|

ROUTING: The Importance Of Spoilboards

The emphasis today in the fabricating and machining

of plastics is CNC — or computer numerical

controlled machines. These high spindle speed,

high feed rate machines accomplish a tremendous

amount of work in cycle times, which enhance productivity

and profitability. A great deal of time is devoted to the

selection of such machines and the appropriate tooling

and accessories, but the area of spoilboard methodology

is given less consideration. Without proper investment of

time in this critical area, the holding of parts to accomplish

maximum productivity becomes challenging at best.

Types of Spoilboards

The dedicated or discreet spoilboard

system has traditionally been

utilized over the years to machine

individual parts that are held by a

gasketed vacuum system. Unfortunately,

many times the process of adequately

constructing these spoilboards

has been ignored in the interest

of time. The use of a piece of MDF

or particleboard with holes drilled

inside an area encapsulated by selfstick

weather stripping does not meet

the demands placed on the parts in a

high-speed application. Consequently,

it is imperative to follow certain criteria

when building spoilboards to maximize

the part hold-down procedure.

First, the selection of gasketing

material is foremost in the process of

building substantial dedicated spoilboards.

This material should be quality

closed cell foam, which has the

ability to return to its original configuration

repeatedly under rigorous

machining conditions. Self-stick weather

stripping, which is open cell construction,

does not possess such

memory characteristics and should

never be utilized. The gasketing

material represents the perimeter of

the part configuration and must have

the resiliency and durability to maximize part rigidity and

reduce vibration. A good technical source for gasket material

and usage is at www.allstaradhesives.com.

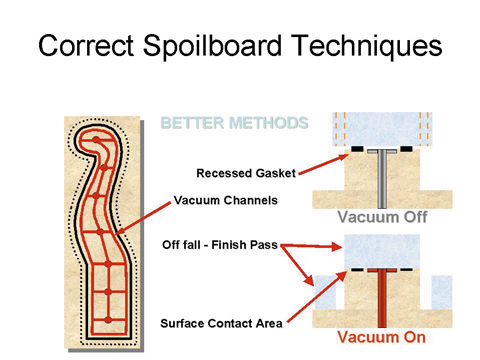

After the proper gasketing material is selected, a channel

should be routed into the spoilboard to establish the outside

perimeter of the part and as a recessed area for application

of the gasketing tape. This process allows the part to

be solidly held to the table surface, and prolongs the life of

tape. The source of vacuum is port holes drilled in the interior

of the gasket perimeter. In order to generate a larger

vacuum surface area the holes should be connected to a

groove routed just inside the gasket perimeter. This provides

an arterial flow to the outermost edge of the part and

substantially increases rigidity (Figure 1). Furthermore, the

actual spoilboard is often significantly impacted when constructed

of double-sided melamine board to reduce the

leakage of vacuum associated with raw board materials.

substantially increases rigidity (Figure 1). Furthermore, the

actual spoilboard is often significantly impacted when constructed

of double-sided melamine board to reduce the

leakage of vacuum associated with raw board materials.

The second type of spoilboard is universal vacuum, which

is also referred to as high volume, flow through or suck

through vacuum. This method distributes volume of vacuum

throughout the entire surface of low or medium density

spoilboard, and has gained popularity because of minimal

setup time. The process is utilized to cut parts from whole

sheets of raw materials, and is particularly effective on larger

parts where part movement is not a major concern.

However, smaller parts can become problematic with this

spoilboard approach and other techniques should be

employed to avoid part movement. Tab cutting and skin cutting

techniques are especially effective in dealing with small

parts. This involves leaving a tab or a thin layer of material

on the bottom of the part to hold them together. The tab or

skin portion is then removed in a secondary operation. This

process is slightly more time consuming, but the final

results are quality edges and less scrapped parts caused by

movement during the machining process.

Since the universal vacuum approach involves high flow

without the inherent benefits of dedicated spoilboards,

the opportunity for leaks and subsequent part movement

is always present. In order to minimize those kinds of

problems, additional techniques can be applied. Rubberized

paint can be applied to seal spoilboard edges.

Smaller diameter tools will minimize cutting pressure and

reduce larger open spaces on the cutting area.

Scrap

parts or plastic sheet can be used to cover open, unused

areas of the spoilboard when smaller than whole sheet

raw material is utilized. Furthermore, the spoilboard

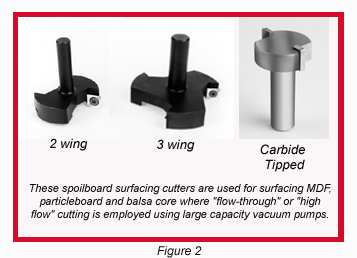

should be surfaced with a large diameter spoilboard surfacing

cutter. This process should be done initially to both

sides of the spoilboard before actual machining of parts to

increase porosity and ensure the surface of the board is

flat. The cutter is continually used to maintain those two

parameters and eliminate rout lines caused by the cutting

tool during the machining process (Figure 2).

Scrap

parts or plastic sheet can be used to cover open, unused

areas of the spoilboard when smaller than whole sheet

raw material is utilized. Furthermore, the spoilboard

should be surfaced with a large diameter spoilboard surfacing

cutter. This process should be done initially to both

sides of the spoilboard before actual machining of parts to

increase porosity and ensure the surface of the board is

flat. The cutter is continually used to maintain those two

parameters and eliminate rout lines caused by the cutting

tool during the machining process (Figure 2).

Criteria for Vacuum System

In addition to actual spoilboard, the vacuum system

should be constantly evaluated to guarantee optimum

performance. Rating this system should include the following

criteria:

Does the pump have enough suction? -

400 cfm w/15in Hg for flow-through systems.

- 80 cfm w/25in Hg for dedicated systems.

Are supply lines large enough? -

3 inch diameter minimum for flow-through systems, 4

to 5 inches recommended.

-

3/8 inch diameter for dedicated systems, 1/2 inch recommended.

Are there enough vacuum sources?

How many bends are in the supply lines?

Are potential vacuum leak areas and unused areas

sealed?

Regardless of which spoilboard application is utilized, it

is imperative to follow good construction and enhancement

techniques to ensure parts are held solidly. In the

world of high-speed machining in plastics, it is the only

method to produce quality parts on a consistent basis.

For more information, click on the Author Biography link at the top of this page.

|