|

ROUTING: Major Considerations in the Routing of Plastic

Before the process of routing or machining plastic,

the user must evaluate the capabilities inherent

to the operation.

Capability

The first consideration is in the area of machinery, which

can vary widely in the world of plastic fabrication.

Machines of choice include: air and electric routers, pin

routers and CNC machinery. These types of machines are

prevalent in sheet fabrication, thermoforming and rotational

molding operations throughout the plastic industry.

Air, electric and pin routers fall into the categories of

hand fed applications and present an entirely different set

of circumstances than a CNC application. Since these

machines are heavily influenced by the skill of the individual

operators, the tooling material of choice should be

high speed steel or carbide tipped with a steel shank.

These tool materials are more forgiving in a hand fed

application and less likely to fail than solid carbide, which

thrive best in the controlled environment of CNC.

Within hand fed operations, one of the more prevalent

machines is the air router. The air router has some characteristics

which have a direct effect on the tooling choices.

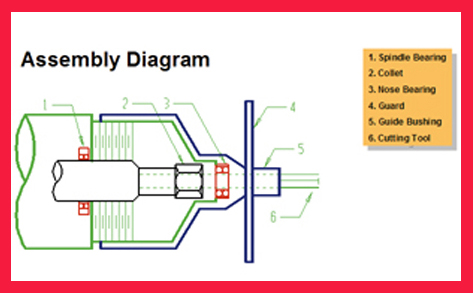

The diagram below, (Figure 1-Air Router Assembly

Diagram) illustrates that the air router has a nose or support

bearing, a guard and a guide bushing. All these features

have important functions but they necessitate the

use of router tooling specific to the air router.

These tools

must be manufactured with long enough overall length to

bottom out in the collet and extend beyond the guide

bushing while making contact with the work piece. Also,

the tools must be slightly undersized along the entire

length of the tool to pass smoothly through the support or

nose bearing. The forcing of on size tooling through the

support bearing alters the bearing and negates the function

of this critical mechanism, which adversely affects the

concentricity of the cutting tool. Consequently, it is important

to incorporate tooling properly toleranced for air

routers.

These tools

must be manufactured with long enough overall length to

bottom out in the collet and extend beyond the guide

bushing while making contact with the work piece. Also,

the tools must be slightly undersized along the entire

length of the tool to pass smoothly through the support or

nose bearing. The forcing of on size tooling through the

support bearing alters the bearing and negates the function

of this critical mechanism, which adversely affects the

concentricity of the cutting tool. Consequently, it is important

to incorporate tooling properly toleranced for air

routers.

CNC routers are extremely popular

among plastic fabricators with 3-axis

and 5-axis machines fulfilling a variety

of needs. Generally speaking, flat sheet

fabricators utilize 3-axis, while thermoformers

with a need to attack multishaped

parts at an angle, account for

most of the 5-axis machines. Solid carbide

is the tooling material widely utilized

because of it’s toughness and the

longevity of the cutting edge when chip

load is properly maximized.

Solid carbide

router tools are available in a

broad range of geometries and styles.

Sheet fabricators usually prefer upcut

spirals to aid in the extraction of

potentially soft plastic chips. On the

other hand, thermoformers with

formed fixtures tend to use straight

edge tooling, which has a neutral effect

on the part. Downcut spirals can be

utilized in some 5-axis applications but

the fixturing must be such that the

chips fall away from the part. If the

chips cannot fall freely from the part,

recutting of plastic chips can cause

welding to occur which is detrimental

to the part and the router tool.

Solid carbide

router tools are available in a

broad range of geometries and styles.

Sheet fabricators usually prefer upcut

spirals to aid in the extraction of

potentially soft plastic chips. On the

other hand, thermoformers with

formed fixtures tend to use straight

edge tooling, which has a neutral effect

on the part. Downcut spirals can be

utilized in some 5-axis applications but

the fixturing must be such that the

chips fall away from the part. If the

chips cannot fall freely from the part,

recutting of plastic chips can cause

welding to occur which is detrimental

to the part and the router tool.

Regardless of the type of machinery utilized, the ability

to properly hold the part is critical. The three methods

associated with part holddown include: mechanical i.e.;

clamps, dedicated and flow-through spoilboard systems.

Dedicated and flow-through are the two most prevalent

systems in the area of CNC routing. Flow-through has

become the most popular because of the ease of setup

but there is no question that the best approach to solidly

holding parts is a properly built dedicated spoilboard.

The savings in reworked parts, scrapped parts

and overall cycle time is well worth the

effort.

Lastly in terms of capability and machinery,

the machinery is only as good as its

maintenance schedule. The critical maintenance

on a router as it relates cutting tools

is the collet. Concentricity of the router tool

can only be accomplished with a clean and

well-maintained collet system.

Tool Selection

Once capability has been determined in

terms of properly maintained machinery

and rigidity of part to be machined, tool

selection becomes paramount.

Router

tools for plastic cutting are application and

material specific. In almost all cases, one

cutting tool cannot be utilized across a

variety of plastic material. Router

tools for plastic cutting are application and

material specific. In almost all cases, one

cutting tool cannot be utilized across a

variety of plastic material.

Generally speaking, plastic can be categorized

as either hard or soft plastic. Soft plastic will curl

a chip and hard plastic tends to produce a splintered

wedge, which is actually broken off in the machining

process. The use of “O” flute tools in straight and spiral

configuration with high rake angles and low clearance will

aid in eliminating the knife marks associated with soft

plastic. Hard plastic is best routed with

double edge “V” flutes, spiral “O” flutes

with hard plastic geometry, or two and

three edge finishers. These tools along with

the proper chip load produce a crater free

finish. Cratering in hard plastic occurs

when the shear strength of the material is

exceeded in the routing process.

The aforementioned tooling suggestions

are accurate starting points but extremely

general in nature. For specific tooling recommendations

by plastic material, log onto

the Internet at www.plasticrouting.com.

Once tool selection has been finalized,

chip load becomes a critical consideration.

Chip load or the actual thickness of

the chip is a function of the spindle speed

(RPM), the travel speed of the cutting

tool (IPM) and the number of cutting

edges of the tool. In plastic, there is a

very narrow range of chip load to maximize

finish and cycle time. Since finish seems to be one

of the most important factors in machining plastic, the

range falls between .004 and .012. However, finish is

always a personal decision and some applications may

warrant a larger chip load at the expense of finish to

increase productivity. In other words, do not be limited

by the recommended range but

use it as a guide.

Conclusion

Plastic material is showing up in

routing and machine shops everywhere.

It is a new material for many

and it cannot be machined with the

same tools or same methods used

for metal or wood. The systematic

process of considering machine

capability, tool selection and a functional

chip load, which is the outcome

of feed and speed, is critical.

Once this has been accomplished,

the user is prepared to enter the

world of machining plastic with confidence.

For more on spoilboards and

proper collet maintenance, see the Van Niser article archive on the left side of this page.

For more information, click on the Author Biography link at the top of this page.

|