional blowout

on the underside of a hole

when the plug is ejected.

While ramp programming to

remove dwell time may seem to

increase the routing path, the higher

production feed rates that are

attainable, along with the increased

tool life, should make the operation

economically attractive.

Assuming there are no software restrictions, if chip

rewelding is still a problem after removing dwell points,

move from HSS tooling to solid carbide as this will enable

an increase in feed rate. Increasing feed rates can reduce

the instances of chip rewelding.

Sometimes because of part configuration, thickness, or

composition, it is difficult to produce a high-quality edge

on a finished part. From a programming standpoint, there

are techniques that can be used to increase finished-edge

quality. A rough cut and finishing pass combination works

well on many thicker plastics. By leaving approximately

0.080 inch on the edge with a roughing tool, a finishing

tool can clean up the edge and have enough material to cut, so that the tool remains stable and does not begin to

chatter. An added benefit is that the number of pieces

produced per finishing tool is greatly increased while the

more durable roughing tool is the one subjected to

increased wear.

When cutting nested or mirrored parts with a single

pass, operators may notice a decrease in surface finish on

one of the exposed edges. Frequently, surface finish can

change depending on whether the tool is presented to the

material in a climb-cut configuration or a conventional cut

configuration. Generally, conventional cutting yields a better

edge, unless a finish pass is used, in which case the

second pass can be a climb cut. If nested part cutting

does yield problems, the cut can

be accomplished in two passes

with the smaller diameter tool.

The first pass will finish cut one

side and then the tool travel will

be reversed and the remaining

side will be finish cut.

Finally, when cutting laminated

plastics or products that have an

abrasive layer, tool oscillation can

greatly increase tool life. Materials

such as plastic laminated with aluminum

can cause a severe wear

line on both carbide and highspeed

steel. By oscillating the tool vertically (Z-axis) during

the cut, this wear can be spread over a larger area and

allow the bit to continue cutting before it is dull.

Fixturing

Quality production demands quality material, quality

tooling and quality fixturing. Fixturing must be solid and

reliable. Anything else will ultimately lead to poor edge

finish and reduced tool life or broken tools. That said,

there are specific techniques and configurations that can

lead to a more efficient and practical hold-down system.

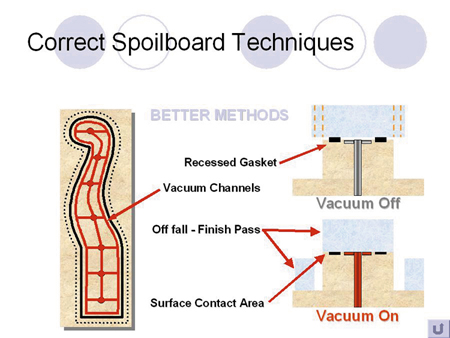

Vacuum hold-down is the most prevalent method in the

CNC industry today and it is important to get the most out

of the system. First of all, a

piece of MDF with weatherstripping

tape and a few holes

drilled in it is not adequate.

Vacuum hold-down with a spoilboard

is capable of extremely

rigid part fixturing but only if

utilized correctly.

Using the router to create a

grid connecting the vacuum

ports allows the vacuum to

reach all edges of the part to

be machined. This will increase

the holding power of the vacuum

system and allow better

edge finishes due to a rigid holding

configuration. Using proper gasketing

tape in an over-sized channel will also

increase the lifetime of the spoilboard.

If the tape used is not for gasketing

applications and has “memory,”

it will not expand back to its original

state after repeated compressions

and the vacuum system may

begin to bleed off. Additionally, if the

channel is not oversized, when the

tape is compressed by the part it will

have nowhere to go. This may prevent

the part from contacting the vacuum

surface and allow vibration to occur.

Other improvements for spoilboards

include building dedicated

boards for particular parts. One

example involves cutting parts that

have small scrap pieces. When the finished

part is cut, excess material (outside

corners, plugs from boring, etc.)

can become missiles if they are too

small to be held effectively by the vacuum

pressure. As they chatter on the

table they can contact the router bit

and either cause damage to the bit or

be “shot” off the table. To eliminate

this problem, build up the spoilboard

in certain areas and seal the edges so

that the part is actually being held on

the top of a pedestal or plateau. In this configuration, the

excess material will fall to the main spoilboard when cut

and be clear of the cutting tool.

Dedicated spoilboards can also be useful when material

composition demands a downcut spiral or shear tool.

Soft plastics require that the chips be cleared quickly and

aggressively. When using a downcut bit without a raised

spoilboard, the chips are not able to clear out of the cut.

By routing channels in the spoilboard below the areas to

be cut, it is possible to give the chips a place to clear.

If these configurations still do not provide sufficient

holding force and safety, the parts can be held with riveted

tabs or screwed into the spoilboard through the center

of scrap portions. This is the last resort due to the fact

that set-up time per piece is increased and throughput is

reduced.

Speeds And Feeds

If the part to be machined is fixtured securely and the

correct tool has been selected for the material, spindle

speed and feed rate will be the determining factors on the

finished quality of the part. Speeds and feeds can vary

greatly depending on router horsepower, tooling and part

composition. However, it is possible to make an educated

guess at the correct ratios and to then fine-tune the finish.

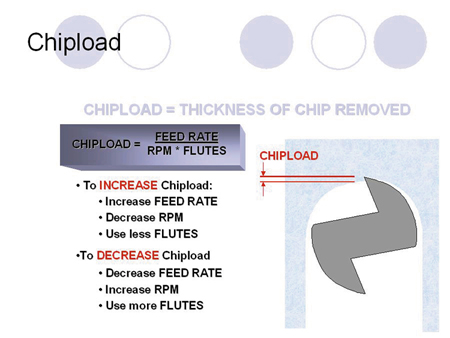

The defining ratio of speed and feed combinations is

“chipload.” Chipload is the thickness of the chip that is

removed by a cutting edge per revolution.

In effect, increasing the chipload will cause a larger chip

to be removed. The larger the chip removed, the more

heat that is removed with it and the longer the tool life.

The primary means of increasing chipload is to increase

the feed rate as this has the added benefit of increasing

the parts produced per hour.

Chipload can also be increased by lowering spindle

speed if feed rate is already at a maximum. Decreased

chipload means the number of times that a cutting edge

is presented to the workpiece is increased. Every router

bit edge has only a finite number of times it can be used

to cut before it is considered dull. Therefore, the highest

chipload that will produce an acceptable finish should be

used to prolong cutter life.

Since CNC operators do not think in terms of chipload,

but rather speeds and feeds, it is useful to have some

“rules of thumb” when determining rates. For the following

examples, a spindle speed of 18,000 rpm is assumed. For

soft plastics, solid carbide spiral tools that have geometry

specifically for cutting that type of plastic can be run at

approximately 300 inches per minute (ipm). Solid carbide

“O” flutes should also be run that fast in order to clear the

chips. If finish begins to degrade, the spindle speed can be

increased in order to maintain the same production rate.

High-speed steel “O” flute tools require slower feed rates

in order to prevent the bit from deflecting and causing

chatter or knife marks.

Harder plastics work well with low-helix tools that have

been designed to break the plastic chips away cleanly.

These tools can be run at around 300 ipm. Double-edged

“V” flute tools can run anywhere from 125 ipm to 250

ipm, depending on style and bit composition, and also

produce an excellent finish. It is important to understand

that in all cases, whether routing hard or soft plastics,

chips (not dust) must be made. Large chips will not reweld

to a cut surface and will prolong the life of the tool. If the

cut waste that is produced is dust, that means the chips

have been recut numerous times or the chipload is too

low. The tool life will suffer, as well as the edge finish.

Fiber-reinforced plastics are different from other types

of plastics in that it is very difficult to determine the type

of chip being produced. Because of the structure of materials

such as fiberglass, aramid and carbon fiber compounds,

chips are not formed during the cutting process.

In these instances, it is best to run the bit as fast as possible.

The cooler the bit is when finished, the longer the

tool life can be expected of the bit.

If, despite adjusting speeds and feeds, the best cut still

produces a hot tool or causes occasional chip rewelding,

forced air can be used to evacuate the chips. First, make

sure the dust collection system is operating efficiently.

Then, use air forced through a directional nozzle to clear

the chips. Additionally, several companies manufacture

Venturi effect nozzles, which can drop the temperature of

the air charge and provide additional cooling as well as

chip evacuation.

With the ever increasing formulations of plastic in the

marketplace, there is going to be a continuing need for

high-quality machining and finishing work. After proper bit

selection, the most essential items to successful routing of

these materials involve optimum programming techniques,

solid fixturing, and fast speeds and feeds. Be sure

as much emphasis is placed on the tooling, fixturing and

programming as is placed on the CNC equipment that is

expected to utilize it.

Van Niser is Director of Plastic Application Engineering

at Onsrud Cutter. Readers are invited to send questions to

Van Niser at Onsrud Cutter, 800 Liberty Drive,

Libertyville, IL 60048, E-mail: vniser@onsrud.com.

For more information, click on the Author Biography link at the top of this page.

|